Sandvik Coromant Unveils ATC System to Boost Machine Utilization and Efficiency!

By Ashutosh Arora

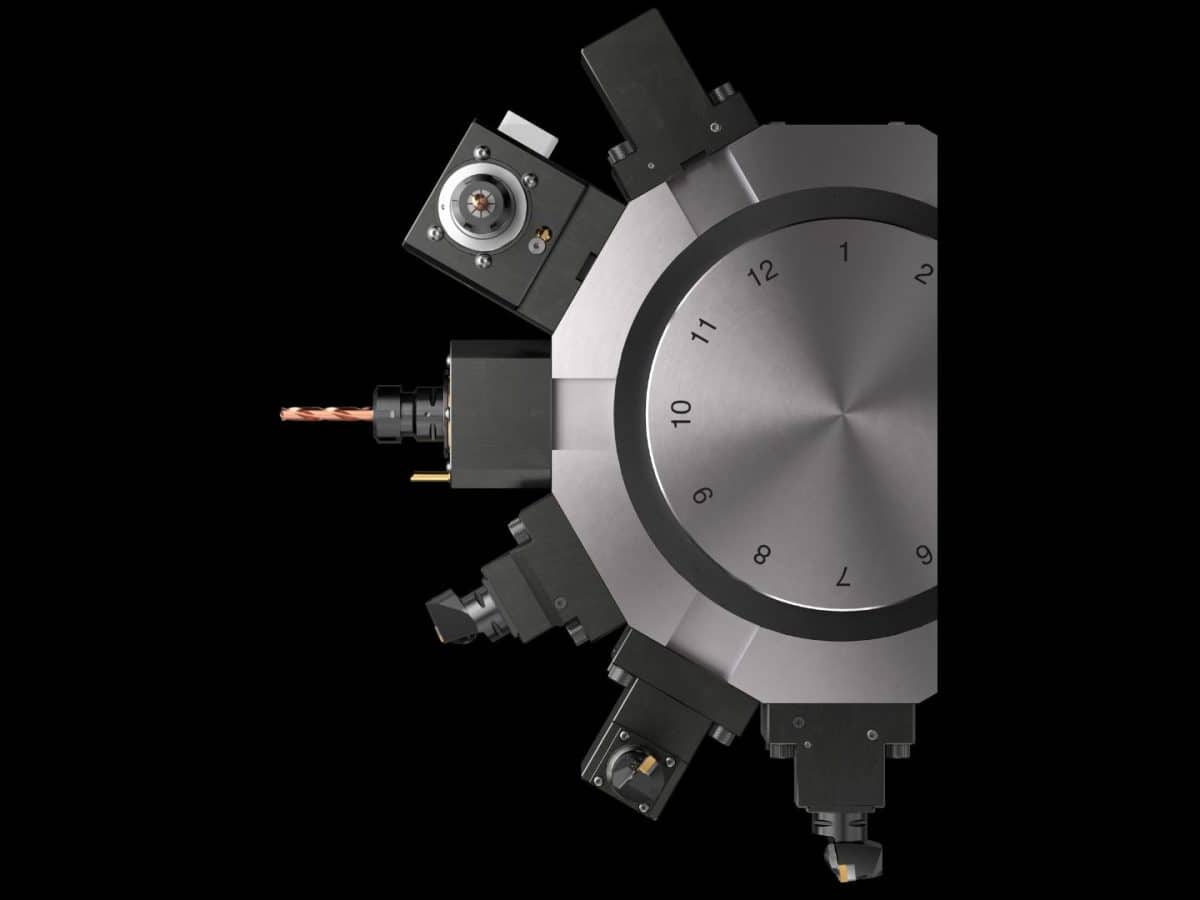

Sandvik Coromant has introduced a groundbreaking automatic tool change (ATC) system designed for its machine-adapted clamping units (MACU) in turning centers, enabling unmanned, fully automated production. This solution eliminates manual tool changes, improving machine utilization, and increasing output.

In complex part production, the time-consuming process of manual tool changes often leads to low machine utilization. Sandvik’s ATC solution addresses this by automating the process, enhancing productivity, and making manufacturing more efficient. The system provides notable sustainability advantages, reducing energy consumption, waste, and optimizing resource use. With machines operating at optimal levels, the ATC system reduces idle time, energy waste, and the risk of breakdowns, ultimately improving overall equipment effectiveness (OEE).

Applicable in turning centers and multitasking machines, the ATC system requires a MACU with a Coromant Capto interface, with specific turret configurations needed for turning centers and multitasking machines for full compatibility.