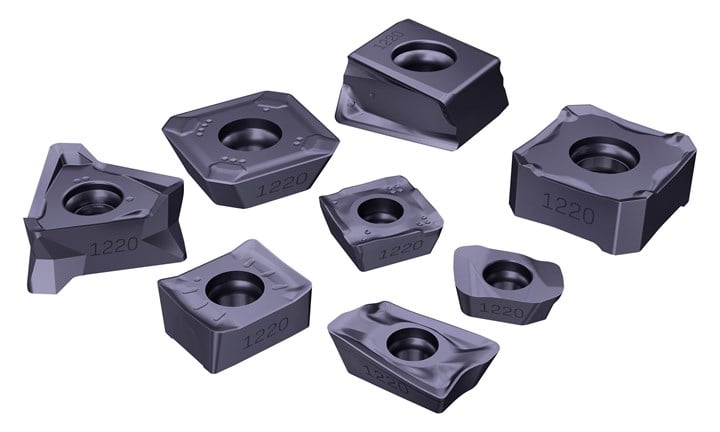

Sandvik Coromant Milling Insert Grade Enhances Cast Iron Machining!

Sandvik Coromant has expanded its milling portfolio with the introduction of the GC1220 indexable milling insert grade, developed specifically to address the machining challenges associated with nodular cast iron. Designed to deliver higher reliability, improved efficiency, and consistent performance, GC1220 is aimed at manufacturers seeking stable machining processes across a wide range of cast iron applications.

At the core of GC1220’s performance is an advanced nano-multilayer physical vapor deposition (PVD) coating created using Sandvik Coromant’s proprietary coating technology. This coating combines layers of TiAlN and TiSiN, resulting in a structure that enhances both wear resistance and edge-line toughness. The coating design helps the insert withstand abrasive conditions while maintaining cutting edge integrity, even under fluctuating thermal loads.

GC1220 is engineered to perform reliably in both wet and dry machining environments. Its resistance to abrasive wear and thermal cracking makes it particularly suitable for demanding production settings where process stability is critical. By reducing the risk of premature tool failure, the insert supports longer and more predictable tool life, enabling manufacturers to minimize downtime and maintain consistent output levels.

The grade is optimized for operations ranging from light roughing to finishing, making it a versatile choice for a broad spectrum of milling tasks. GC1220 performs effectively in general machining as well as more challenging applications such as square shoulder milling, machining of interrupted surfaces, skin conditions on cast components, and complex tool paths that place higher stress on cutting edges.

While GC1220 is primarily designed for nodular cast iron classified under ISO K3, its application range extends to malleable and grey cast irons in the K1 and K2 classifications. This flexibility allows manufacturers to standardize tooling across multiple cast iron materials, simplifying tool management and improving overall shop-floor efficiency.

By combining advanced coating technology with robust performance characteristics, Sandvik Coromant’s GC1220 milling insert grade supports higher productivity and more sustainable manufacturing. The longer tool life and predictable wear patterns contribute to reduced material waste and more efficient use of resources, aligning machining performance with modern production and environmental objectives.