Renishaw Equator-X 500: Redefining Shopfloor Process Control with Dual-Method Flexibility!

By Ashutosh Arora

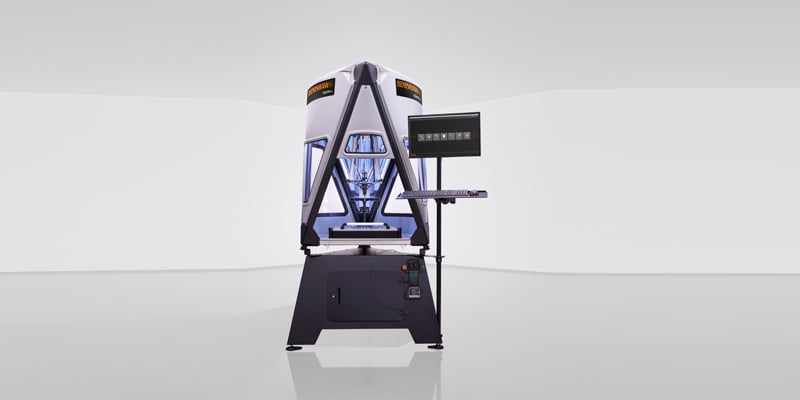

Renishaw Inc. has once again elevated shopfloor process control with the launch of its Equator-X 500 dual-method gaging system, designed to offer manufacturers unprecedented flexibility, precision, and speed in measurement and inspection. Built for the ever-evolving demands of modern manufacturing, the Equator-X 500 combines two powerful inspection modes — Absolute and Compare — within one system, enabling users to optimize measurement strategies for different production needs.

In high-mix, high-speed manufacturing environments, maintaining precision and throughput can be a constant challenge. The Equator-X 500 addresses this by allowing operators to choose the ideal inspection approach depending on batch size, design variation, and process requirements. In Absolute mode, the system achieves scanning speeds of up to 250 mm/s, making it ideal for first-off verification or at-line 100% inspection where accuracy and traceability are critical. Meanwhile, the Compare mode pushes scanning performance to an impressive 500 mm/s, catering to mass production scenarios where speed and consistency take priority.

At the heart of the Equator-X 500 lies Renishaw’s engineering excellence — a hexapod structure with independent drive and metrology frames that ensure rapid motion without compromising precision. The system’s use of carbon fiber metrology struts, linear motor drives, and the SP25M scanning probe underscores its capability to maintain accuracy even in fluctuating shopfloor environments. These design elements contribute to both rigidity and responsiveness, enabling continuous validation of the production process while improving inspection capacity and overall throughput.

Another standout feature is the system’s versatility in deployment. The Equator-X 500 can function as a standalone shopfloor measurement unit or be seamlessly integrated into an automated production cell, allowing manufacturers to adapt quickly to changing production demands. Whether inspecting complex small-batch components or handling high-volume runs, the Equator-X 500 ensures that process control remains robust, traceable, and efficient.

Ease of operation is also a defining factor. The system is powered by Renishaw’s intuitive Modus IM metrology software, offering a user-friendly interface for programming, reporting, and real-time monitoring. Operators can quickly switch between modes, analyze data, and ensure every component meets quality standards — all without extensive technical training.

In an era where manufacturers are under constant pressure to shorten cycle times while maintaining accuracy, the Equator-X 500 provides a strategic advantage. It bridges the gap between precision measurement and production efficiency, empowering businesses to maintain control of quality right on the shop floor. By combining speed, flexibility, and traceability, Renishaw’s latest innovation reinforces its position as a global leader in precision metrology solutions, driving smarter, more adaptive manufacturing processes for the future.