Predictive Quality: Revolutionizing Manufacturing with AI-Powered Quality Control

In manufacturing, maintaining quality control is vital, but traditional methods often lead to high non-productive times. However, a game-changing solution is emerging: Predictive Quality. This innovative approach leverages AI models to predict component quality in real-time during production, minimizing errors and boosting efficiency.

What is Predictive Quality?

Predictive Quality involves predicting component quality alongside the production process. By analyzing high-frequency production data with artificial neural networks (ANN), this method anticipates quality characteristics, such as form deviations, enabling early detection of process errors.

Suitable Data for Predictive Quality:

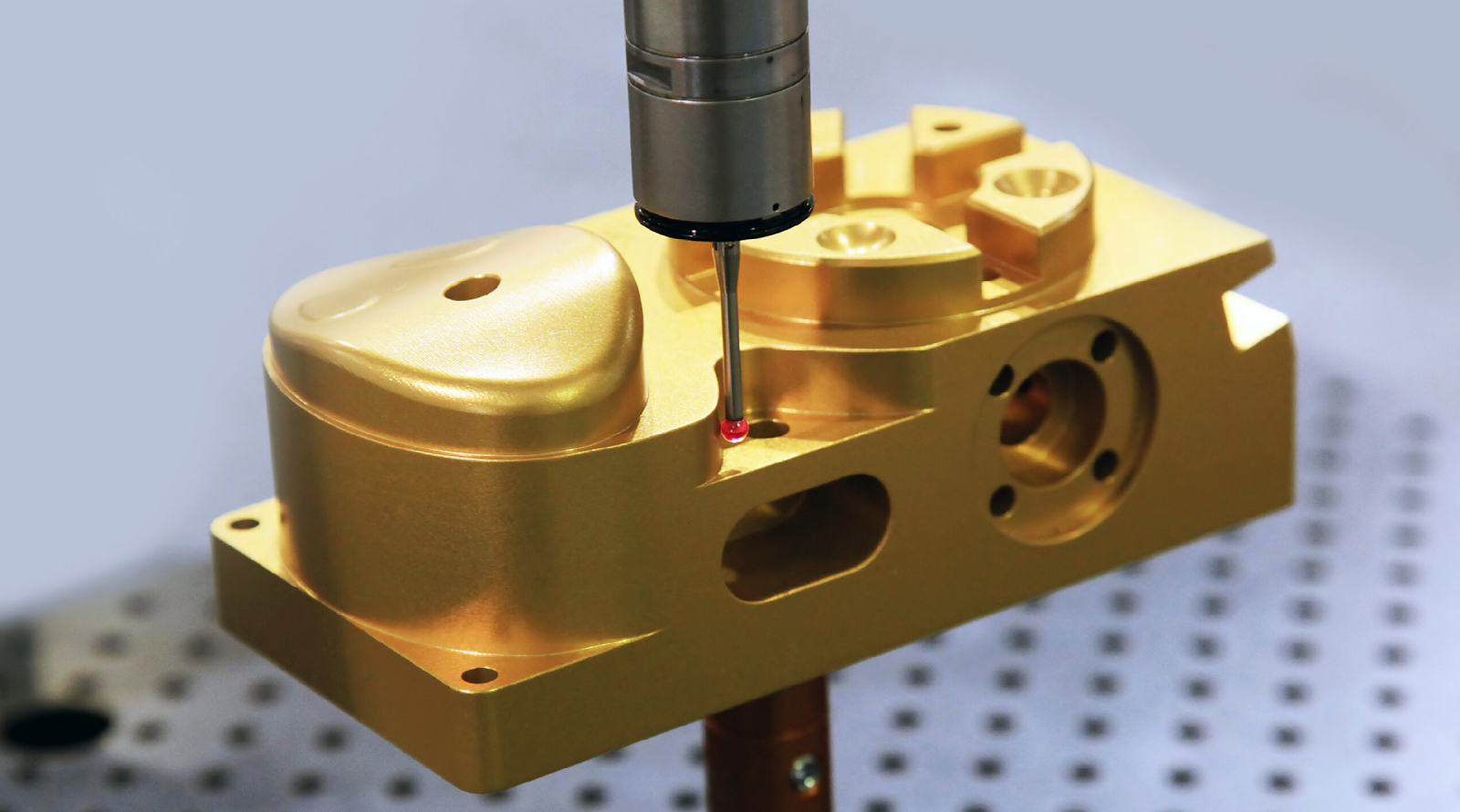

To implement process-parallel quality control, production data and quality assessment data are crucial. Machine drive currents serve as ideal production data, accessible through interfaces like Profibus or OPC UA. Additionally, quality control data, acquired from CNC-controlled measuring machines, ensures accurate predictions.

Training the Artificial Neural Network:

The ANN is trained using production and measurement data, employing supervised learning to establish correlations between inputs and outputs. This trained AI model then predicts quality characteristics based on new production data, enabling proactive quality management.

Companies Benefitting from Predictive Quality:

Predictive Quality offers significant advantages, particularly in series production, where frequent manufacturing processes occur. While it’s not suited for small batch sizes, it can predict shape and position errors across various manufacturing processes, enhancing overall quality control.

Conclusion:

Predictive Quality doesn’t replace traditional quality controls entirely but offers a valuable supplement. By quantifying predicted quality variables’ tolerance, manufacturers can assess the ANN’s accuracy and optimize quality control processes effectively.

For more insights, visit www.proki-hannover.de.

Original source from metrology.news