Platinum Tooling Launches Haas Multitool System to Maximize CNC Lathe Efficiency!

By Ashutosh Arora

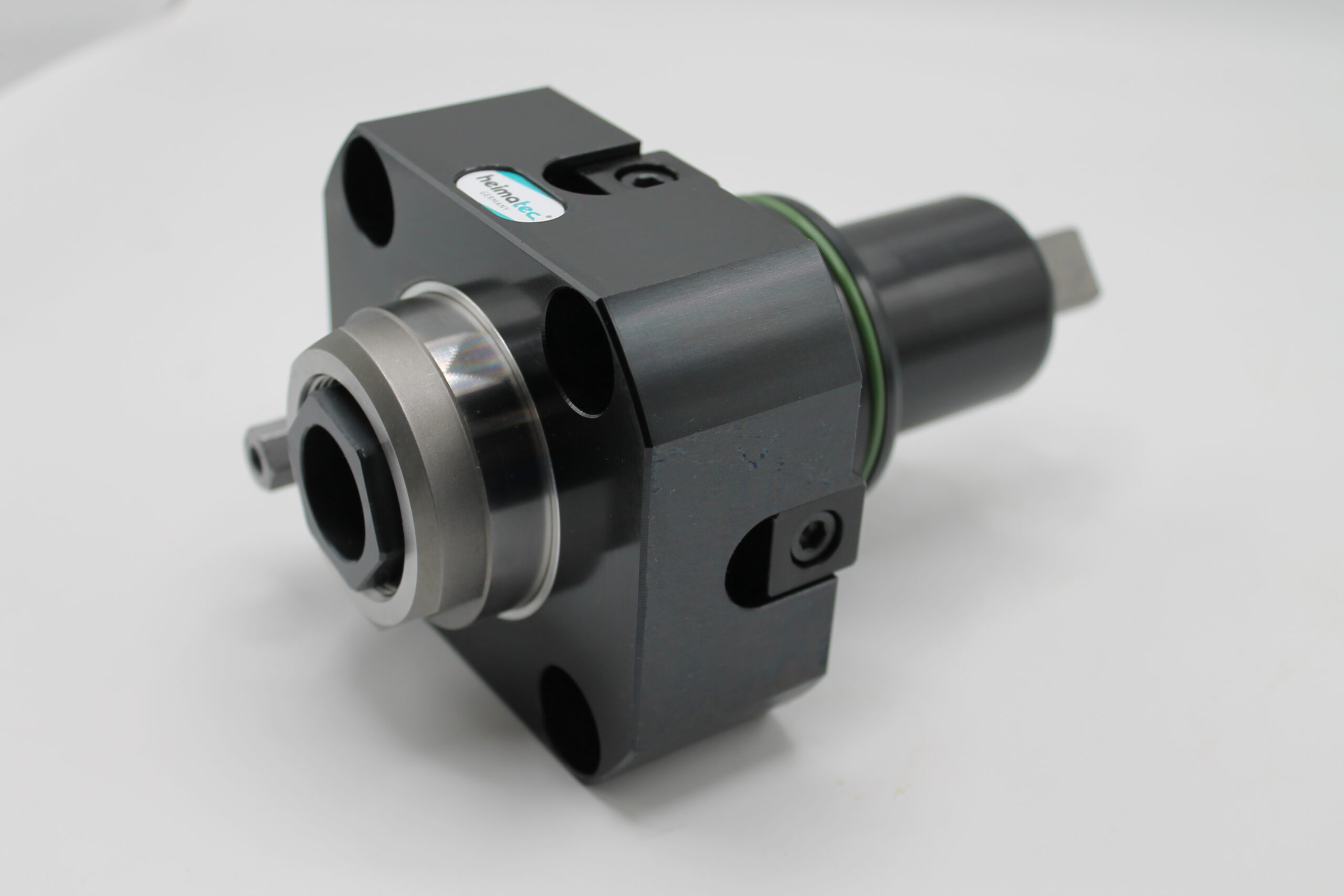

Platinum Tooling Technologies Inc. has unveiled the Haas multitool, a new quick-change tooling system designed to significantly improve productivity and operational efficiency for CNC lathe users. This innovative system focuses on reducing setup times and enhancing overall machine utilization—two critical factors that directly impact shop floor performance and profitability.

In traditional CNC turning operations, tool changes can be time-intensive, often requiring manual adjustments that disrupt workflow and reduce machine uptime. The Haas multitool effectively addresses this challenge by enabling rapid, precise tool changes without the need for extensive recalibration. This allows machinists to switch tools quickly and maintain production continuity, minimizing downtime between jobs.

Engineered for broad compatibility, the Haas multitool integrates seamlessly with a variety of Haas CNC lathes, offering flexibility across multiple machine types. It supports several tool configurations, empowering operators to handle different machining tasks using the same setup. This versatility helps manufacturers simplify tooling management while maintaining consistent accuracy and repeatability.

The system’s compact and durable design makes it easy to integrate into existing production setups. Built to withstand high spindle speeds and demanding cutting conditions, it ensures stable and reliable performance even in high-output manufacturing environments. The robust construction also helps extend tool life and maintain consistent precision, reducing the frequency of tool changes and maintenance.

One of the standout features of the Haas multitool is its enhanced tool positioning accuracy, which directly contributes to improved part quality. By minimizing manual errors and ensuring consistent tool alignment, the system helps manufacturers achieve superior surface finishes and tighter tolerances, meeting the increasing quality demands of modern machining applications.

For shops striving to boost efficiency and streamline workflows, the Haas multitool offers a practical and cost-effective solution. It not only saves time but also reduces operator fatigue and complexity, allowing teams to focus more on production and less on setup. This makes it ideal for both high-mix, low-volume operations and continuous high-volume manufacturing.

Platinum Tooling’s introduction of the Haas multitool reinforces its commitment to providing innovative tooling solutions that empower manufacturers to get the most out of their CNC machines. By combining quick-change convenience with robust engineering, the system enables users to achieve faster turnarounds, higher machine utilization, and consistent machining quality—key advantages in today’s competitive manufacturing landscape.