Open Mind Software Enhances Five-Axis Programming Efficiency with HyperMill 2025!

By Ashutosh Arora

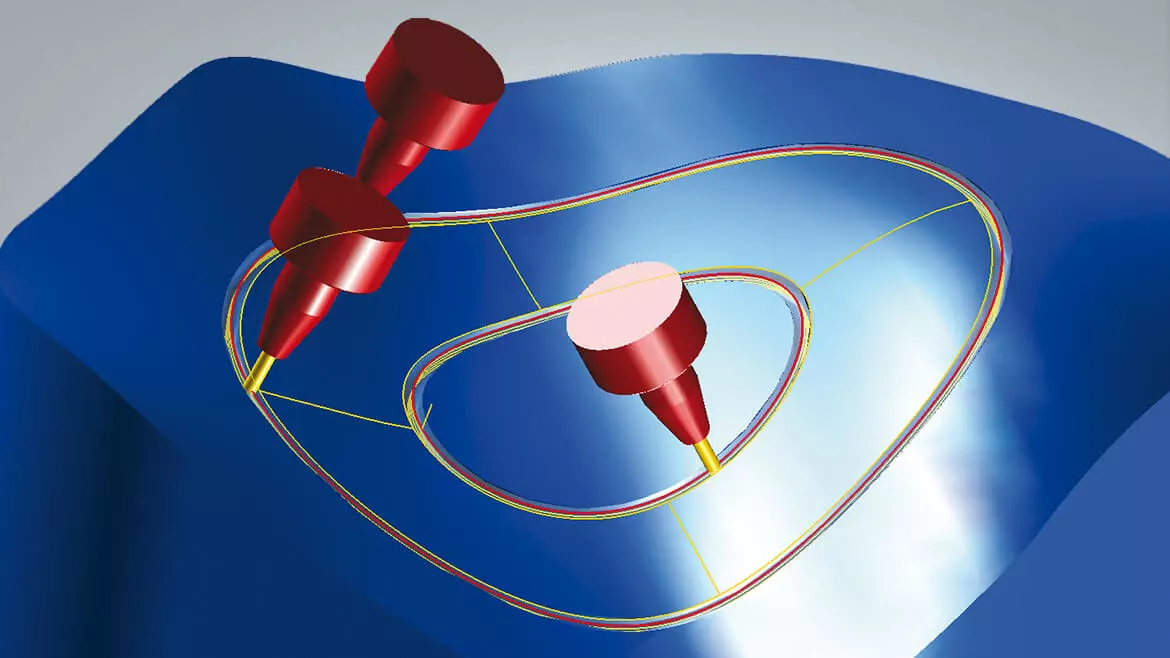

At Eastec 2025, Open Mind Technologies showcased the HyperMill 2025 CAD/CAM software, introducing a five-axis automatic tool orientation mode that is set to streamline the programming of complex components. This innovative feature aims to simplify five-axis machining by reducing the number of manual inputs required and accelerating the programming process. The five-axis automatic tool orientation mode algorithm analyzes the entire toolpath in advance to calculate the machining sequences for simultaneous and indexed tool movements, offering increased reliability and efficiency.

HyperMill 2025 offers a range of enhancements designed to tackle the challenges of machining intricate parts. One of the standout additions is the five-axis hole deburring strategy, which provides a solution for deburring sharp edges on holes and intersecting holes. Using CAM Plan programming assistance and analysis technology, HyperMill can automatically identify all holes in a model and mark the sharp edges for easy selection. This advanced technology supports both three-axis and five-axis machining options, providing greater flexibility in handling complex deburring tasks.

Another key feature is the enhanced pocket milling algorithm, which has been redeveloped for 3D-optimized roughing with high feed cutters. This update significantly improves the efficiency and control during the roughing phase, particularly when dealing with large lateral in-feeds and remaining material. The improved algorithm helps manufacturers achieve better machining control and more consistent results during the roughing stage of production.

Additionally, contour and path radii can now be defined more effectively, resulting in better-rounded tool paths, which further enhance machining performance. This, in turn, minimizes the time and effort required to achieve the desired finish, allowing for smoother, more accurate operations.

HyperMill Virtual Machining Optimizer has been further enhanced with Dynamic Stock technology, which optimizes linking movements based on the actual stock conditions. By automatically updating stock information for each machining job, Dynamic Stock ensures that linking movements are calculated with precision, resulting in more accurate and efficient toolpaths.

This real-time update feature ensures that all stock conditions are accounted for throughout the machining process, preventing errors and ensuring a smooth flow of operations. The integration of Dynamic Stock enables manufacturers to achieve higher accuracy and improve their overall machining efficiency.

The advancements in HyperMill 2025 are particularly beneficial for manufacturers working with complex five-axis components. By automating many of the tool orientation decisions and incorporating dynamic stock updates, the software reduces the need for manual programming and increases overall productivity. The five-axis hole deburring and optimized roughing strategies are examples of how HyperMill 2025 provides faster, more reliable toolpaths, which is crucial for industries that require precision and high-speed machining.

By integrating these advanced features, Open Mind Technologies is positioning HyperMill 2025 as an essential tool for improving productivity in the five-axis machining space, making it easier for manufacturers to handle complex tasks, reduce production time, and ensure higher-quality finishes across a range of industries.