NTA Introduces Energy-Efficient Pneumatic Valves to Cut Power Use in High-Speed Automation!

Ningbo Titan Industrial Automation Co., Ltd. (NTA) has unveiled a new generation of energy-saving pneumatic valves aimed at helping manufacturers reduce compressed air and electricity consumption without compromising the speed and reliability demanded by modern automated production lines. The launch comes at a time when manufacturers across industries are under increasing pressure to lower operating costs, meet tighter environmental regulations, and improve overall energy efficiency while keeping productivity high.

Rather than pursuing expensive and disruptive overhauls of entire automation systems, many factories are now targeting efficiency improvements at the component level. Pneumatic valves, which are widely used across assembly, packaging, and material handling applications, have long been a source of hidden energy losses. Conventional valve designs often suffer from air leakage and high power draw, especially in high-frequency switching environments where even small inefficiencies are magnified over continuous operation.

NTA’s newly launched valves address these issues through a redesign of internal airflow paths combined with the use of low-power electromagnetic coils. By optimizing how air moves through the valve and reducing electrical losses in actuation, the company has been able to significantly cut wasted energy. According to NTA, the new design can deliver energy savings of up to 30 percent compared with traditional pneumatic valves, depending on duty cycle and operating conditions. For manufacturers running high-volume or around-the-clock operations, this level of efficiency improvement can translate into meaningful reductions in operating expenditure over the life of the equipment.

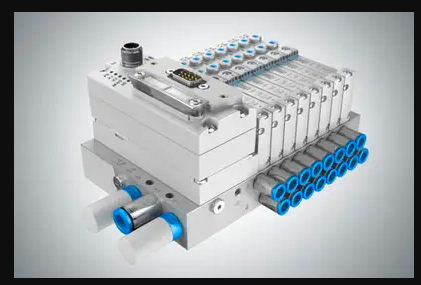

Crucially, the focus on energy efficiency has not come at the expense of performance. The valves are engineered to support high-speed switching with stable and repeatable operation, making them suitable for demanding automation tasks such as fast assembly lines, robotic handling systems, and packaging machinery. Their compact design allows easier installation in densely packed control cabinets, while also simplifying maintenance and replacement in production environments where downtime must be minimized.

To support global automation requirements, the valves are compatible with major industrial communication protocols, including Profinet, EtherCAT, EtherNet/IP, and CC-Link IE Field Basic. This interoperability enables straightforward integration into existing control architectures and makes the valves suitable for international OEM projects where standardization and flexibility are essential. Designed for harsh industrial conditions, the valves are capable of operating at switching frequencies of up to 40 Hz and temperatures as low as –40°C, while maintaining reliable performance in environments exposed to moisture, dust, and debris. Typical application areas include packaging machinery, medical and laboratory equipment, vehicle systems, and a wide range of general industrial automation uses.

NTA currently serves customers in more than 100 countries and operates under ISO 9001:2015 and IATF 16949:2016 quality management certifications, with products compliant with CE and RoHS standards. To support growing global demand, the company is also investing in capacity expansion and is developing a 90,000-square-meter intelligent manufacturing facility that is scheduled to begin operations in 2026. This facility is expected to further strengthen NTA’s ability to deliver high-volume, consistent, and technologically advanced automation components.

Commenting on the launch, Zhu Sijie, founder of NTA, noted that energy efficiency and rapid response have become baseline expectations rather than optional features in today’s automation systems. He emphasized that NTA’s approach is centered on delivering practical, immediately deployable improvements that engineers can adopt without redesigning entire production lines. With rising energy costs and sustainability targets shaping manufacturing decisions worldwide, NTA’s new pneumatic valves are positioned as a timely solution for factories looking to improve efficiency while maintaining high-speed automation performance.