Norelem Introduces New Compact Floating Clamps for Secure Clamping of Delicate Workpieces!

By Ashutosh Arora

Norelem Inc. has launched a new range of floating clamps designed to provide secure clamping and support for components with overdetermined clamping points. These new clamps expand the company’s existing product range, offering a flexible solution for handling delicate and sensitive workpieces during machining. The introduction of these compact floating clamps is particularly beneficial for applications involving thin-walled components that are prone to bending or deflection. By providing a controlled amount of flexibility, the clamps can secure the workpieces without compromising precision, making them ideal for industries that demand high accuracy and minimal clamping errors.

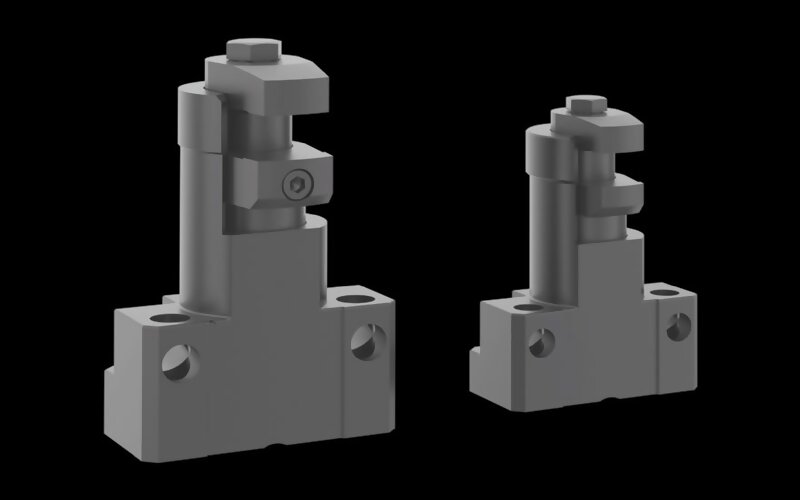

The new floating clamps are available in two versions: Form A and Form B. Form A features fixed clamping jaws, designed for applications where a steady, unchanging clamping solution is required. On the other hand, Form B allows for the adjustment of the clamping jaws, offering flexibility to cater to different workpiece shapes and sizes. This added versatility makes Form B ideal for users who require a more adaptable clamping system for varying applications.

Designed to handle high clamping forces, the new floating clamps from Norelem offer impressive capabilities, with Form A achieving forces up to 5000 N and Form B capable of reaching up to 8000 N. Both versions are constructed from nitrocarburized steel for the base body, ensuring durability and resistance to wear and tear, while the end stops are made of black anodized aluminum for enhanced performance in demanding environments. The clamps’ robust design allows them to perform reliably even under high-pressure conditions.

One of the key features of these floating clamps is their ability to hold workpieces securely while allowing for a degree of motion. This “floating” fixation prevents vibrations and deflections during machining, which is critical when working with parts that have irregular shapes or delicate features. The flexibility provided by the floating mechanism ensures that the clamps offer precision without damaging the components. By eliminating clamping errors and stabilizing the workpiece, the clamps improve overall machining results, making them particularly well-suited for industries such as aerospace, automotive, and general engineering.

The operation of the floating clamp system is straightforward and easy to use. In the first step, the clamp is pressed downward to position it under the workpiece. Then, the jaws are swiveled into place, with the lower jaw securely contacting the bottom of the workpiece. The position is then fixed by tightening a hexagon nut to the specified torque, ensuring that the workpiece is both clamped and supported. This simple yet effective system provides excellent control over the workpiece, reducing the chances of movement or errors during the machining process.

Norelem’s new floating clamps provide a high-performance, flexible clamping solution for manufacturers working with sensitive or complex workpieces. Their combination of sturdy construction, adjustable features, and ease of use makes them an essential tool in modern production environments where precision and efficiency are crucial. Whether used in aerospace, automotive, or other high-precision industries, these clamps offer the reliability and adaptability needed to ensure high-quality results and improved productivity.