Net Solution for AI-Based Image Evaluation Revolutionizes Performance and Zero-Defect Production

Scandinavian Manufacturing Company Implements Cutting-Edge AI Technology for Enhanced Production Efficiency

A pioneering AI-based image evaluation system is setting new benchmarks in performance, zero-defect production, and speed, significantly transforming the manufacturing landscape for a leading Scandinavian company. This state-of-the-art solution, pivotal for the production of around 1.2 million indexable inserts weekly, guarantees unparalleled process reliability and productivity in industries such as metalworking, automotive, and aerospace.

Application and Impact

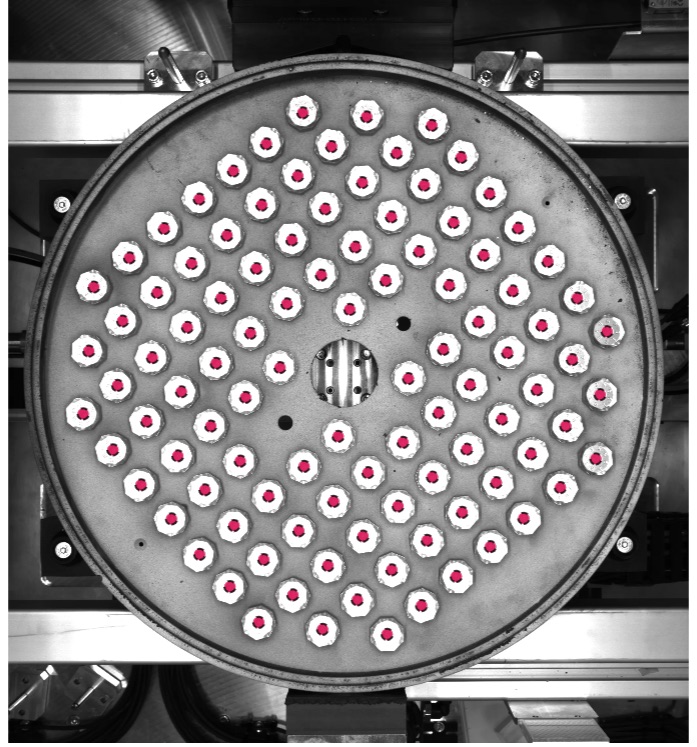

Each week, the Scandinavian company’s production facilities generate approximately 1.2 million indexable inserts, essential for ensuring high process reliability and productivity across various industries. These inserts, produced through a meticulous sintering process involving powdered metals and hard materials, are designed to achieve optimal cutting and wear resistance. Following the sintering process, these inserts undergo edge rounding, surface blasting, grinding, and coating.

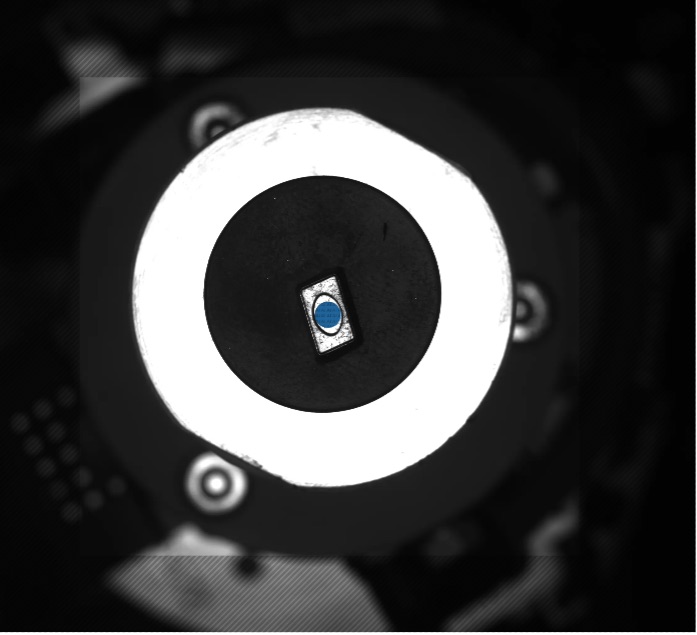

Directly following the sintering process, the Robotvision system from Swabian engineers plays a critical role. Marvin Krebs, Director of Technical Sales at Xactools, explains, “Detecting defects early in the process makes it easier and cheaper to rectify them.” The system employs eight high-resolution industrial cameras and two spider robots to meticulously inspect the inserts for defects, ensuring high standards of quality.

At the heart of this advanced image processing system lies DENKnet’s AI, seamlessly integrating with cameras, robots, and a multi-GPU computing rack.

Challenges and Solutions

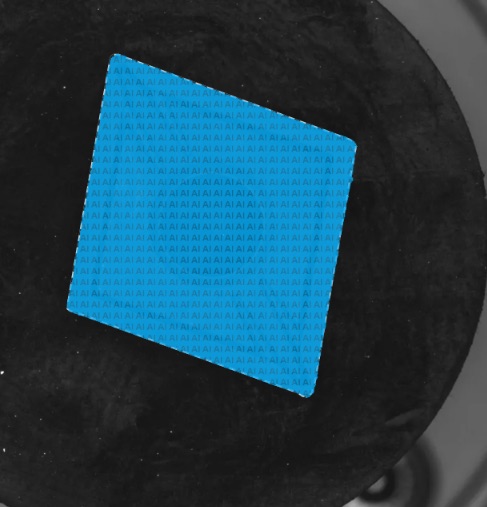

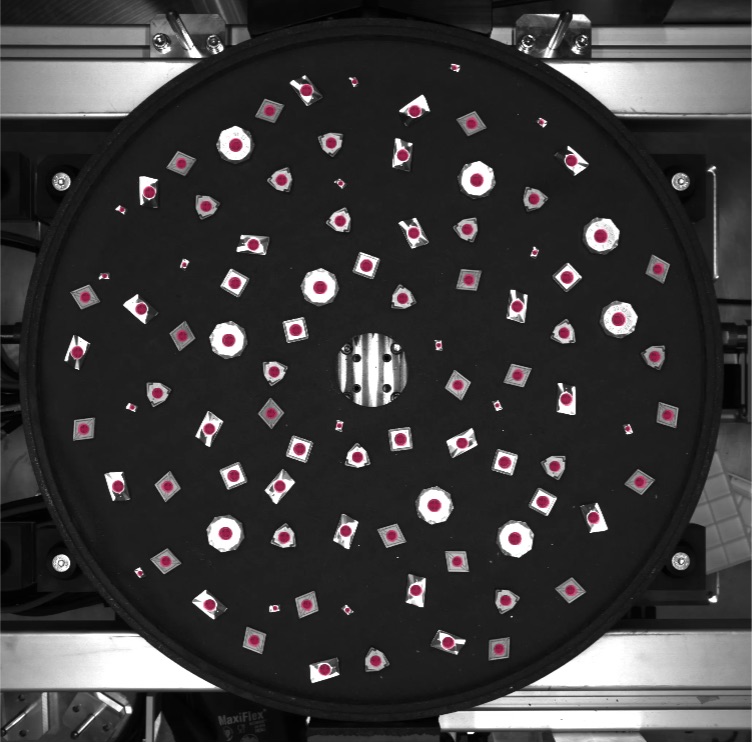

The vast array of small tool parts, with around 2,800 products categorized into nearly one hundred geometry families, posed a significant challenge for automated handling and defect inspection. “Variations in color and gloss levels during the pressing process are not defects,” explains Krebs. The AI-based image evaluation software had to be extensively trained to differentiate between acceptable color deviations and actual defects like cracks, scratches, and inclusions.

The AI’s proficiency extends beyond visual inspection to geometric categorization, efficiently managing the diverse shapes and sizes of the inserts. Xactools defined almost one hundred geometry families, and training the AI required just 20 to 30 images per family. The DENKnet palletizing AI, supported by the DENK VISION AI Hub, delivered reliable results from the outset, identifying and sorting defective inserts with over 99% accuracy.

Operational Excellence

The inspection system features eight cameras with resolutions ranging from 5 to 30 megapixels, capturing live images of the inserts. High-intensity illumination ensures precise defect detection, down to thousandths of a millimeter. The system also captures images of the insert’s contour and position, enabling accurate placement by magnetic grippers on pin pallets.

Marvin Krebs highlights the system’s efficiency, “The self-learning AI now recognizes new parts without additional training, ensuring consistent quality control.”

AI-Driven Advancements

The integration of DENKnet’s AI significantly enhances defect detection and part family creation, which would be unfeasible with conventional methods. The flexibility and high performance of the DENKnet software, coupled with seamless API integration, have streamlined the inspection process. The entire cycle, from inspection to sorting, is completed in just four seconds with nearly 100% picking efficiency.

Future Prospects

The success of this AI-driven inspection system opens avenues for broader applications. The DENKnet training environment, accessible without programming knowledge, enables swift and automated AI training. “Over 95% of our measuring and testing systems now incorporate at least one AI object class,” notes Krebs, emphasizing the expanding potential of AI in manufacturing.

As industries strive for higher standards of precision and efficiency, this advanced AI solution represents a significant leap forward, promising continued innovation and excellence in automated production processes.