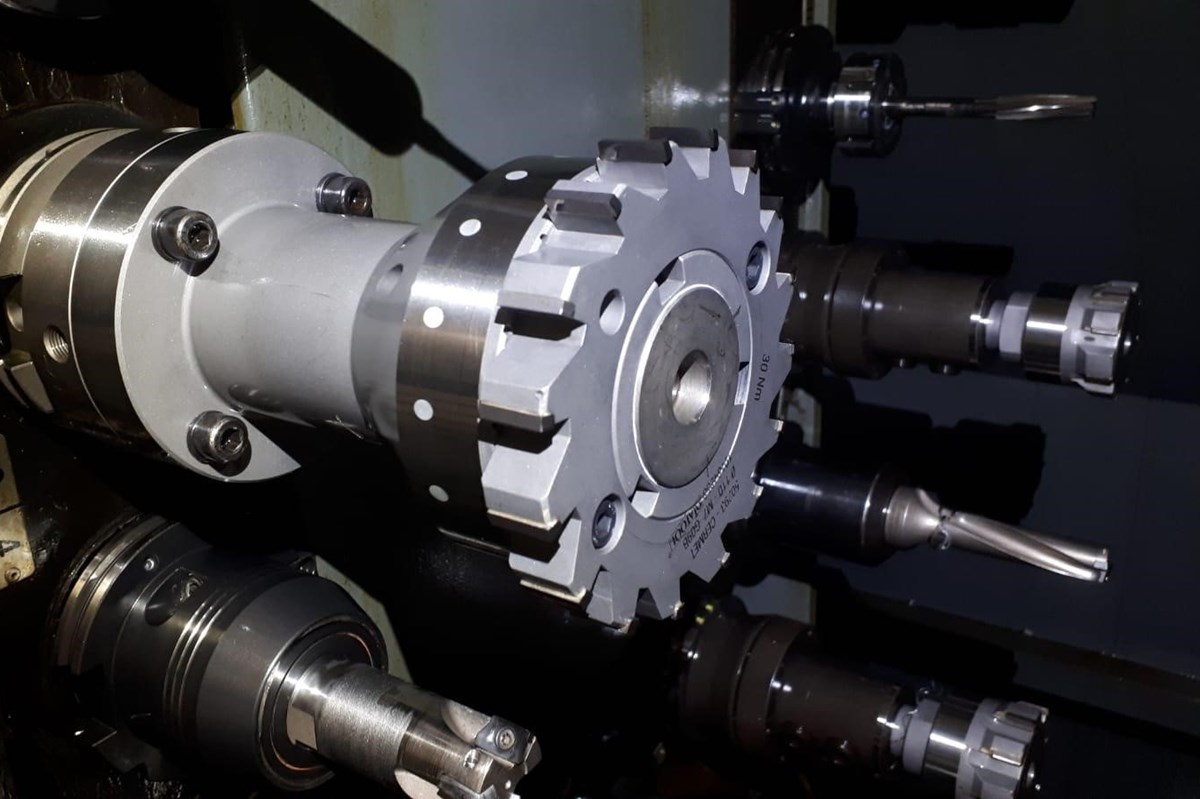

Monaghan Tooling’s Diatool Reamer: Faster, More Precise Boring with Fewer Tool Changes!

By Ashutosh Arora

Monaghan Tooling Group’s Diatool reaming technology is revolutionizing precision holemaking with its custom, three-step monoblock reamer. Designed to eliminate multiple tool changes, this innovative solution improves cycle times, accuracy, and efficiency in high-precision machining applications.

Traditional reaming operations often require multiple tools and frequent tool changes, leading to longer cycle times and increased setup complexity. Diatool’s monoblock reamer combines multiple reamers into a single tool, eliminating two tool changes and significantly boosting productivity.

Key advantages include:

- Unevenly spaced cutting edges for highly cylindrical and round bores, ensuring superior accuracy at higher feed rates.

- Enhanced chip evacuation to prevent stringy chip buildup, reducing downtime and minimizing part damage.

- No dial-in adjustments required, simplifying operation and lowering the risk of scrap parts.

Diatool’s custom three-step reamers deliver measurable cost savings and improved quality in automotive, aerospace, medical, and general machining applications. Compatible with a wide range of materials, including aluminum, steel, cast iron, and nonferrous alloys, these reamers provide superior surface finishes and repeatability compared to single-point tools.

By integrating advanced reaming technology into a single, streamlined tool, Monaghan Tooling’s Diatool solution optimizes machining efficiency, reduces tooling costs, and enhances precision—making it a game-changer for manufacturers seeking higher productivity and superior bore quality.