ModuleWorks 2025.12 Software Release Strengthens Machining Simulation, Process Control and CAM Flexibility!

ModuleWorks GmbH has announced the release of ModuleWorks 2025.12, introducing a broad set of enhancements aimed at improving machining simulation accuracy, toolpath control, and programming efficiency across a wide range of CAM applications. The latest update focuses on three-axis machining, feed control optimization, adaptive roughing, deburring, and swarf machining, reinforcing ModuleWorks’ role as a core technology provider for advanced CAD/CAM systems.

A key improvement in the 2025.12 release is the introduction of a corner finishing option for three-axis machining, particularly relevant for mold and die applications. Building on existing multi-pencil and rest-finishing strategies, this new capability enables safer and more reliable material removal in inner corners, which are often challenging due to tool accessibility and remaining stock detection. The enhanced logic improves rest-area identification and allows steep and shallow regions of a part to be processed independently. This adaptability enables CAM systems to handle more complex part geometries while maintaining surface quality and reducing the risk of tool overload.

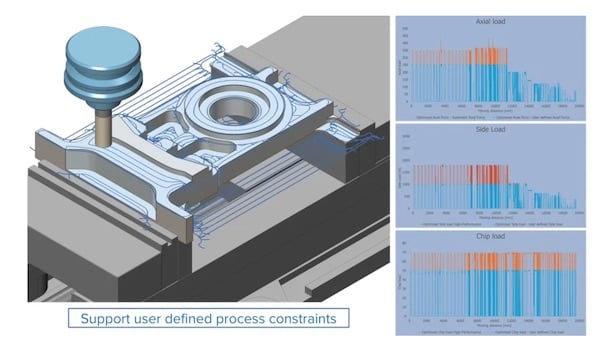

Feed control functionality has also been significantly expanded. In the new release, feed control toolpaths can be fine-tuned using parameters such as side load, chip load, and power or torque limits. This allows experienced users to define custom machining constraints directly within the feed control interface, rather than relying on fixed or generalized cutting parameters. By dynamically adapting feed rates to cutting forces and machine capabilities, manufacturers can achieve more stable machining conditions, reduce tool wear, and optimize cycle times, particularly in demanding or non-standard cutting scenarios.

Another notable addition is minimum stock wall thickness control, designed to prevent the unintended creation of thin residual walls during machining. Thin walls can lead to vibration, stock deflection, and tool breakage, especially during finishing operations. The new feature automatically avoids toolpaths that would generate such conditions, helping to protect both the tool and the workpiece. By maintaining part integrity throughout the machining process, this enhancement contributes to longer tool life, improved surface finish, and greater overall process reliability.

Deburring operations have also been streamlined in ModuleWorks 2025.12. Traditionally, deburring top and bottom edges required separate tools and multiple operations, increasing both programming time and machining complexity. With the updated support for double chamfer tools, both upper and lower edges can now be deburred in a single operation. The system automatically selects the appropriate chamfer for each contour, significantly reducing programming effort while improving consistency and efficiency on the shop floor.

The release also delivers a major improvement in swarf machining, an area that often requires complex surface analysis and guide curve definition. The enhanced algorithm in ModuleWorks 2025.12 can reliably detect suitable guide curves even on surfaces with rounded corners. This enables more accurate toolpath generation and consistent machining results across complex geometries. As a result, programming workflows become faster, more robust, and more adaptable to diverse part designs.

Overall, the ModuleWorks 2025.12 update reflects a continued focus on giving CAM developers and end users greater control, stability, and efficiency in machining operations. By combining smarter algorithms with deeper process control, the release helps manufacturers improve productivity, reduce risk, and achieve higher-quality results in increasingly complex manufacturing environments.