Meltio Marks 2025 as a Turning Point for Wire-Laser Directed Energy Deposition in Industrial Production!

Meltio has confirmed 2025 as a decisive year for the industrial adoption of wire-laser Directed Energy Deposition (DED), marking a clear shift of metal additive manufacturing from controlled pilots to full-scale industrial production. Across multiple sectors, manufacturers have demonstrated measurable gains in productivity, cost efficiency, and supply chain resilience by deploying Meltio’s wire-based metal AM systems directly on the shop floor.

Throughout the year, Meltio strengthened its industrial footprint by engaging with manufacturers at major global trade exhibitions such as MilAM, Rapid + TCT, EMO Hannover, and Formnext. These platforms enabled the company to move beyond theoretical capability discussions and instead present validated production data, real components, and proven use cases to industries including automotive, defence, mining, naval, oil & gas, and heavy engineering.

One of the most significant milestones in 2025 was the opening of Meltio’s first international reference site in Danville, Virginia, in collaboration with Fastech. Designed as a hands-on industrial environment, the facility allows customers to see Meltio systems operating under real production conditions, including the Meltio M600 metal 3D printer and the Meltio Robot Cell. The site also supports localized manufacturing strategies, helping customers shorten lead times and reduce dependence on long, fragile supply chains.

Defence applications emerged as a key growth area during the year, reflecting increasing demand for on-demand metal manufacturing and repair in operational environments. Meltio showcased real deployments with organisations such as the U.S. Navy and the Republic of Korea Marine Corps, including a case where a critical reverse osmosis pump aboard a naval vessel was restored in just 34 hours. This dramatically outperformed traditional procurement timelines and highlighted the strategic value of near-site and onboard manufacturing.

In parallel, Meltio continued to gain traction in high-volume and cost-sensitive industrial sectors. Case studies presented during EMO Hannover and Formnext showed how wire-laser DED can reduce material waste, shorten production cycles, and deliver stronger ROI compared with conventional forging, casting, or extensive machining. These results have accelerated adoption for functional parts, tooling, and repair applications, particularly within automotive and heavy industry.

A recurring theme throughout 2025 was supply chain resilience. For industries such as oil and gas, where unplanned downtime can be extremely costly, Meltio demonstrated how on-demand production and repair can compress lead times from months to days. By enabling components to be manufactured or restored close to the point of use, Meltio’s technology offers manufacturers greater autonomy and operational security.

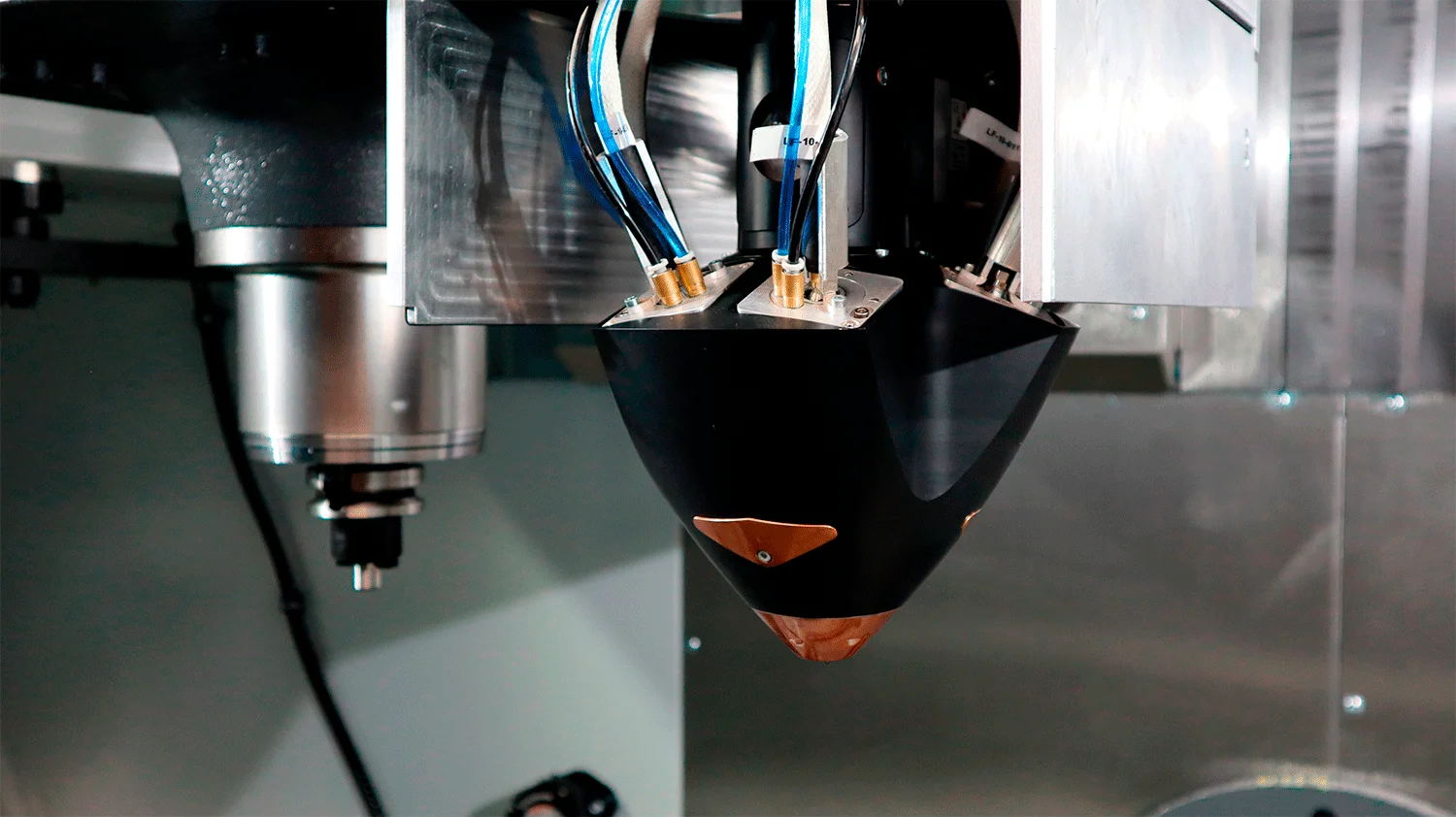

Central to these advances was the rollout of the Meltio Engine Blue, equipped with a 1.4 kW blue laser optimised for processing reflective materials such as copper and aluminium. Compared with traditional infrared laser systems, the technology delivers faster deposition rates, improved energy efficiency, and an expanded material portfolio. Demonstrations in 2025 included multi-material components for defence, naval, and industrial applications, underlining the platform’s production-ready versatility.

From a business standpoint, 2025 also marked a period of global expansion for Meltio, driven by rising demand for practical, scalable metal additive manufacturing solutions. Deployments across automotive, defence, aerospace, mining, and energy sectors reinforced Meltio’s position as a provider of industrial production systems rather than experimental tools.

Looking ahead, Meltio enters 2026 with a growing portfolio of validated applications and a clear focus on enabling manufacturers to achieve greater independence, resilience, and efficiency through wire-laser metal additive manufacturing.