Mate Precision Technologies Introduces Machinable Hard Jaws for Complex Geometries!

By Ashutosh Arora

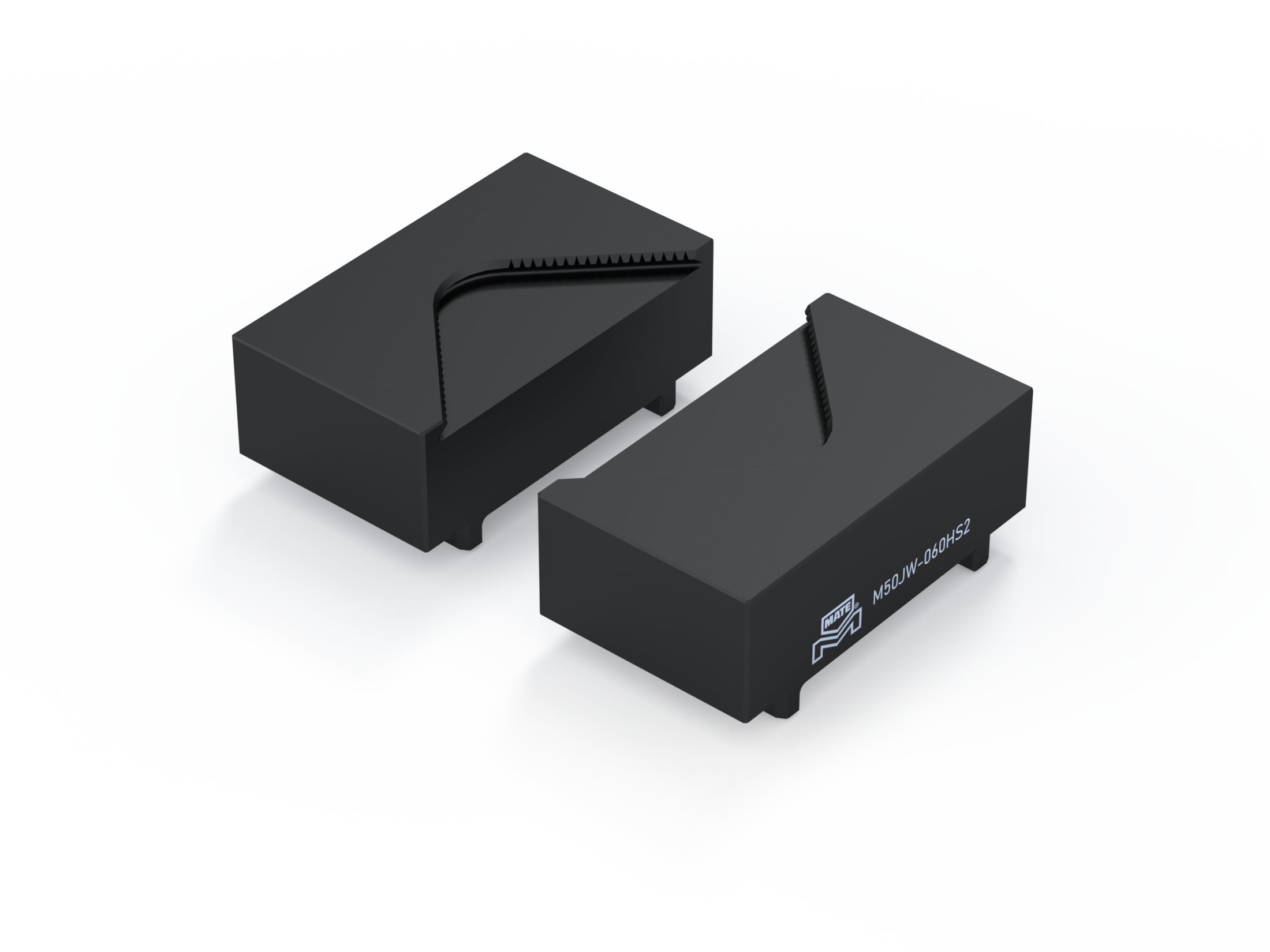

At the PMTS 2025 event, Mate Precision Technologies introduced their innovative machinable hard jaws, which offer a versatile solution for securely holding complex part geometries during critical finishing operations. These custom jaws are specifically designed to be compatible with all sizes of Mate’s DynoGrip workholding vises, making them a valuable tool for high-precision tasks. By offering increased rigidity and precision, they help manufacturers handle parts that would typically require soft jaws but with the added benefits of greater stability and strength.

One of the standout features of these machinable hard jaws is their adaptability. The jaws are available in two configurations: center and movable, allowing them to accommodate a wide variety of parts, regardless of shape or complexity. The jaws also feature Mate’s proprietary quick-change design, which greatly enhances workflow efficiency. This design allows operators to change out the jaws with minimal downtime, further increasing productivity in high-demand machining environments.

In addition to their robust design, these machinable jaws come in a blank form, offering customers the flexibility to add a custom profile that meets their unique workholding needs. Whether customers prefer to make these modifications themselves or would like Mate Precision Technologies to customize the jaws before shipping, they have the freedom to create tailored solutions. The machinable hard jaws are constructed from the same hardened tool steel used in Mate’s standard jaws, providing a core hardness of 45-50 HRC and surface hardness up to 65 HRC. This superior material hardness ensures the jaws are tough and durable, enabling them to handle intricate and demanding geometries typically reserved for soft jaws, but with the added benefit of improved rigidity.

The customizability of these jaws is one of their key advantages. Mate Precision Technologies offers a variety of modification options to accommodate special geometries and unique part shapes. For instance, they can modify the jaws to hold custom dovetails or Picatinny rail dovetails, which are commonly used in military, aerospace, and defense industries. In addition, the jaws can be designed for clamping round parts, or even V-shaped jaws with teeth for enhanced grip. Furthermore, these jaws can come with inserts designed for clamping bars on top of the jaws, expanding their versatility in different applications.

These machinable hard jaws are particularly beneficial for holding complex part geometries during finishing operations, where precision and stability are paramount. Their adaptability and robust design make them an essential tool for industries such as aerospace, automotive, medical device manufacturing, and any other field where high-precision part production is necessary. The jaws’ ability to maintain part integrity while providing a high level of rigidity during machining processes makes them a critical component for manufacturers looking to improve quality and reduce production time.

Overall, Mate Precision Technologies’ machinable hard jaws stand out as an ideal solution for manufacturers dealing with parts that require complex workholding solutions. By offering customization options, superior rigidity, and ease of use, these jaws help manufacturers achieve tighter tolerances and enhance the quality of their finished products. Whether used in high-volume production or precision jobs, these workholding jaws contribute significantly to the efficiency and effectiveness of modern manufacturing processes.