MAPAL Expands NeoMill Milling Program for High-Efficiency Semi-Finishing and Finishing Operations!

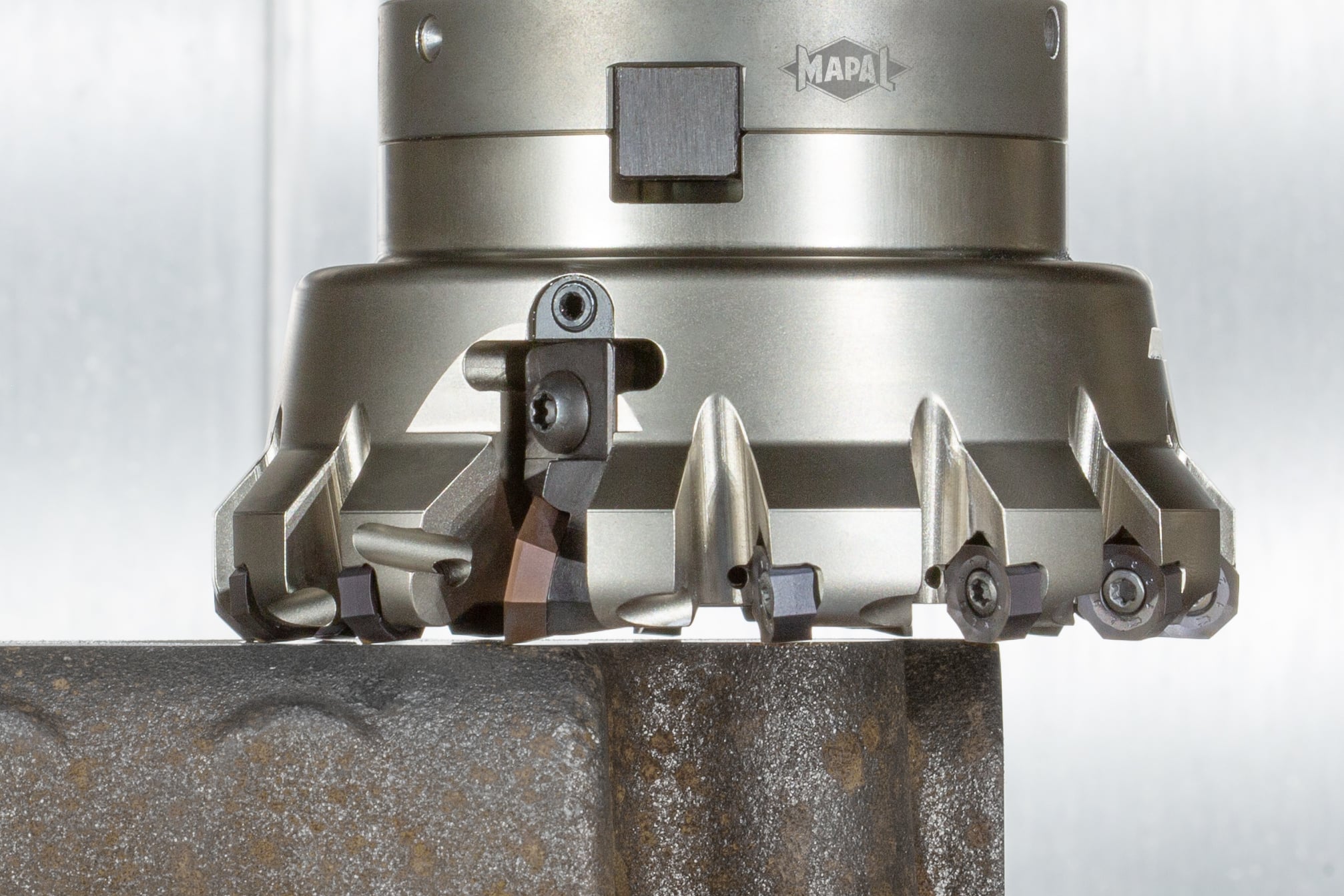

MAPAL has expanded its NeoMill milling program with the introduction of three new cutter series developed specifically for the demands of series production, strengthening its offering for semi-finishing, finishing, and high-performance roughing applications. The new additions—NeoMill-16-Finish, NeoMill-16-Face, and NeoMill-Alu-Rough—are designed to deliver high efficiency, consistent process reliability, and sustainable manufacturing performance, while integrating seamlessly into MAPAL’s existing milling portfolio.

The expansion addresses the growing need in modern manufacturing for tools that can deliver both productivity and precision across large production volumes. By optimizing cutting edge utilization, tool stability, and chip evacuation, the new NeoMill solutions aim to reduce machining costs per component while maintaining high and repeatable quality. All three series are engineered to support stable cutting conditions and long tool life, making them particularly suitable for automated and high-throughput production environments.

The NeoMill-16-Finish has been developed for applications where demanding surface finish and dimensional accuracy are essential. Its design combines a 16-edged roughing insert with an eight-edged finishing insert within a single face mill, allowing efficient material removal followed by controlled finishing in the same tool concept. This approach helps minimize tool changes and setup complexity while enabling manufacturers to achieve fine surface qualities, with finishes reaching as low as Rz 4 µm. Available in standard diameters from 63 to 200 mm, the tool also allows easy and precise adjustment of the finishing cutting edges, providing flexibility to fine-tune surface quality in series production.

Complementing this is the NeoMill-16-Face, which has been developed to enhance MAPAL’s pre-machining and semi-finishing capabilities. Using the same 16-edged indexable insert, this face mill focuses on cost efficiency and stable machining performance. The high number of usable cutting edges significantly reduces tooling costs per part, while the robust insert design ensures consistent results even under demanding production conditions. With diameters ranging from 32 to 125 mm, the NeoMill-16-Face is particularly suited for the series production of cast and steel components with small machining allowances, down to 2 mm, which are common in near-net-shape manufacturing processes.

For aluminum machining, MAPAL has introduced the NeoMill-Alu-Rough series, offering a high-performance solution for roughing aluminum castings in automotive, aerospace, and mechanical engineering applications. The series includes corner milling cutters and end mills designed for high material removal rates and stable cutting behavior. Standard single-row milling cutters are available in diameters from 50 to 160 mm, while multi-row end mills are offered in selected sizes, with the option for custom tooling configurations. The combination of large chip spaces, tangentially mounted indexable inserts, and a wide choice of cutting materials—including PCD, coated or uncoated carbide, and CVD diamond—ensures reliable chip evacuation and high process stability, even when machining large chip volumes.

With this expansion of the NeoMill program, MAPAL reinforces its focus on efficient, reliable, and sustainable machining solutions for series production. By addressing semi-finishing, finishing, and roughing requirements with a unified tool platform, the company enables manufacturers to improve productivity, reduce tooling costs, and maintain consistently high component quality across a wide range of applications.