Lyndex-Nikken Introduces EZ-SmartTower for ROI Analysis and Machine Utilization Tracking!

Lyndex-Nikken has launched the EZ-SmartTower, a machine monitoring system designed to help manufacturers improve machine utilization and evaluate return on investment (ROI). The solution targets shops dealing with skilled labour shortages and rising operational costs, where accurate production data is critical for informed decision-making.

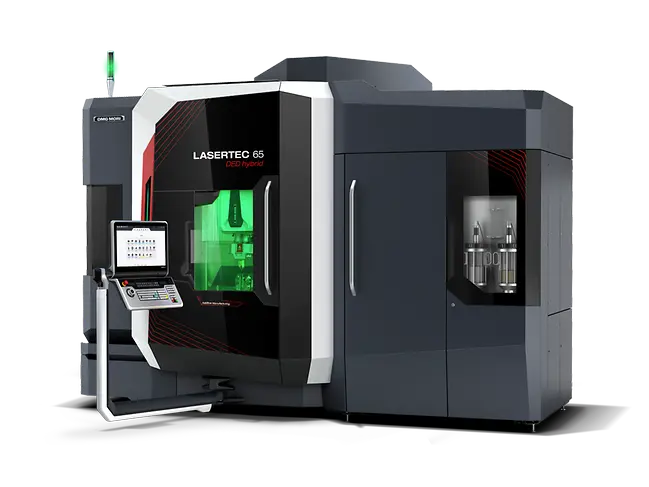

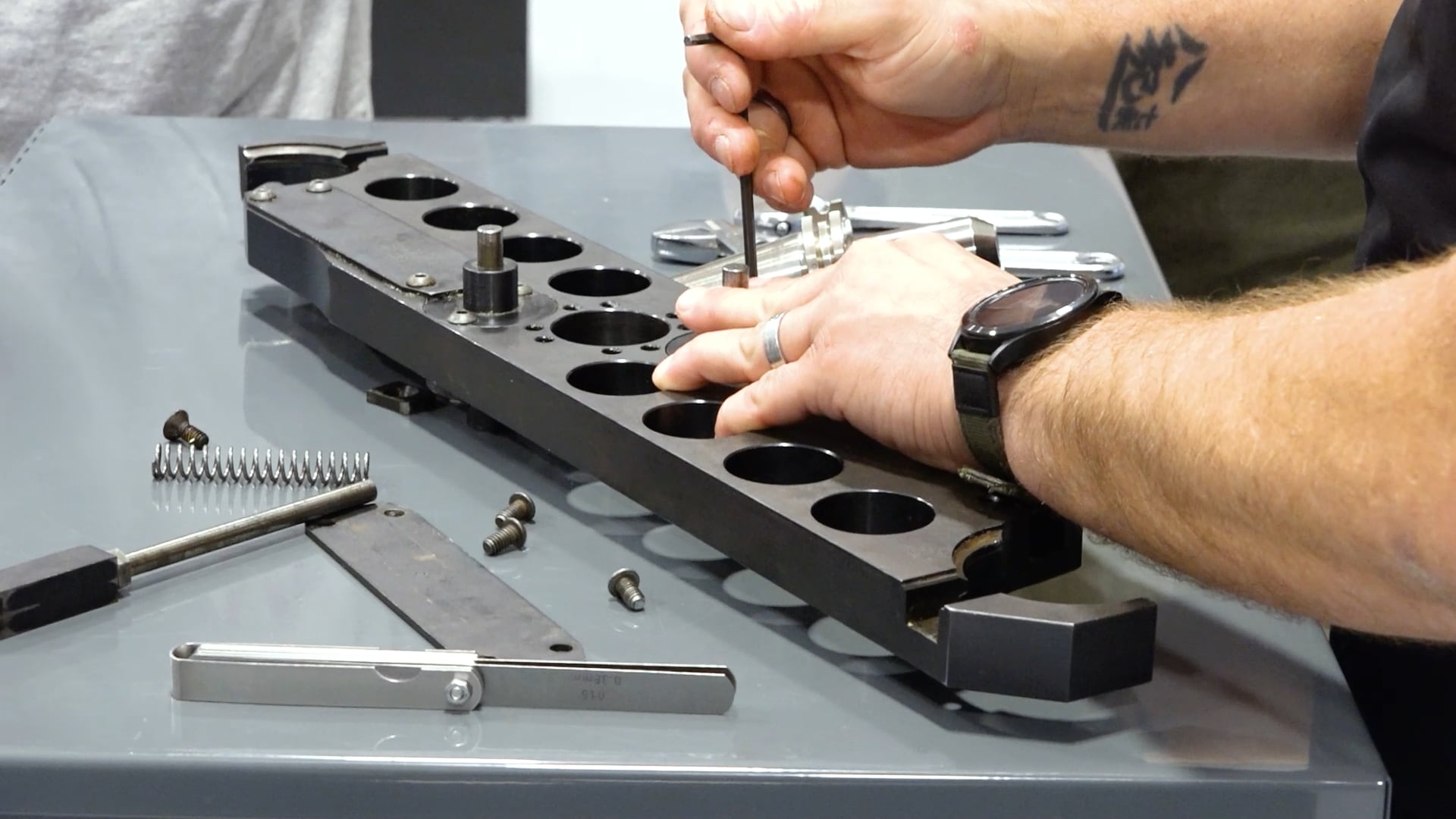

The EZ-SmartTower enables centralized monitoring of up to 30 machines through a single computer interface. Its modular and scalable architecture supports integration with CNC lathes, machining centers and other production equipment, allowing manufacturers to consolidate performance data across multiple assets.

The system captures key production metrics such as cycle counts, idle time, cycle time and error time. These data points support detailed spindle utilization tracking and broader performance analysis. In addition, the platform records operator, machine and part-specific data, enabling deeper insights into workflow efficiency and production trends.

Real-time LED indicators display machine status, clearly identifying whether equipment is in cycle, idle or experiencing downtime. WiFi connectivity allows immediate data transfer within the facility, giving operators and supervisors access to live performance information. This visibility helps identify bottlenecks, reduce idle time and improve scheduling efficiency.

The included software enables users to generate performance reports in chart or Excel formats, supporting ongoing analysis and trend tracking. Manufacturers can use this data to assess throughput, benchmark performance and support capital investment decisions. Importantly, all data is stored locally within the shop environment and is not transferred to or stored in the cloud, ensuring data control and security.

With real-time monitoring and historical performance tracking, the EZ-SmartTower is designed to reduce downtime, improve utilization rates and optimize overall production processes. By transforming machine data into actionable insights, Lyndex-Nikken’s monitoring solution supports more efficient operations and stronger returns on manufacturing investments.