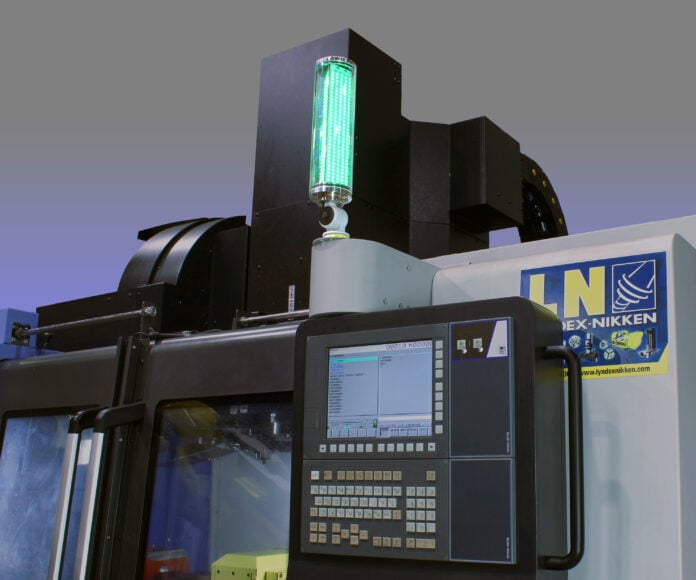

Lyndex-Nikken Introduces EZ-SmartTower for Real-Time Machine Tracking and ROI Analytics!

Lyndex-Nikken has introduced the EZ-SmartTower, a machine tracking and analytics solution designed to help machine shops improve efficiency and gain clearer insight into the return on investment (ROI) of their machine tools. The solution focuses on delivering real-time machine analytics in a simple and accessible format, enabling manufacturers to make informed, data-driven decisions without the need for specialized data science or IT expertise.

The EZ-SmartTower is engineered to provide a centralized view of shop-floor performance by allowing users to monitor and analyze production data from up to 30 machines simultaneously through a single computer. Its modular and scalable architecture enables easy integration with a wide range of equipment, including CNC lathes, machining centers, and other shop-floor machinery. This flexibility makes the system suitable for small job shops as well as larger production-oriented facilities looking to standardize performance tracking across multiple assets.

At the core of the system is its ability to capture and log critical machine data in real time. The EZ-SmartTower accurately records cycle counts, as well as idle time, cycle time, and error time, providing a detailed picture of spindle utilization and machine effectiveness. In addition, it captures operator, machine, and part-specific data, enabling more comprehensive performance analysis across shifts, jobs, and personnel. This level of visibility helps shops move beyond assumptions and anecdotal observations toward objective measurement of productivity.

Real-time monitoring is further enhanced through LED indicators that visually display current machine status, including cycle and idle conditions. These indicators allow supervisors and operators to quickly assess shop activity at a glance. Built-in WiFi connectivity ensures that data is transmitted and updated in real time, supporting faster response to issues as they arise. By leveraging live data, machine shops can identify bottlenecks earlier, reduce unplanned downtime, and improve overall spindle utilization.

The EZ-SmartTower is supported by easy-to-use, free software that allows users to generate detailed reports in chart form or export data directly into Excel for deeper analysis. These reports provide insights into operational trends, machine performance, and productivity over time, helping management evaluate equipment usage and process efficiency. Importantly, all data remains internal to the machine shop and is not transferred to or stored on the cloud, addressing growing concerns around data security and intellectual property protection.

Beyond machine performance, the system also supports operator-level insights, enabling shops to track productivity in a transparent and objective manner. Real-time status updates allow operators and supervisors to make on-the-fly adjustments to workflows, while historical data can be used to establish performance benchmarks and support incentive programs tied to measurable productivity metrics.

By enabling in-depth analysis of machine and operator performance, the EZ-SmartTower supports more accurate measurement of machine throughput and capacity utilization. Its ability to clearly identify inefficiencies and constraints helps shops minimize downtime, optimize scheduling, and make better-informed decisions about equipment investment and process improvement. With the EZ-SmartTower, Lyndex-Nikken offers machine shops a practical and secure way to turn real-time data into actionable insights that drive productivity and profitability.