LK Metrology’s Focus 2025 R1 Elevates Digital Inspection with Powerful Point Cloud Capabilities!

By Ashutosh Arora

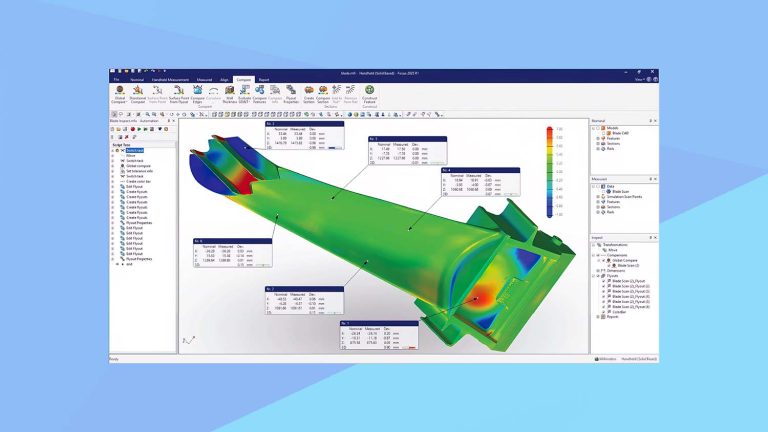

LK Metrology has introduced Focus 2025 R1, an advanced point cloud inspection software designed to significantly enhance digital measurement workflows. As part of LK Metrology’s expanding suite of inspection solutions, this intuitive 3D software integrates seamlessly with handheld scanners and measuring arms, delivering a fully guided inspection process from data capture to final reporting. The latest release incorporates the NM API 5.0 R1 laser scanner driver, ensuring optimal compatibility and performance when working with modern laser scanning hardware.

Focus 2025 R1 is engineered to provide operators with a highly intuitive environment for digital inspection. The graphical user interface offers direct access to critical tools and workflows, while a ribbon-style taskbar guides users step-by-step through the inspection process. From defining nominal CAD data, creating features and extracting GD&T information to scanning, probing, aligning and generating reports, the system ensures even complex inspection tasks can be carried out with confidence and consistency. Its seamless integration with LK’s handheld H120 laser scanner and Freedom measuring arms further strengthens its capability to handle high-precision measurement operations with ease.

A major advantage of Focus 2025 R1 is its exceptional compatibility with CAD data. The software supports a wide range of formats, from industry-standard files like STEP and IGES to native models from CATIA, NX, Creo, SolidWorks, ACIS, Parasolid and more. This extensive compatibility ensures data can flow effortlessly between design, production and quality teams, eliminating bottlenecks and simplifying cross-functional collaboration. Once imported, data acquisition, point cloud processing and report generation are tightly integrated, offering a smooth and customizable inspection experience. Deviation analyses and inspection results are displayed clearly, either graphically or in table format, making insights easy to interpret and share across departments or with external suppliers.

Focus 2025 R1 also provides advanced capabilities that position it as a powerful solution for demanding inspection environments. The software can analyze virtually unlimited point clouds, including datasets exceeding 100 million points, giving manufacturers the ability to work with highly detailed scans. The intelligent Fuse algorithm automatically creates high-quality polygon meshes by leveraging scanner metadata, while advanced feature detection tools identify everything from basic holes and slots to complex fir-tree and T-stud geometries. Support for tactile probing and a leapfrog feature makes it possible to inspect large-scale components by repositioning equipment without losing measurement continuity. Additionally, virtual assembly tools allow users to simulate assemblies using CAD or point cloud data, reducing reliance on physical fixtures and saving both time and material.

Automation is deeply embedded into Focus 2025 R1. The software enables non-stop execution of repetitive inspection tasks through macro-based action recording, eliminating the need for specialized programming knowledge. This allows teams to automate complete workflows — from CAD import through inspection to the final report — significantly improving throughput and consistency. Specialized modules such as the Airfoil Inspection package extend functionality even further, enabling precise measurement of complex aerofoil profiles and generating dedicated reports tailored to aerospace requirements.

Its broad capability makes Focus 2025 R1 suitable for a wide range of industries. In aerospace and defense, it supports critical applications including landing gear, turbine blades, structural components and MRO operations. Automotive manufacturers benefit from its accuracy in press and body, benchmarking, aerodynamics and interior fit-and-finish evaluations. The software also serves general manufacturing, heavy industries such as rail and shipbuilding, renewable energy, healthcare and consumer products — demonstrating its adaptability across diverse inspection environments.

With Focus 2025 R1, LK Metrology delivers a powerful, flexible and workflow-driven solution that enhances digital inspection accuracy, speeds up processes and strengthens quality assurance across industries.