Lantek and Zinser Partner to Optimize Bevel Cutting for Enhanced Efficiency!

By Ashutosh Arora

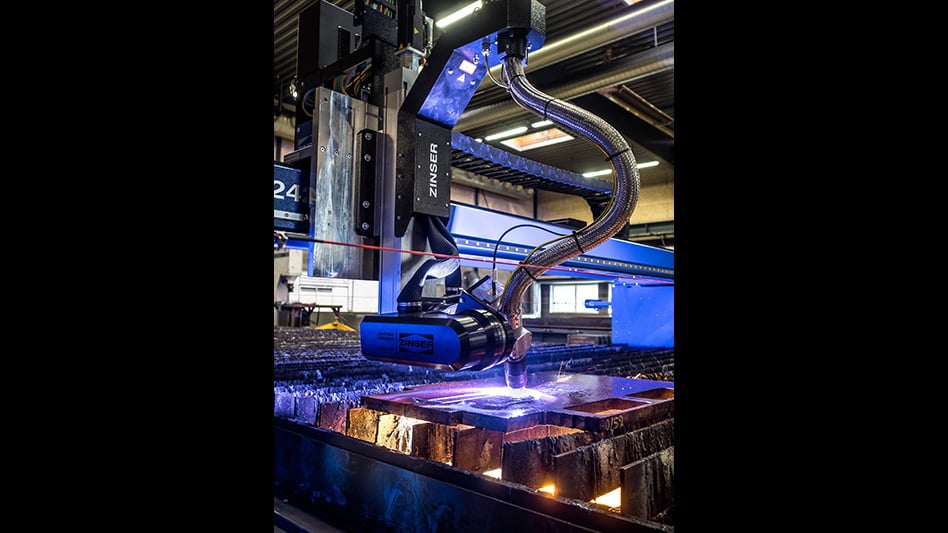

Lantek, a leading provider of sheet metal software solutions, has announced a strategic collaboration with Zinser, a manufacturer known for its advanced sheet metal and pipe cutting systems, to optimize bevel cutting processes for precut parts. This new partnership aims to streamline operations, increase precision, and reduce production downtime, particularly in high-volume and complex part production.

Zinser’s dedicated bevel cutting machines are equipped with cutting-edge technology, including optical cameras, contact sensors, and multipoint detection systems. These features allow the machines to precisely identify the geometry and orientation of parts as they are transferred from high-production cutting machines. This real-time sensory data is then processed and integrated into Lantek’s advanced software.

Lantek’s software plays a key role in the optimization of the bevel cutting process. Using a custom-developed postprocessor, Lantek’s system receives the sensory data from Zinser’s cutting machines and calculates the exact position and orientation of each part. Based on this data, the software automatically adjusts the cutting parameters, ensuring a perfect bevel cut every time. This integration of sensory data and software not only enhances the precision of the cuts but also makes the entire process more efficient.

One of the significant benefits of this collaboration is the ability to separate the bevel cutting process from the initial cutting phase. By managing bevel cutting as a distinct step, manufacturers can achieve a smoother production flow, minimizing the need for rework or adjustments in downstream processes. The automatic adjustments made by Lantek’s software help reduce downtime and improve overall throughput, making it an ideal solution for industries dealing with complex geometries and high-volume part production.

This new system is especially beneficial for parts with complex geometries where traditional bevel cutting can become cumbersome and time-consuming. By automating the process of adjusting cutting parameters and optimizing part positioning, Lantek and Zinser provide manufacturers with a tool that improves cutting efficiency, accuracy, and overall production time.

This collaboration is expected to significantly impact industries that rely on sheet metal and pipe cutting, such as aerospace, automotive, and general manufacturing. By combining Zinser’s advanced cutting technology with Lantek’s sophisticated software solutions, the partnership aims to offer a next-generation solution for managing and optimizing bevel cutting operations, providing companies with a clear competitive edge in the market.

Both Lantek and Zinser are excited about the future of their partnership and are committed to further developing and enhancing their offerings to meet the evolving needs of the manufacturing industry.