Lantek and TCI Cutting Unveil Automated Sheet Unloading System to Streamline Post-Cutting Material Handling!

By Ashutosh Arora

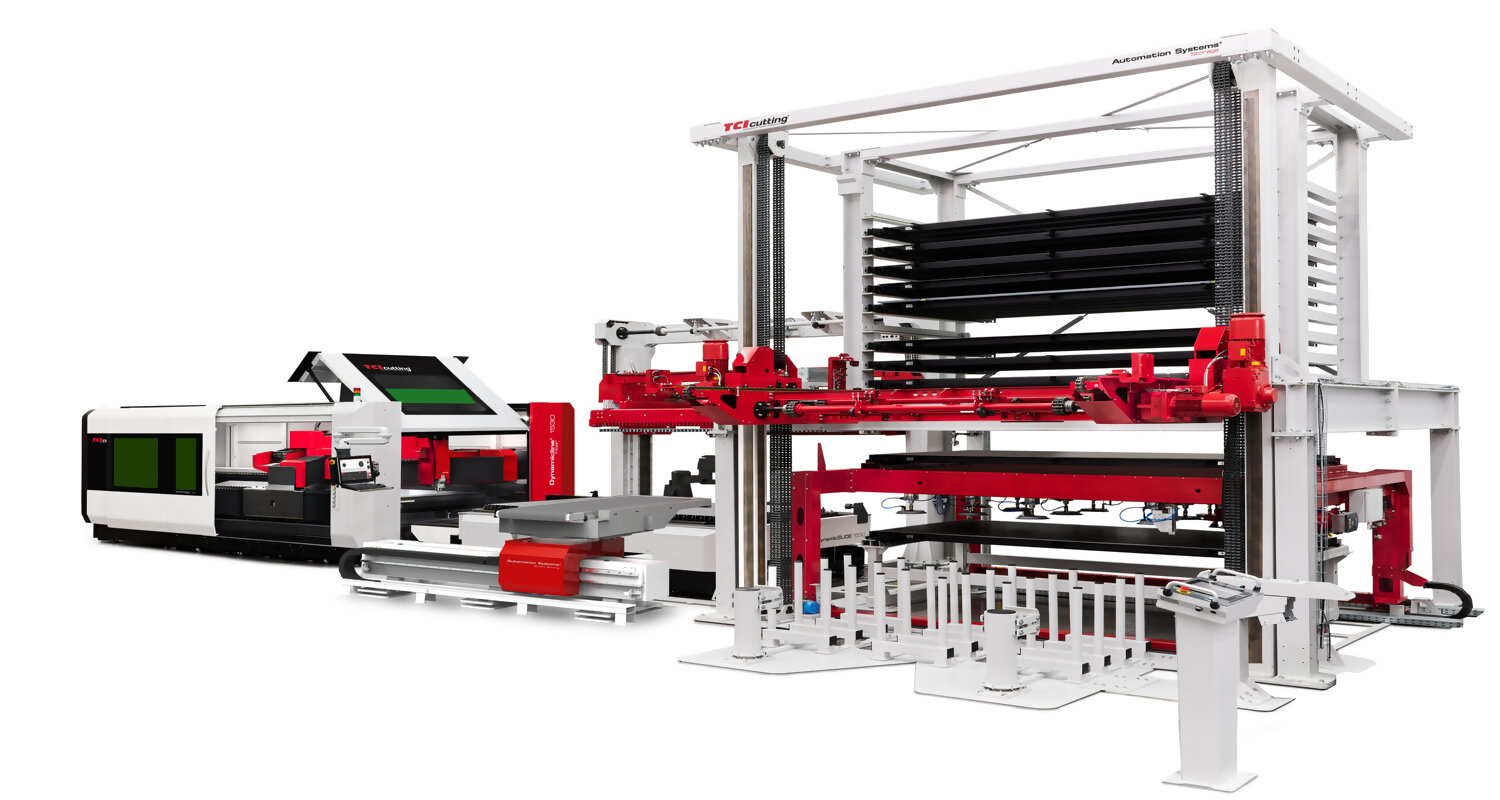

Lantek and TCI Cutting have jointly developed a cutting-edge automated sheet unloading system, designed to optimize post-cutting material handling in laser cutting operations. This innovative system eliminates the need for manual intervention, significantly reducing downtime and improving the overall production cycle efficiency.

The newly launched automated unloading system is seamlessly integrated with Lantek Expert software, providing intelligent automation capabilities for sheet metal cutting operations. Lantek Expert, a robust and industry-leading software solution for CNC laser cutting, coordinates the operation of the unloading system, enhancing precision, and enabling smoother operations by directly interfacing with the cutting process.

The system is powered by TCI Cutting’s technology, which combines an intelligent suction cup grid with the company’s Automation Systems Load & Unload platform for laser cutting machines. The suction cup grid can detect the exact position of each individual part, and it activates only the necessary suction cups, ensuring the safe and accurate handling of cut components.

One of the key advantages of this new system is its ability to eliminate the need for manual labor during the unloading process. Traditionally, the unloading of parts from laser cutting tables required operators to intervene, removing parts and sorting them for further processing. This manual intervention not only introduced the risk of human error but also slowed down the overall production cycle.

With the automated system, parts are unloaded efficiently and accurately, without the need for human involvement. The system is programmed to identify the precise location of each part, activating only the suction cups that are required to safely lift and remove the components from the cutting table. This greatly reduces manual errors and speeds up the process, ensuring that the unloading happens swiftly without affecting the quality of the cut parts.

Additionally, the system’s intelligent suction technology ensures that only the required parts are picked up, avoiding the suction of skeleton material (the remnants of the sheet after parts have been cut) or any unwanted components. This feature ensures the system operates without disturbing leftover scrap material, contributing to a cleaner workspace and reducing the need for post-cutting cleanup.

The collaboration between Lantek and TCI Cutting also ensures the system is specifically designed to enhance laser cutting operations. By reducing the reliance on manual labor, the system contributes to faster cycle times and enables lights-out operations, where the machine can continue to run even when operators are not present. This automation not only leads to increased production capacity but also improves workplace safety by removing operators from potential risks associated with manual unloading.

Furthermore, this system is a crucial step in driving Industry 4.0 automation in manufacturing. The integration of advanced sensors, real-time data collection, and seamless software control reflects the increasing trend toward smart factories and digitally connected operations, where every aspect of production is optimized for efficiency and precision.

Key Benefits for Manufacturers:

- Enhanced Efficiency: The automated unloading system speeds up the post-cutting process, significantly reducing cycle times and ensuring faster throughput.

- Reduction in Labor Costs: By eliminating manual unloading, manufacturers can reduce their labor costs and increase worker safety by removing the need for human intervention during critical post-cutting processes.

- Improved Quality Control: The system’s precise and automated handling capabilities reduce the risk of human error and ensure that each part is safely and accurately removed, enhancing the overall quality of the process.

- Integration with Existing Systems: The system integrates seamlessly with the Lantek Expert software, making it compatible with a wide range of laser cutting machines and offering flexibility to manufacturers.

- Increased Production Flexibility: With the ability to handle varying sizes and types of parts automatically, the system provides manufacturers with greater flexibility in their production processes, accommodating both small and large batch runs.

The Lantek-TCI Cutting automated sheet unloading system marks a significant advancement in laser cutting automation, providing manufacturers with a reliable solution to streamline post-cutting material handling. By removing manual intervention and optimizing part handling, manufacturers can achieve faster production times, improve safety, and reduce operational costs, ultimately leading to more efficient and profitable manufacturing operations. As automation continues to shape the future of manufacturing, systems like these offer a glimpse of the advanced, smart factories of tomorrow.