Kaiser Threading Inserts Enhance Versatility in Acme Threading Applications!

By Ashutosh Arora

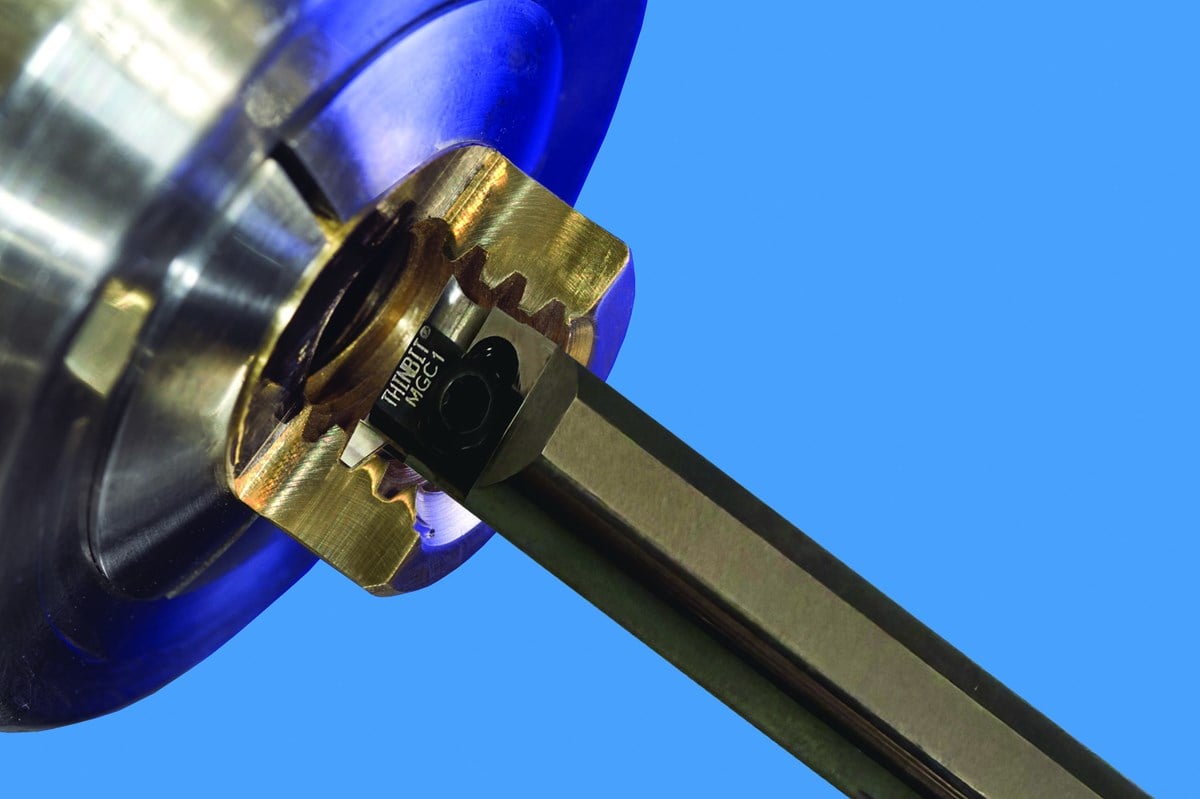

Kaiser Tool Co. has expanded its popular Thinbit Mini Groove ‘N Turn line by introducing Acme threading inserts, designed for a wide range of threading applications. These inserts, perfect for cutting thread sizes of six threads per inch and greater, are engineered to tackle standard 29-degree Acme thread profiles, offering versatility and precision in various industries.

The new inserts are capable of cutting both centralizing and stub profiles by overcutting. They can also be used for internal Acme threads on parts with bore diameters of 0.325″ and larger, making them suitable for a variety of applications. These tools provide superior geometry for efficient cutting, ensuring high-quality results in demanding environments.

Available in submicron-grain carbide grades, the Mini Groove ‘N Turn Acme threading inserts can be selected either uncoated or with a variety of coatings, including TiN, TiCN, TiAIN, and diamond film. This flexibility in coatings enhances tool life and performance across both ferrous and nonferrous materials.

These inserts can be utilized on conventional machines, Swiss-style machines, and CNC equipment, expanding their usability across different manufacturing setups. Toolholders for the inserts come in round shank sizes of 1/4″, 3/8″, 1/2″, and 5/8″, made from steel, heavy metal, and carbide to ensure the perfect fit for each machine.

The Mini Groove ‘N Turn Acme threading inserts are designed to fit existing MGT series Thinbit toolholders, providing ease of integration into a wide array of threading operations. Thinbit’s expansive selection of 60-degree and Acme thread forms for internal and external threading further cements its reputation as a leader in precision tooling solutions.