Japan Installs Its Largest-Class Metal PBF Industrial 3D Printer to Scale Advanced Manufacturing!

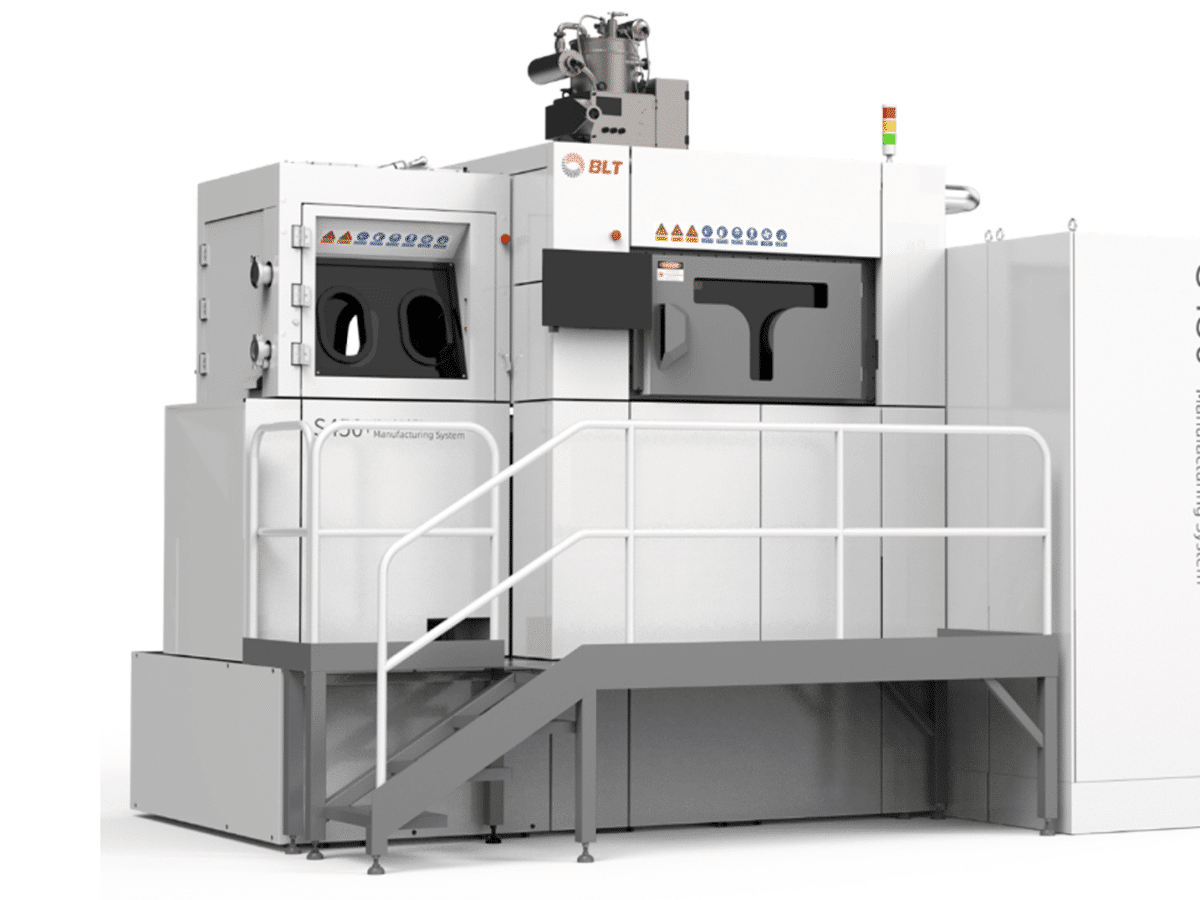

Japan is set to take a major leap in industrial additive manufacturing with the installation of its largest-class metal powder bed fusion (PBF) 3D printer, supplied by Bright Laser Technologies (BLT) through Orix Rentec Corporation. Scheduled for deployment in April 2026 at Nihon Chuzo Co, Ltd, the system represents a national milestone in metal 3D printing capacity and marks a decisive step toward large-format, high-speed industrial production.

According to reports from leading Japanese publications including Nikkei, Sangyo Shimbun and Tekko Shimbun, the new BLT system will dramatically expand Nihon Chuzo’s manufacturing capabilities. The build volume will increase from the company’s current 260 × 260 × 290 mm to an expansive 450 × 450 × 500 mm—more than five times larger in usable build space. This significant scale-up enables the production of large and complex components that were previously beyond reach.

A key upgrade lies in the printer’s laser architecture. Nihon Chuzo will move from a single-laser configuration to BLT’s advanced eight-laser system, allowing high-speed, parallel processing across the large build area. This enhancement is expected to substantially improve productivity, reduce per-part manufacturing costs and shorten delivery timelines, making additive manufacturing viable for higher-volume industrial applications.

One of the most important outcomes of this installation is the ability to manufacture 12-inch (φ304.8 mm) semiconductor wafers—components that existing metal 3D printers at the company cannot support due to size constraints. The expanded capacity positions Nihon Chuzo to serve advanced semiconductor equipment and other high-value industrial sectors that demand precision, scale and reliability.

Beyond capacity expansion, Japanese media highlight that the project supports Nihon Chuzo’s broader digital transformation strategy. The company plans to shift selected cast components to metal 3D printing, improving production efficiency while addressing labour shortages caused by Japan’s ageing workforce. By reducing dependence on traditional casting workflows for suitable parts, the company aims to lower costs and increase manufacturing flexibility.

BLT was selected for this landmark installation due to its proven large-format PBF technology, stable long-duration multi-laser printing performance and complete end-to-end ecosystem. The platform integrates hardware, materials, software and application support, offering a mature and industrially validated solution. For Nihon Chuzo—a century-old foundry within the JFE Group ecosystem known for heavy industrial and advanced casting expertise—the system aligns with its long-term vision of innovation and competitiveness.

The installation of Japan’s largest-class metal PBF 3D printer is widely seen as a strategic milestone for the country’s manufacturing sector. By enabling large-scale additive manufacturing for semiconductors, heavy machinery and high-value industrial components, the project strengthens Japan’s position in next-generation production technologies and underscores the growing role of metal 3D printing in industrial digitalisation.