Iscar’s NeoSwiss Quick-Change System Enhances Machining Stability and Productivity!

By Ashutosh Arora

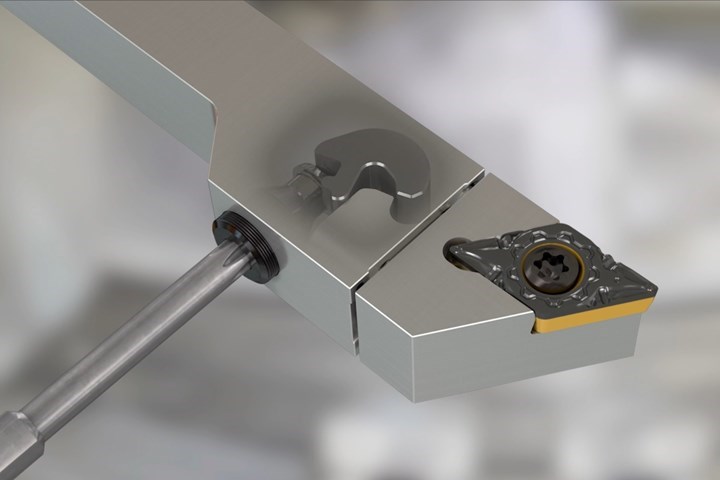

At PMTS 2025, Iscar is showcasing its innovative NeoSwiss modular quick-change head system, designed specifically for Swiss-type machines. This system offers versatility for various applications such as turning, grooving, parting, and threading. One of its standout features is the clamping mechanism, which ensures high repeatability, maintaining an impressive position accuracy of ±0.0008″ during head replacements.

The system utilizes a rotary wedge mechanism that enhances clamping force between the head and the shank, significantly boosting machining stability. This increased stability minimizes harmonics, allowing operators to work at higher parameters while extending tool life and improving overall productivity.

The NeoSwiss system is also designed for flexibility, as it accommodates both X- and Y-axis heads on the same shank. This feature helps to reduce tool bending and vibration under high machining conditions, resulting in better surface quality and improved chip control.

Additionally, Iscar’s tools come equipped with coolant ports capable of handling 2,000-psi pressure, which improves chip control and extends tool life. By leveraging Computational Fluid Dynamics (CFD) technology, Iscar has optimized coolant flow, ensuring consistent performance while minimizing pressure drops for enhanced tool efficiency and longevity.