ISCAR Boosts Titanium Machining Capabilities with Expanded ECKI-H4R-CF Endmill Line!

By Ashutosh Arora

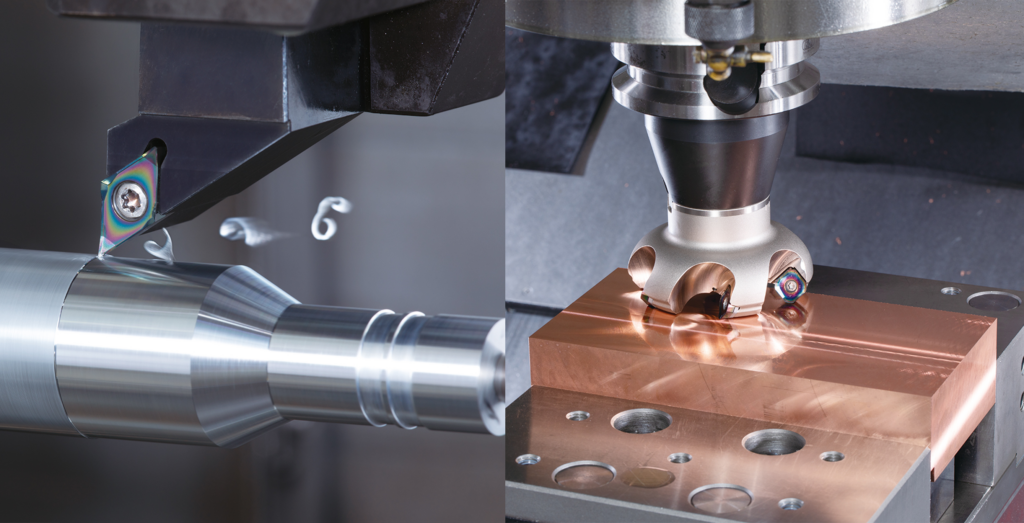

ISCAR, a renowned name in cutting tool innovation, has announced the expansion of its ECKI-H4R-CF solid carbide endmill line, designed to raise the bar in titanium machining performance. The updated line now includes a 1-inch diameter variant and a broader selection of corner radii options—advancing ISCAR’s mission to deliver optimized solutions for demanding sectors such as aerospace, medical, and general engineering.

Engineered for high-efficiency machining, the ECKI-H4R-CF series excels in full slotting operations up to 2xD. Its 4-flute configuration, combined with variable pitch and multiple helix angles, helps significantly reduce vibration and chatter, allowing for smoother cuts and extended tool life, even under high-load conditions.

What sets these endmills apart is ISCAR’s proprietary IC900 carbide grade—recognized for its exceptional performance in hard-to-machine materials like titanium. The tools are also treated with a PVD (Physical Vapor Deposition) coating, enhancing wear resistance and ensuring longevity during intensive and extended use.

To meet the needs of a diverse customer base, the ECKI-H4R-CF endmills are available with cylindrical, Weldon, and Safe-Lock® shank options. This versatility ensures that the tools can be seamlessly integrated into a wide range of machining environments and setups, enhancing both compatibility and operational efficiency.

These innovations are especially critical in the aerospace sector, where titanium’s strength-to-weight ratio makes it a material of choice—but also one that poses machining challenges. With ISCAR’s new endmills, manufacturers can achieve higher precision and superior surface finishes while maintaining the robust performance required in such applications. Likewise, in the medical device industry, where consistent dimensional accuracy and surface quality are essential, the updated tools offer confidence and capability.

By expanding the ECKI-H4R-CF line, ISCAR reinforces its commitment to providing advanced tooling solutions that not only meet current industry needs but also anticipate future demands. The inclusion of additional sizes and radii highlights the company’s responsiveness to market feedback and its focus on continuous improvement.

With productivity, precision, and adaptability as core priorities, ISCAR’s ECKI-H4R-CF line gives manufacturers the tools needed to reduce costs per part while maintaining top-tier quality. Whether applied in aggressive roughing or detailed finishing tasks, these endmills deliver the durability and performance that today’s complex materials and geometries require.

For detailed specifications, corner radius options, and ordering information, customers can explore ISCAR’s official product page and consult with technical representatives to find the ideal configuration for their application.