Hexagon’s ESPRIT Edge Empowers Swiss-Type Machining with AI-Driven Precision and Productivity Boost!

By Ashutosh Arora

Hexagon Manufacturing Intelligence has unveiled a game-changing update to its ESPRIT Edge CAM software, bringing advanced Swiss-type machining capabilities and AI-powered tools to the forefront of modern manufacturing. Designed to tackle the increasing complexity of multi-axis machine programming and the widening skills gap in precision machining, the latest release—ESPRIT Edge 2025.2—marks a pivotal step in making high-performance Swiss machining more accessible, efficient, and scalable.

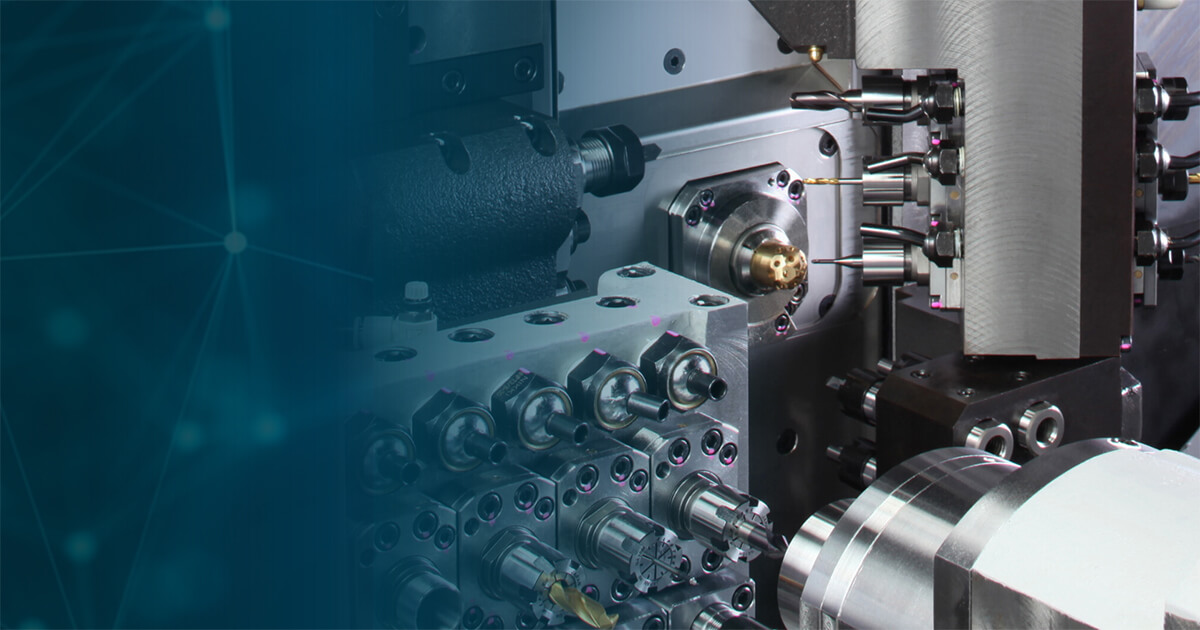

For the first time, ESPRIT Edge introduces robust support for Swiss-type lathes, including complex platforms like the Citizen L-series and Star SR-series. At its core is a high-fidelity digital twin, offering real-time, collision-free simulation and intelligent control over key machine functions such as superimposition, composite axis synchronization, and automatic prepositioning. These enhancements allow manufacturers to streamline setup, eliminate trial-and-error, and optimize throughput while maintaining precision and safety.

Complementing its machine control capabilities, ESPRIT Edge simplifies hardware configuration with intuitive tools for collet, guide bushing, and tool mounting block setup. Features like automatic synchronization, adaptive machining cycles, and tilted plane rotation further reduce manual programming and help shops efficiently manage multichannel operations, cutting down cycle times and minimizing errors.

What truly sets ESPRIT Edge 2025.2 apart is its seamless integration with Hexagon’s cloud-based Nexus platform, which delivers AI-powered services to automate tasks and guide programmers:

- Hexagon Copilot: A smart, 24/7 virtual assistant that leverages natural language processing to offer expert advice, programming support, and contextual insights within the ESPRIT Edge interface—ideal for both seasoned and novice users.

- ProPlanAI: A self-learning process planning tool that uses historical machining data to optimize programs for new parts, reducing manual input and accelerating time-to-production.

Together, these AI tools democratize advanced machining by shortening training times, enhancing programming consistency, and enabling new users to achieve expert-level productivity with minimal ramp-up.

Tailored G-code output eliminates the need for postprocessor customization, ensuring seamless execution on OEM-specific machines. With a focus on standardization, simulation accuracy, and workflow reliability, ESPRIT Edge enables manufacturers to embrace complex Swiss machining without being hindered by technical limitations or resource constraints.

With the launch of ESPRIT Edge 2025.2, Hexagon not only addresses the legacy challenges of Swiss-type programming but also lays the groundwork for a smarter, more agile future in CAM—where innovation, precision, and productivity work hand-in-hand to drive manufacturing success.