Hexagon Integrates WORKNC CAM with Cloud Tool Library to Accelerate Programming of Complex Parts!

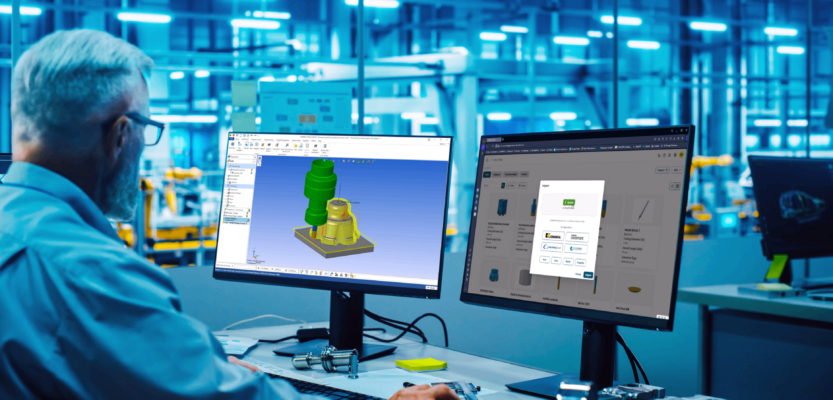

**Hexagon, through its Manufacturing Intelligence Division, has introduced a production-ready integration between its *WORKNC* CAM software and a cloud-based tool library, aimed at significantly improving programming speed, consistency, and predictability for complex machining applications.** The integration strengthens how CAM programmers access and apply validated tooling data and proven machining methods, addressing some of the most persistent challenges faced by modern machine shops.

As part geometries become more complex and tolerances tighter, manufacturers are under increasing pressure to deliver high-quality components faster, often with fewer experienced programmers available on the shop floor. In many cases, valuable time is lost recreating tooling assemblies, managing fragmented tool data across systems, or relying on undocumented knowledge passed informally between shifts. Hexagon’s latest WORKNC release is designed to eliminate these inefficiencies by combining enhanced workflow automation with centralized, OEM-validated cutting-tool data.

The integrated tool library provides WORKNC users with direct access to verified cutting-tool information from a growing ecosystem of leading tooling partners. Instead of manually re-entering tool data or rebuilding tool models, programmers can now pull complete tooling assemblies directly into the CAM environment. This ensures that digital tool definitions accurately reflect real-world cutting performance, reducing setup time and minimizing discrepancies between programmed and actual machining conditions.

The expanding partner ecosystem supporting the tool library includes platforms such as MachiningCloud and ToolsUnited, with additional tooling partners being onboarded as the system grows. This broader access to standardized and validated tooling data gives machine shops greater flexibility while maintaining consistency across jobs, machines, and teams.

A key benefit of the integration is the ability to create accurate digital twins of cutting tools and assemblies. These digital representations allow WORKNC to automatically apply material-specific cutting data and standardized tooling definitions throughout the programming process. Because the tool library is cloud-based, it supports scalability across thousands of tool items while maintaining consistency across multiple users, departments, or facilities. Searchable OEM catalogs can be accessed directly within the CAM workflow, without the need for additional applications or consuming extra CAM licenses.

According to Steffen Dilger, reliable tooling information is one of the most powerful drivers for reducing programming time and eliminating variability in machining. As manufacturers increasingly adopt automation and AI-assisted programming, centralized and high-quality tool data becomes critical for stable and repeatable outcomes. Hexagon’s approach focuses on removing workflow bottlenecks and creating a connected manufacturing environment that spans tool selection, simulation, and NC code verification.

Alongside the tool library integration, Hexagon has also introduced automation and finishing enhancements within WORKNC to further simplify complex programming tasks. A new parallel finishing algorithm improves surface quality by delivering cleaner transitions at edges and enhancing geometric accuracy. When combined with toolpath extension in tangency, it reduces the need for extensive CAD preparation. Additional programming enhancements improve the detection of remaining material and provide finer control over tool entry and exit positions, enabling collision-safe toolpaths with less manual intervention.

Together, these developments position the integrated WorkNC and cloud tool library solution as a practical response to growing complexity, skills shortages, and productivity demands in modern machining environments, helping shops program faster, reduce variability, and achieve more consistent machining results.