Hexagon Elevates Quality Control with AI-Enhanced VGStudio Max 2025.3

By Ashutosh Arora

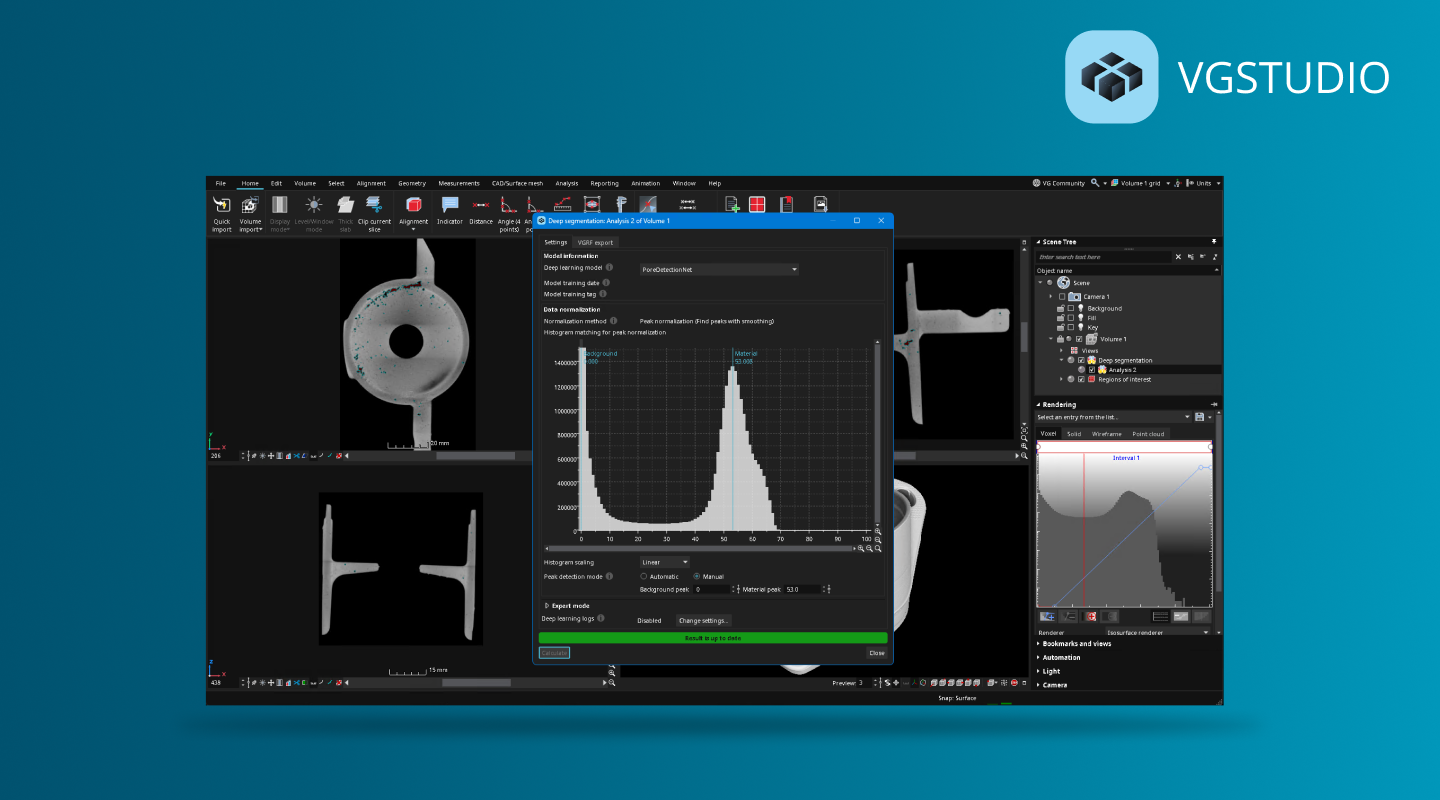

Hexagon Manufacturing Intelligence has introduced the 2025.3 release of its VGStudio Max software, setting a new standard in inspection and measurement for industries where precision and reliability are paramount. This latest version comes with a redesigned and AI-powered porosity and inclusion analysis (PIA) tool, streamlining quality control processes for manufacturers in automotive, aerospace, and other sectors that rely on CT-scan data to verify part integrity.

The enhanced PIA tool leverages artificial intelligence to accelerate the detection and classification of pores and inclusions that may be hidden deep within metal, plastic, or composite parts. By quickly identifying discrepancies from the earliest stages of product development through final production, the software helps manufacturers address potential defects before they become costly issues. This not only improves the quality of finished components but also strengthens overall manufacturing efficiency and customer confidence.

Beyond the AI upgrade, Hexagon has added powerful capabilities to make the software more intuitive and versatile. The new multipart coordinate measurement functionality, for instance, simplifies complex projects by allowing users to view, analyze, and edit measurement plans for multiple parts in one centralized environment. Essential statistics for individual features are now integrated directly into the feature list, while interactive plotting tools allow users to compare values across different parts. Users can even edit, remove, or transfer features and geometry elements between parts seamlessly, creating a more efficient workflow.

Another advancement in this release is the ability to create and adjust dimensions directly within the 3D view. By simply dragging and dropping measurement lines, users can intuitively place and modify dimensioning features in the correct orientation with optimal visibility. Holding the “Alt” key enables the creation of projected dimensions on a preview plane, ensuring that all lines remain visible and adjustable, even when located within the material. This functionality enhances user control and reduces time spent on repetitive tasks, particularly for complex geometries.

Hexagon has also addressed challenges associated with optical scanning, especially in scenarios where scans may be incomplete due to equipment limitations or restricted access to certain surfaces. The improved deformation field capabilities allow the software to handle morphing and matching of incomplete scans with greater accuracy, even in one-sided scanning conditions. This ensures that optical scans can be used more reliably for precise analysis, reducing the risk of errors in quality assurance workflows.

Additionally, the 2025.3 version broadens interoperability by enhancing mesh import and export functions. With support for GLB/GLTF, AMF, and 3MF file formats, users can now exchange 3D surface data more freely with other applications. For example, additive manufacturing professionals can import mesh data stored in AMF or 3MF formats directly as nominal reference data, without time-consuming conversions. Similarly, colored meshes generated from analysis results can be exported in GLB format for use in external applications, including presentation tools like PowerPoint, making results more accessible and visually clear.

With these advancements, Hexagon’s VGStudio Max 2025.3 provides manufacturers with a powerful, AI-driven inspection platform that improves accuracy, speeds up workflows, and integrates seamlessly with other digital tools. By combining artificial intelligence with user-friendly design and extended interoperability, Hexagon is enabling smarter, faster, and more reliable quality control across a wide range of industries.