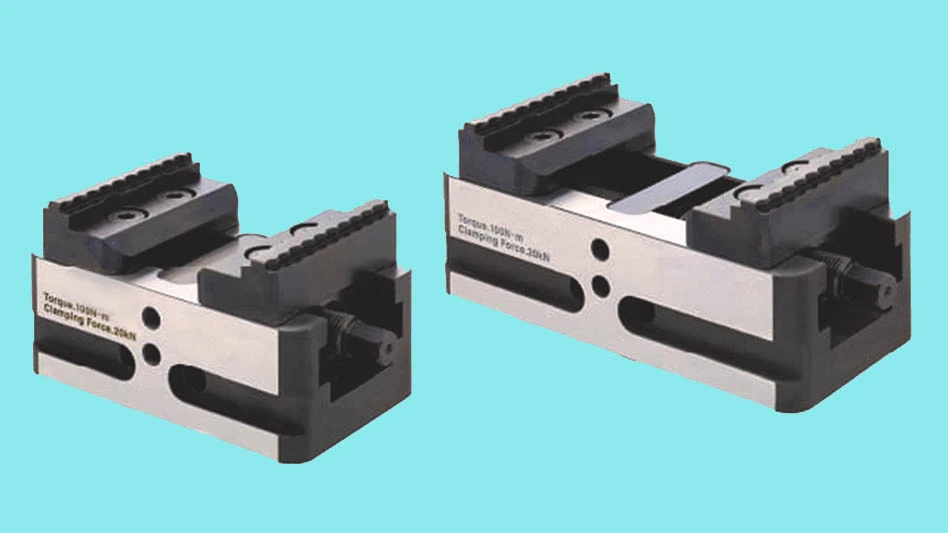

Fixtureworks Introduces CP170-N Centring Vises for Precision and High Clamping Force Applications!

By Ashutosh Arora

Fixtureworks has expanded its lineup of advanced workholding solutions with the introduction of the CP170-N centring vises. Designed as part of a comprehensive clamping system that includes centring clamps, jaws, flex zero bases, and clamping pins, these vises deliver superior stability, precision, and high clamping performance for demanding machining environments.

The CP170-N vises feature self-centring, centre-moving jaws that provide balanced and stable clamping. Available in two body lengths—130 mm and 170 mm—and widths of 80 mm or 120 mm, these vises are engineered to withstand heavy-duty operations, offering a powerful clamping force of up to 4,500 lb. The vise bodies are constructed from high-strength 4140 steel, which is induction hardened, precision ground, and finished with a durable black oxide coating for enhanced corrosion resistance. To simplify installation, each vise is supplied with four locating screws for secure and accurate mounting.

Users can choose between two jaw configurations—dovetail and serrated—both designed to provide reliable workpiece centring with minimal surface contact. The dovetail jaws hold the workpiece firmly on two surfaces, ensuring positive and repeatable clamping ideal for precision machining and repeat setups. The serrated jaws, on the other hand, are intended for more aggressive cutting conditions, penetrating the workpiece surface to maintain a firm grip during high-force operations. Both jaw types are made from quenched and tempered 4140 steel, black oxide coated to withstand wear and extend service life.

The CP170-N vises integrate seamlessly with Fixtureworks’ flex zero base system, which is optimized for five-axis machining. These bases eliminate tool interference and allow full access to the workpiece, improving machining efficiency. Available in 240 mm and 150 mm square configurations, the bases feature a four-point clamping mechanism that enables quick, secure setup in a single operation. They also offer exceptional locating repeatability, with a tolerance of just 0.005 mm, ensuring precise positioning every time.

When paired with CP185 clamping pins—available separately—the flex zero bases can be fully clamped or released with approximately three rotations of a clamping key, streamlining the workflow and reducing setup time. The system also includes four mounting pins and protective covers for unused grid holes, providing a complete, ready-to-use setup for flexible and efficient machining operations.

With the CP170-N centring vises and compatible components, Fixtureworks delivers a versatile clamping solution that meets the precision, durability, and productivity demands of modern metalworking. The combination of strong clamping force, hardened construction, and high repeatability makes this system ideal for manufacturers seeking to optimize their five-axis machining operations while maintaining accuracy and efficiency across production runs.