Dürr and GROB Unveil Next-Generation Concept Factory for Battery Cell Production!

By Ashutosh Arora

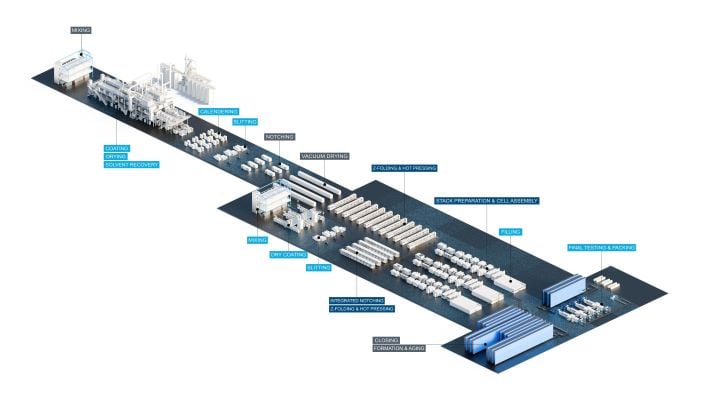

Engineering leaders Dürr and GROB have joined forces to introduce a pioneering concept factory for lithium-ion battery cell production — a breakthrough designed to set new industry standards in energy efficiency, space optimization, and product quality. Unveiled at The Battery Show India 2025 in Greater Noida, the concept represents a major leap forward in sustainable and intelligent manufacturing for the global battery industry.

At the core of this next-generation factory is a combination of dry electrode coating and GROB’s advanced Z-folder assembly technology with integrated notching. This synergy delivers a production system that requires 50% less floor space and consumes up to 70% less energy compared to traditional setups — all while ensuring superior cell uniformity and performance. The integration of these innovations not only reduces operational costs but also supports cleaner, more efficient battery manufacturing aligned with global sustainability goals.

Since initiating their partnership in 2022, Dürr and GROB have been working together to create end-to-end lithium-ion battery manufacturing solutions for clients across Europe, North America, and India. Their joint objective is to become comprehensive system suppliers offering high-performance, localized production solutions. This collaboration aligns closely with India’s Atmanirbhar Bharat vision, promoting domestic manufacturing capabilities in clean energy and mobility technologies.

“We are driving India’s clean mobility transition through advanced lithium-ion battery manufacturing systems that merge global engineering expertise with localized production and service,” said Aji Philip, Head of LiB at Dürr India. GROB Group CEO German Wankmiller added, “Our joint portfolio now spans nearly the entire battery cell production value chain, offering comprehensive, high-performance technologies for the global market.”

Central to the concept is Dürr’s X.Cellify DC system, which leverages the Activated Dry Electrode® process developed with LiCAP Technologies. Unlike traditional slurry-based coating methods, this dry electrode process uses a solvent-free approach — forming a calendered free-standing film that is laminated directly onto the collector foil. The result is a manufacturing method that completely eliminates drying, solvent recovery, and waste treatment steps, reducing both costs and environmental impact. Excess film material can also be recycled back into production, enhancing sustainability and resource efficiency.

Following successful proof-of-concept trials, Dürr has demonstrated that its dry coating technology consistently delivers high-quality output. The company is now engaging with pilot partners to scale industrial deployment. Meanwhile, GROB’s innovative Z-folder system integrates electrode notching directly into the folding sequence, allowing faster throughput, smaller production footprints, and exceptional system stability. Its advanced web-tension control and electrode-handling systems ensure precision, achieving up to 95% system availability.

Further advancing battery cell production, Dürr has also developed a high-pressure electrolyte filling process capable of operating at up to 30 bar — two to three times higher than conventional systems. This enables more accurate dosing, quicker filling times, and deeper electrolyte penetration, enhancing both efficiency and cell performance.

The concept factory embodies full digital integration from design to production. A digital twin enables complete simulation of the facility during the planning stage, reducing commissioning time and accelerating production ramp-up. Real-time data from every process stage is managed through iTAC’s MES/MOM software (a Dürr subsidiary), ensuring full traceability, analytics, and quality assurance across the production line.

By merging advanced engineering with digital intelligence, Dürr and GROB’s concept factory signals the future of scalable, sustainable, and high-precision battery manufacturing — paving the way for cleaner energy systems and a smarter industrial ecosystem.