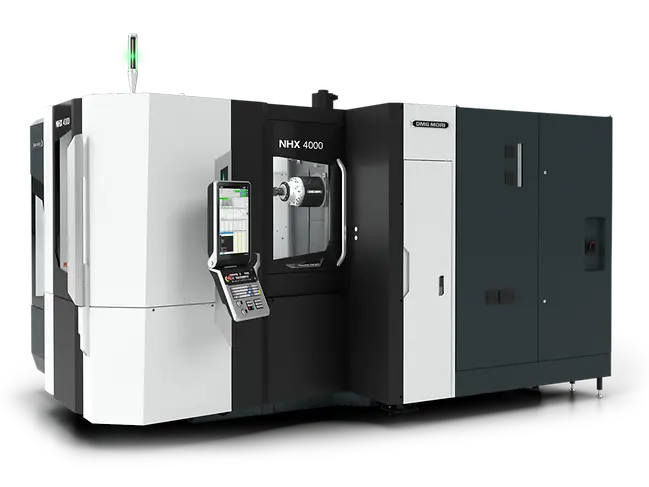

DMG MORI Unveils 4th Generation NHX Horizontal Machining Centers Focused on Energy Efficiency and Smart Production!

By Ashutosh Arora

DMG MORI Co. Ltd. has introduced the latest additions to its horizontal machining center lineup — the NHX 4000 and NHX 5000 4th Generation models — engineered to deliver high-speed, high-precision, and energy-efficient performance for next-generation manufacturing. Designed with sustainability and productivity in mind, these machines combine faster cycle times, reduced energy consumption, and simplified maintenance, making them ideal for industries such as aerospace, electric vehicles (EV), semiconductors, construction machinery, and mold manufacturing.

At the core of the new NHX 4th Generation series lies a design philosophy centered on efficiency. Through advanced inverter and coolant control, the machines minimize power usage without compromising machining performance. Their innovative chip management systems enhance operational stability, enabling fast, consistent, and cost-effective production in demanding industrial environments.

A major highlight is the Speedmaster spindle, which operates at 400 V and delivers up to 50% more output compared to earlier generations. With rapid traverse speeds reaching 70 m/min, operators can expect significantly reduced cycle times and enhanced throughput. DMG MORI has also addressed one of the biggest challenges in modern manufacturing—maintenance—by integrating intelligent systems for chip, coolant, and mist management. The Zero-Sludge Coolant Pro system features a large vertical coolant tank that supports extended, unmanned operations, drastically cutting maintenance requirements while ensuring continuous precision machining.

In keeping with DMG MORI’s commitment to automation and digitalization, the new NHX machines are equipped with the advanced Ergoline X control panel. This control interface combines a widescreen touch display with physical buttons, offering an intuitive and user-friendly experience. Supporting this hardware is the Celos X software platform, which enables smart connectivity, data-driven process optimization, and seamless integration with modern digital manufacturing ecosystems.

The NHX 4th Generation line embodies DMG MORI’s vision of sustainable production. Energy consumption of peripheral equipment is further optimized through innovations like integrated coolant pumps, inverter-based energy control, and intelligent valve management — all contributing to a smaller environmental footprint and lower total cost of ownership.

The company also revealed that additional models — including the NHX 5500, 6300, and 8000 4th Generation — are currently under development, promising even greater versatility and performance across different workpiece sizes and applications.

DMG MORI Manufacturing USA Inc. will produce these 4th Generation NHX machines at its state-of-the-art facility in Davis, California. Production is scheduled to begin in February 2026, with the first batch of machines expected to roll out by the end of Q1 2026.

By combining speed, sustainability, and smart digital integration, DMG MORI’s NHX 4th Generation HMCs mark a significant advancement in horizontal machining technology — empowering manufacturers to achieve higher productivity while advancing toward greener, smarter, and more efficient production systems.