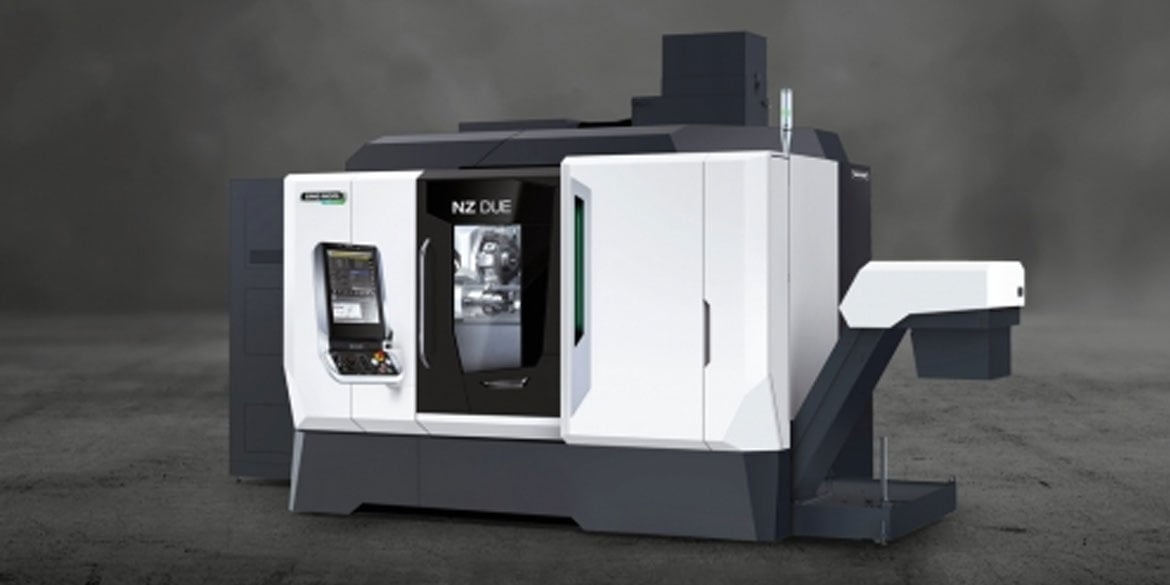

DMG MORI has integrated its decades of experience in production turning and customized customer solutions into the development of the new NZ series. The result is a highly modular platform, available in two versions of the machine base, which offers customers maximum flexibility and productivity: the modular system includes bar and back machining, the possibility of installing two, three or four machining units. with B axis and an additional spindle in the Z axis. And that’s not all: DMG MORI’s offer also includes various automation solutions for the NZ platform.

Available in two machine bed versions, the new NZ platform allows the machining of a wide range of components. The short version is designed for workpieces up to 740mm in length, while the long version has enough space to accommodate workpieces up to 1290mm. Both solutions allow reworking up to a diameter of ø 120 mm, while for the machining of the bar the passage of the bar is ø 65 mm. Even taking into account the 3.30 m long bar feeder, the NZ occupies only 17.8 m² of floor space. Stability and precision in machining are guaranteed by its symmetrical structure with high thermal stability and uniform chip fall in all positions. As far as CNC control is concerned, the NZ platform is equipped with a 19 “DMG MORI SLIMline Touch Panel and FANUC 30iB.

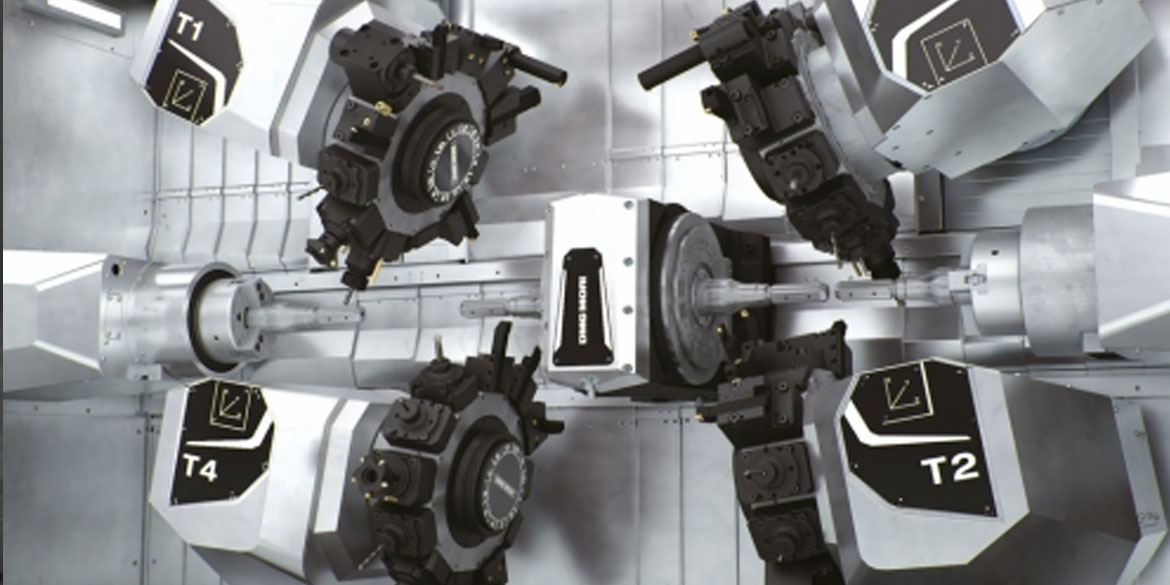

Maximum modularity up to four milling units

Highlights of the NZ platform are its customized configuration options, so much so that each user can install a bespoke production solution designed to meet their needs. Thanks to the modular machine concept, the NZ platform offers the customer the NZ DUE, NZ TRE and NZ QUATTRO models, depending on whether two, three or four milling units are installed in the work area. Each of these units can be positioned freely and is equipped with a Y axis with a stroke of 80 mm and a B axis with a swiveling range from -10 ° to + 100 °. There is also the option of a TWIN Spindle in the Z axis with a diameter of ø 65 mm. This spindle acts as a hydraulic tailstock and offers the Swisstype function with rotation speeds of up to 5,000 rpm in the guide bushing. In the end,

Even greater productivity with automation solutions

DMG MORI offers a wide range of automation solutions to ensure customers long-term competitiveness with the NZ platform. The integrated workpiece unloading system, the bar loader, as well as the autonomous production with one or two gantry loaders or with a robot in the work area stand out in the offer portfolio. And not only that: the NZ platform is also available with Robo2Go or MATRIS.