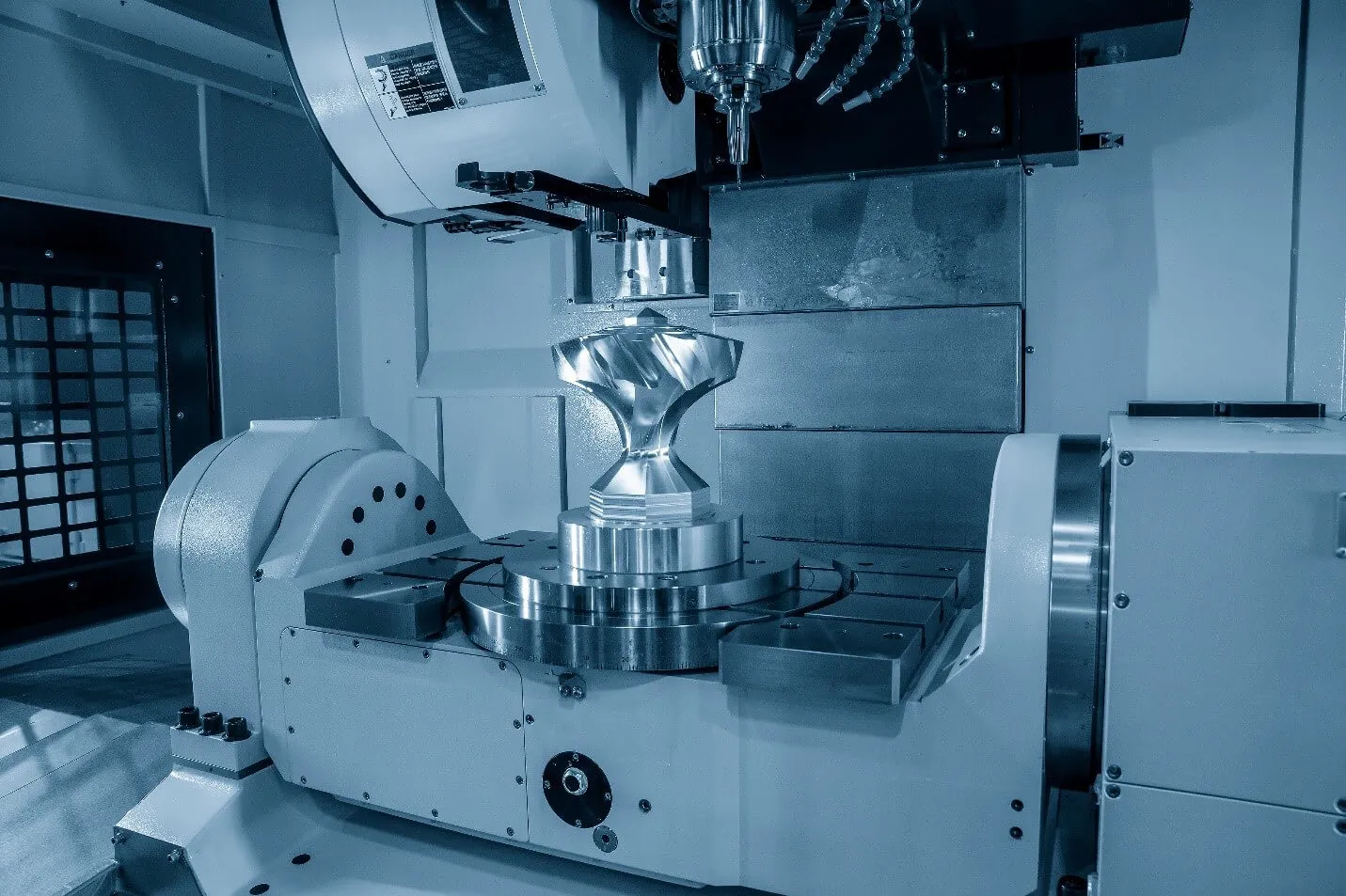

DMG MORI CTX 450 4A Enables Flexible Six-Sided Complete Machining

DMG MORI has expanded its latest generation of universal turning centres with the introduction of the CTX 450 4A, engineered to deliver flexible six-sided complete machining within a compact footprint. The new model combines dual spindles, multiple tool carriers and a rigid mechanical structure to support precise and productive turning operations, particularly for small and medium-sized manufacturers handling complex components.

The CTX 450 4A offers up to 36 tool positions distributed across two tool carriers that can operate independently or simultaneously. This configuration enables high flexibility for machining on both spindles, reducing cycle times and allowing complete part processing in a single setup. The machine’s rigid construction, integrated cooling system and Magnescale position measuring systems on the X- and Y-axes — with optional coverage on the Z-axis — support positioning accuracy of up to 6 microns, ensuring consistent machining quality.

Occupying a footprint of 10.8 square metres, the turning centre accommodates workpieces up to 430 mm in diameter and 700 mm in length. The Y-axis travel of plus or minus 65 mm expands machining capability for off-centre operations and complex geometries. Standard spindle configurations deliver strong turning performance, while optional spindle variants provide torque up to 620 Nm for heavy-duty applications. A bar capacity of up to 102 mm supports diverse production scenarios, from batch production to high-mix manufacturing.

Turret options include multiple VDI configurations, with milling and drilling speeds reaching up to 12,000 rpm. This flexibility allows the CTX 450 4A to adapt to varying part requirements, supporting turning, milling and drilling operations within a single machine platform.

Automation options enhance productivity further. An integrated unloading device is available for components up to 100 mm by 350 mm and 4 kg, while robotic handling systems can be added for higher levels of automation. Digital integration is provided through the CELOS X control platform, compatible with Siemens SINUMERIK ONE or MAPPS controls. The system supports app-based operation and streamlined integration into connected manufacturing environments. Built-in technology cycles simplify programming and contribute to more efficient machining workflows.

Energy efficiency is addressed through DMG MORI’s GREENMODE measures, which can reduce energy consumption by more than 30 percent depending on configuration. Features include low-friction linear guides, energy-efficient cooling systems, adaptive coolant flow and automated air leakage monitoring, all aimed at improving resource efficiency and lowering operating costs.

With the CTX 450 4A, DMG MORI strengthens its universal turning portfolio by offering a compact yet powerful solution for six-sided complete machining, combining flexibility, precision and sustainability in a single integrated platform.