Dillon Soft Jaws Enhance Precision and Longevity in Workholding Applications!

By Ashutosh Arora

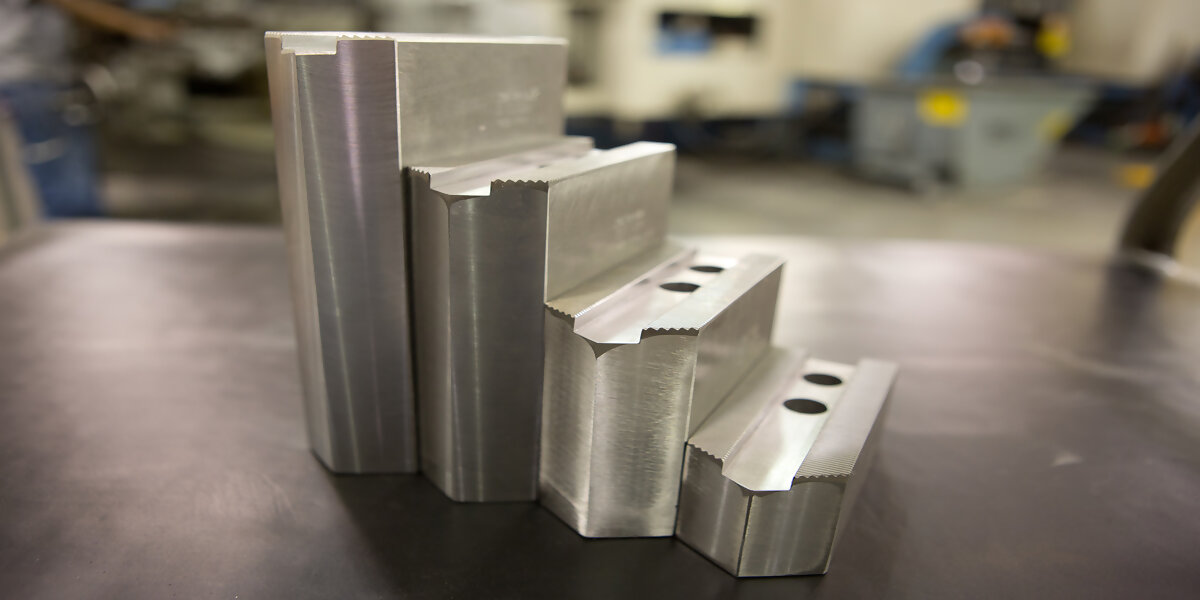

Dillon Manufacturing’s soft jaws are engineered to deliver superior concentricity, chuck balance, and extended jaw life, making them an essential tool for accurate and efficient workholding. These jaws serve as standard components for CNC or manual chuck operations, especially when dealing with turned or bored parts. Dillon’s design improvements ensure that these soft jaws provide reliable performance in demanding industrial applications.

Dillon’s soft jaws feature a milled surface on the jaw end of the blanks, which acts as a convenient locating feature that accelerates setups. This milled surface, located opposite the clamping surface, also serves as a datum for the precise positioning of counter-bored holes and serrations on the jaws. As a result, each set of Dillon chuck jaws is manufactured with exact dimensional matching, ensuring higher accuracy and better overall performance.

These advanced features not only speed up setup times but also improve concentricity—the uniformity of the workpiece rotation—helping achieve better chuck balance during machining. This precision reduces the likelihood of part misalignment, which is crucial for second-operation finishing tasks, such as shaft, gear blank, and bearing production. The accuracy of the jaws also contributes to longer jaw life, as they experience less wear due to better alignment and distribution of forces.

Dillon’s soft jaws are available in a variety of materials to suit different project needs, including 1018 steel, 6061 aluminum, 4140, 8620, A2, brass, delrin, and stainless steel. This wide selection ensures that users can choose the ideal material for their specific applications, whether they are working with heavy-duty metal parts or lightweight components. These jaws are particularly well-suited for second-operation finishing work in applications such as turning, boring, and machining for industries like automotive, aerospace, and manufacturing.

The improved chuck balance, precision, and durability of Dillon’s soft jaws translate directly into time savings and cost reduction for manufacturers. By reducing the need for frequent jaw replacements and minimizing setup errors, companies can see increased throughput and higher-quality finished parts. This makes Dillon’s soft jaws an excellent choice for those looking to enhance the accuracy and reliability of their CNC and manual chucking operations.

In summary, Dillon Manufacturing’s soft jaws offer significant improvements in setup speed, concentricity, balance, and jaw life. Their ability to perform consistently in high-precision applications makes them a reliable choice for a range of machining and finishing operations. Whether in turning or boring tasks, these soft jaws ensure superior performance for manufacturers aiming for precision and efficiency.