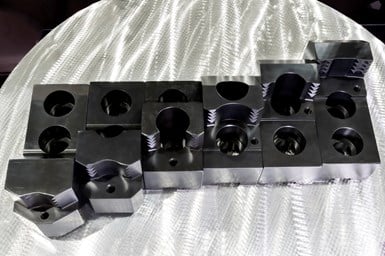

Dillon Manufacturing Claw Jaws Improve Clamping Performance and Reduce Turning Cycle Times!

Dillon Manufacturing Inc. has introduced its claw jaws as a high-performance workholding solution designed to help machining operations achieve stronger clamping, more aggressive cutting parameters, and shorter cycle times in turning applications. Engineered specifically for productivity-driven environments, these jaws address one of the most critical factors in turning operations: maintaining secure, consistent workpiece grip under high cutting forces.

At the core of Dillon’s claw jaw design is an optimized balance of contour, mass distribution, center of gravity, and force transmission. Rather than relying solely on higher chuck pressure, the claw geometry is engineered to translate available clamping force more efficiently into the workpiece. This allows machinists to take heavier cuts and increase feed rates with confidence, without compromising part stability or surface integrity. The result is faster cycle times and improved throughput, particularly in high-volume or demanding turning applications.

The claw jaws are designed to deliver increased clamping pressure on both outside diameter (OD) and inside diameter (ID) gripping applications. This versatility makes them suitable for a wide range of parts, from solid bar stock to thin-walled or difficult-to-hold components. By maintaining strong, consistent grip across different part geometries, the jaws help reduce part movement, vibration, and chatter—factors that can negatively impact tool life, dimensional accuracy, and surface finish.

Compatibility is another key advantage of Dillon’s claw jaws. They are designed to work with most standard chuck systems, allowing shops to upgrade their workholding performance without investing in entirely new chucking equipment. Clamping depth can be adjusted through the use of workpiece stops, giving operators additional flexibility to accommodate varying part lengths and machining requirements. This adaptability makes the jaws well-suited for job shops as well as production environments where part mix and setup efficiency are critical.

Dillon Manufacturing offers the claw jaws in a wide range of standard sizes to support common turning applications. For more specialized requirements, the company also provides custom jaw designs tailored to specific parts or processes. Notably, these custom solutions are offered without engineering fees, reducing barriers for shops that need application-specific workholding while keeping overall tooling costs under control.

Durability is a central consideration in the design and material selection of the claw jaws. They are manufactured from 8620 steel, a material known for its toughness, wear resistance, and suitability for demanding mechanical applications. This construction supports long service life even in high-pressure clamping and aggressive cutting conditions, helping shops reduce replacement frequency and maintain consistent performance over time.

Manufactured in the United States, Dillon’s claw jaws are positioned as a reliable, readily available workholding solution for shops focused on productivity and cost efficiency. Fast delivery, combined with robust design and application flexibility, allows manufacturers to respond quickly to production demands while minimizing downtime associated with tooling changes or workholding limitations.

Overall, Dillon Manufacturing’s claw jaws provide a practical path to higher machining efficiency. By improving clamping effectiveness and stability, they enable faster cutting strategies, reduced cycle times, and lower tooling costs—making them a valuable addition for turning operations seeking measurable gains in productivity and process reliability.