Datanomix Enhances Delivery Track Software for Real-Time Predictive Insights and Universal ERP Connectivity!

By Ashutosh Arora

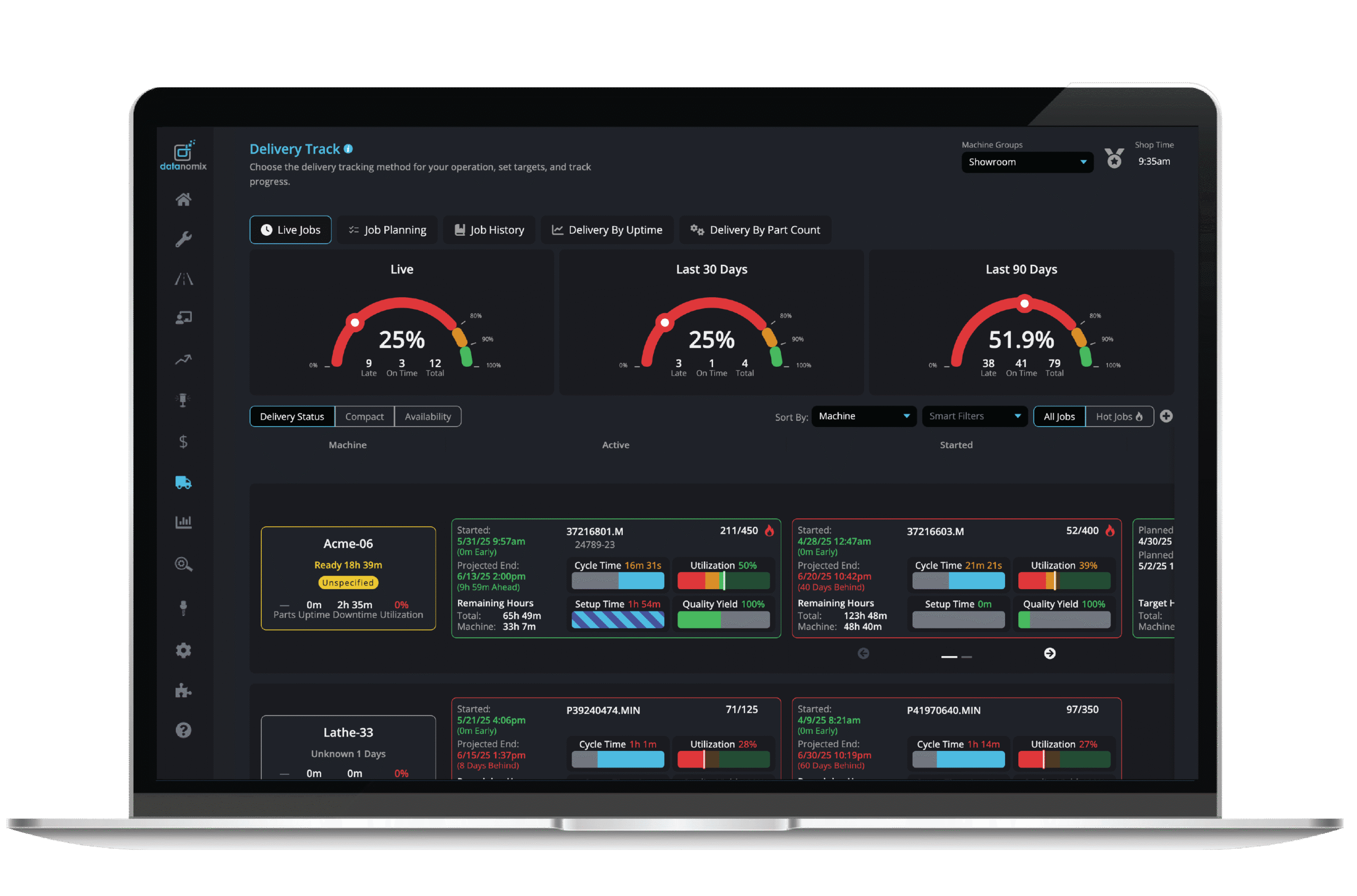

Datanomix has recently upgraded its Delivery Track software to offer a more comprehensive solution for manufacturers seeking to improve on-time delivery (OTD), scheduling accuracy, and overall operational efficiency. With the inclusion of predictive job completion insights, smart job placement recommendations, and universal ERP connectivity, Delivery Track is designed to provide a unified, real-time view of job status, helping manufacturers stay on top of production goals and streamline their processes.

Delivery Track was developed to address a common challenge in manufacturing: determining the exact timeline for job completion. The software connects live machine data with ERP-driven scheduling to offer a clear, real-time snapshot of job progress, showing precisely when jobs will be done and what comes next. This integration allows teams across the shop to have access to the same data, reducing confusion and improving communication between departments.

One of the key features of Delivery Track is its ability to provide manufacturers with real-time insights into job performance. The software now includes a Universal ERP Connector, which enables seamless integration with any ERP system. This update allows manufacturers to pull in work orders, quantities, and due dates automatically, eliminating the need for manual data entry and ensuring that job tracking is always aligned with real-time performance on the shop floor. As a result, manufacturers can stay on top of production schedules and meet deadlines with confidence.

The upgraded Delivery Track software also features enhanced analytics that provide key metrics such as overall equipment effectiveness (OEE) and on-time delivery by customer, part number, and part family. This allows manufacturers to monitor performance and make data-driven decisions to improve efficiency and reduce risks. Additionally, the software offers live job monitoring and projected completion times, so manufacturers can see how jobs are progressing and identify potential issues before they impact delivery.

Another critical capability is the Job History Scorecards feature, which allows manufacturers to review past performance by customer, part number, work order, or timeframe. This feature helps pinpoint wins and losses in previous jobs, enabling manufacturers to learn from past experiences and refine their processes for future jobs. The Machine Availability Planner also helps manufacturers identify the best machine for upcoming jobs based on availability and performance forecasts, ensuring that resources are used efficiently and jobs are completed on time.

The universal ERP connectivity also extends beyond just data integration. It helps align different departments—engineering, operations, planning, and sales—by providing everyone with the same up-to-date information. With this integration, all teams can plan smarter, improve coordination, and work towards shared production goals. This synchronized approach is crucial for improving operational flow and minimizing delays in the production process.

According to Greg McHale, Datanomix’s founder and CEO, “Delivery Track is about more than just schedules — it’s about creating a single source of truth for your shop. By connecting your ERP to real-time machine data, we’re giving manufacturers a complete, accurate picture of what’s going on and what needs to happen next. That’s how great teams stay on track and deliver with confidence.”

With these new updates, Delivery Track empowers manufacturers to make informed decisions, optimize production processes, and ensure timely delivery—all while minimizing manual effort. This software solution not only provides real-time tracking but also enhances overall operational efficiency by seamlessly connecting machine data with ERP systems, helping manufacturers improve accuracy, reduce errors, and maintain a steady flow of work on the shop floor.