Danfoss Unveils Next-Generation AxisPro® Valve, Bringing Intelligent Hydraulics to a Wider Industrial Landscape!

By Ashutosh Arora

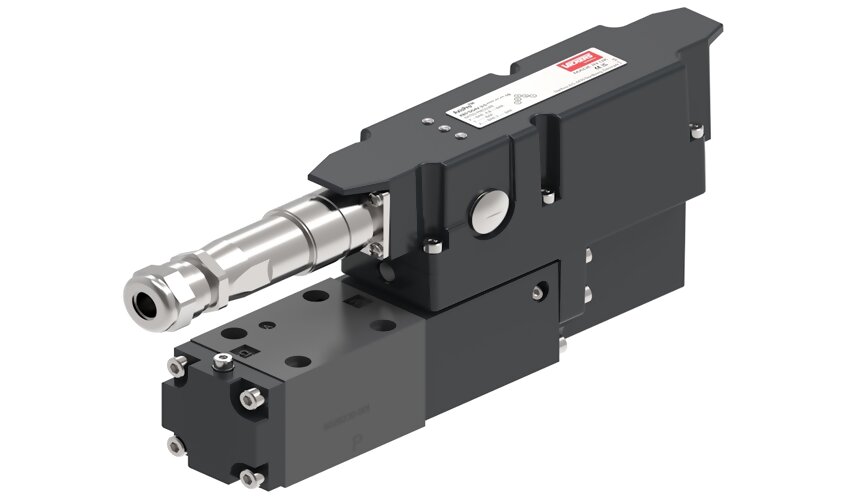

Danfoss Power Solutions has introduced the next-generation Level 1 AxisPro® proportional valve, a major breakthrough designed to make intelligent hydraulic control more accessible across industrial applications. With this launch, Danfoss completes the Vickers by Danfoss portfolio of servo-performance, software-configurable proportional valves—bringing advanced precision, connectivity, and reliability to industries that demand high-performance motion control.

At the core of the upgraded AxisPro is a state-of-the-art digital amplifier paired with seamless compatibility across leading industrial communication networks. The new valve architecture supports Profinet®, EtherCAT®, Ethernet/IP®, and CANopen®, enabling effortless integration into modern automated systems. This connectivity not only improves tuning accuracy and motion control but also provides engineers with richer data, deeper insights, and more responsive system behavior.

Accompanying the valve’s release is Pro-FX™ Configure v2, the redesigned configuration and tuning software that enhances user experience with an intuitive interface and streamlined setup process. The software allows engineers to fine-tune parameters in real time, significantly reducing commissioning time while maximizing system performance. This combination of advanced hardware and smart software marks a major leap forward in hydraulic intelligence.

According to Gary Wei, Global Product Management Director for Motion Controls in Danfoss Power Solutions’ Industrial Division, the upgrade represents a complete reinvention: “This is not just a refresh—it’s a complete transformation. With a digital amplifier and full support for leading network protocols, our next-generation Level 1 AxisPro valves are smarter, faster, and fully connected. We’ve optimized the design and performance while making the technology more accessible to a broader range of users.”

The new AxisPro valve family introduces several performance enhancements. Flow linearization ensures stable, predictable flow across operating conditions—critical for precision applications like presses, machine tools, and advanced factory automation systems. Adjustments for dither and deadband eliminate stick-slip behavior and improve smoothness and control accuracy. The valves also deliver category-leading power capacity and an impressive pressure gain of 2.05%, reinforcing their suitability for high-demand environments.

Built for rugged industrial conditions, the next-generation AxisPro features IP65 and IP67 protection ratings and can operate reliably in temperatures up to 70°C (158°F). Optional corrosion resistance and vibration tolerance up to 50g ensure durability even in harsh applications such as primary metal processing, oil and gas operations, pulp and paper plants, plastics and rubber manufacturing, and heavy civil engineering systems.

The expanded AxisPro lineup now includes six models. The single-stage KBSD14 valves are offered in sizes 03 and 05 (NG06 and NG10), while the two-stage KBHD15 valves will be available in sizes 05, 07, 08, and 10 (NG10, NG16, NG25, and NG32) beginning November 2025. Each model is software-configurable and supported by Pro-FX™ Configure v2, enabling engineers to optimize performance for unique load profiles, speed requirements, and operational conditions.

With this next-generation launch, Danfoss is shaping the future of hydraulic control—delivering smarter, more connected, and highly efficient solutions that elevate industrial productivity and reliability worldwide.