Configurable Robotic Bending System Delivers Flexible, High-Efficiency Automation!

By Ashutosh Arora

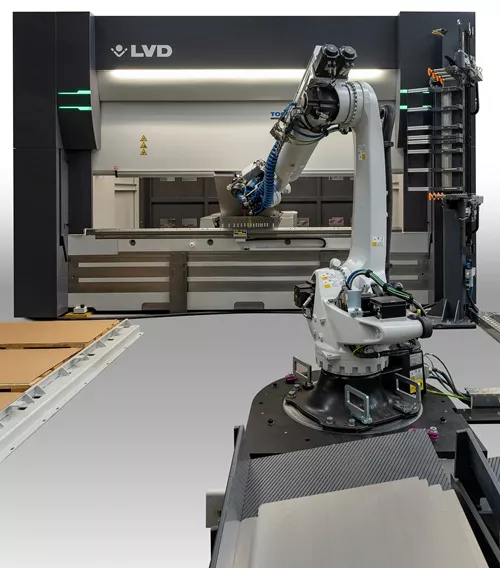

LVD has introduced a new generation of robotic bending systems designed to give fabricators unprecedented flexibility, faster setup, and a more cost-effective path to automation. The new RBS line is built around three scalable platforms, allowing manufacturers to configure a system that precisely matches their part sizes, production flow, and press brake preferences — all while maintaining the accuracy and speed required in modern fabrication environments.

The lineup begins with the RBS 4 platform, which is engineered for smaller components up to 600 x 400 mm and weighing as much as 4 kg. With a maximum profile length of 600 mm, it pairs with compact press brakes offering 1500 or 2000 mm working lengths and force capacities of 40 or 50 tons. For medium-sized parts, LVD offers the RBS 40 platform, supporting components up to 1600 x 1200 mm and 40 kg, along with 2000 mm profile lengths. This platform is compatible with press brakes in 2500 or 3000 mm lengths with ratings of 80, 135, or 220 tons. At the upper end is the RBS 80, built for large components up to 3050 x 1250 mm and 80 kg, featuring compatibility with press brakes from 3000 to 4200 mm and force ratings of 135 or 220 tons. This three-tiered structure ensures that fabricators can select exactly the right combination of robot payload, brake size, and bending capabilities.

Each robotic bending cell is defined through five configurable parameters that guide system design. Users begin by specifying part dimensions, which determine the required robot payload. Next, they select a press brake from LVD’s portfolio — options range from compact electric-drive Dyna-Press models to the advanced ToolCell featuring automatic tool changing. Material flow can then be organized through boxes, pallets, conveyors, or fencing solutions depending on the shop layout and automation level. Gripper selection is fully customizable, with choices that include a universal model, a manual-adjusting version, a magnetic-assisted hybrid, and a heavy-duty option tailored for demanding geometries and weights. This modular approach allows manufacturers to create systems that are optimized for their real-world production mix, whether handling thin stainless brackets or heavy structural components.

Beyond mechanical flexibility, the RBS line integrates advanced software and controls to deliver seamless operation. LVD’s Touch-B interface unifies management of both the robot and the press brake, giving operators a straightforward platform for setup and monitoring. CADMAN-SIM provides automatic programming of bending and robot sequences without the need for manual robot teaching, significantly reducing programming time while ensuring collision-free motion. For manufacturers requiring top-tier precision, an optional Easy-Form Laser system is available to automatically correct bend angles in real time, guaranteeing first-bend accuracy regardless of material variations. When automation isn’t needed, operators can switch to manual press brake control, making the systems well-suited for both short-run and high-volume production environments.

With its configurable design, streamlined workflow tools, and emphasis on adaptability, LVD’s new RBS robotic bending systems are engineered to help fabricators achieve higher throughput, reduced labor demands, and greater process consistency. Whether handling frequent changeovers or running sustained batches, these systems offer a future-ready automation platform built for the evolving demands of metal fabrication.