Complete AM Becomes XJet’s Service Channel Partner for Ceramic and Metal Additive Manufacturing in North America!

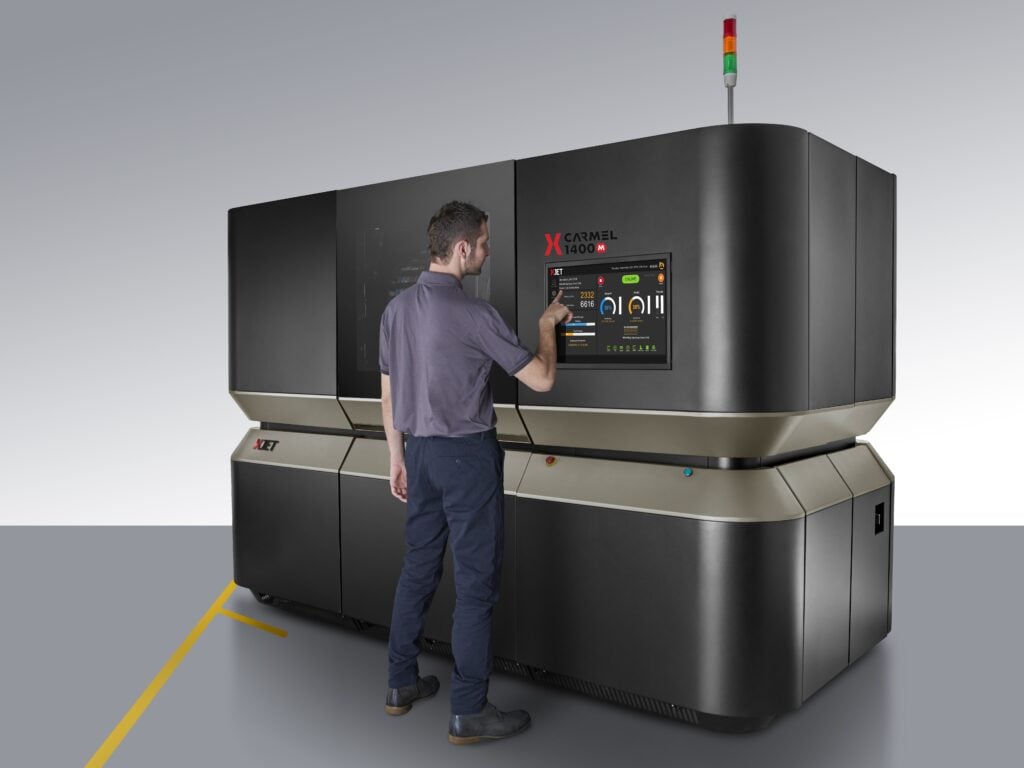

XJet has entered into a strategic partnership with Complete AM, appointing the Illinois-based firm as its full-service channel partner for ceramic and metal additive manufacturing systems across North America. As part of this collaboration, Complete AM will deploy XJet’s Carmel 1400M metal additive manufacturing system and take responsibility for sales, applications support, service, and long-term lifecycle management of XJet’s NanoParticle Jetting (NPJ) technology in the region.

XJet is widely recognized for its proprietary NPJ process, a direct material jetting technology that enables the production of highly complex, high-precision components in metals and advanced ceramics. The technology is particularly valued for its ability to deliver fine surface finishes, intricate internal geometries, and repeatable results suitable for high-value industrial applications. By partnering with Complete AM, XJet strengthens its presence in the North American market while ensuring customers receive localized, hands-on technical expertise and responsive service support.

Based in Schaumburg, Illinois, Complete AM operates as both an additive manufacturing service bureau and a knowledge-driven solutions provider. Co-founded by industry veterans Rory Jackson and Charlie Christensen Phillips, the company brings more than five decades of combined experience in additive manufacturing, machine design, and production workflows. Complete AM’s team includes seasoned mechanical and electronic engineers with deep expertise in equipment manufacturing, process development, and industrial-scale deployment of advanced manufacturing technologies.

Prior to this partnership, Complete AM already supported a broad portfolio of additive manufacturing processes, including FDM, SLA, DLP, LCD, Binder Jetting, LPBF, and SLS. The addition of XJet’s NPJ platform marks Complete AM’s first in-house direct material jetting system, completing its technology ecosystem and expanding its ability to support customers seeking production-ready ceramic and metal AM solutions. This enables the company to offer North American manufacturers access to parts with tight tolerances, complex geometries, and material properties that are difficult to achieve using conventional manufacturing or other additive processes.

A key strength of the partnership lies in Complete AM’s dual role as both a service provider and a reseller. Customers benefit from working with a partner that not only sells and supports XJet systems, but also actively uses the same equipment in real production environments. This hands-on experience allows Complete AM to provide practical guidance on application feasibility, process optimization, workflow design, and long-term system reliability, reducing risk for manufacturers adopting NPJ technology.

From XJet’s perspective, the collaboration enhances customer confidence by ensuring that equipment sales are backed by strong local support, engineering knowledge, and production experience. For Complete AM, the partnership positions the company at the forefront of ceramic and metal direct material jetting in North America, enabling it to serve demanding sectors such as aerospace, medical devices, electronics, and advanced industrial manufacturing.

Overall, the alliance represents a strategic step for both companies, combining XJet’s advanced NPJ technology with Complete AM’s production expertise and service capabilities to accelerate adoption of high-precision ceramic and metal additive manufacturing across North America.