Caron’s DTect-IT Revolutionizes CNC Vibration Monitoring to Safeguard Part Quality and Machine Health!

By Ashutosh Arora

Caron Engineering’s DTect-IT sensor system is redefining how manufacturers approach vibration control in CNC machining, especially in bar feeder operations. This innovative system offers real-time vibration monitoring and automated corrective responses to ensure part quality, machine safety, and operational efficiency remain uncompromised.

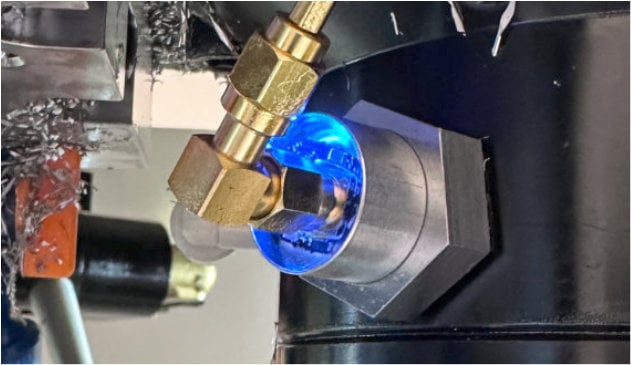

At the core of the DTect-IT system is a high-resolution vibration sensor mounted on the machine’s main spindle. It continuously captures vibration signals during machining and compares them against user-defined thresholds. If these levels are exceeded, the system takes immediate action. One of its standout features is automatic spindle RPM adjustment, which reduces the spindle speed incrementally to bring vibration back within acceptable parameters—helping maintain dimensional accuracy and surface finish. In extreme cases where vibration cannot be mitigated through speed correction, DTect-IT is designed to trigger an emergency stop, preventing potential equipment damage and minimizing scrap generation.

This intelligent system doesn’t stop at monitoring. It empowers users with customizable vibration thresholds, allowing manufacturers to tailor the system’s sensitivity based on specific materials or machining conditions. The built-in data logging and analysis functions provide a window into long-term vibration trends, enabling predictive maintenance and ongoing process optimization.

DTect-IT’s versatility extends beyond bar feeder applications. It functions as a comprehensive sensor analysis platform that supports a wide range of input types including vibration, strain, power, analog, and metrology data. This enables broader machine condition monitoring and real-time reaction capabilities across various machining scenarios.

Designed for seamless integration with a wide variety of CNC lathes and bar feeder systems, DTect-IT enhances part quality by intervening before vibration can cause defects. It also reduces full-bar scrap rates by identifying problematic material early in the process and extends machine life by preventing prolonged exposure to harmful vibration.

The system is also operator-friendly, featuring an intuitive interface that requires minimal training. Its automated corrections significantly reduce the need for constant human intervention, resulting in improved uptime and overall productivity.

In a manufacturing environment where precision, reliability, and uptime are paramount, Caron Engineering’s DTect-IT delivers a proactive, intelligent solution. It protects both your equipment and your bottom line—ushering in a smarter, more resilient approach to CNC machining.