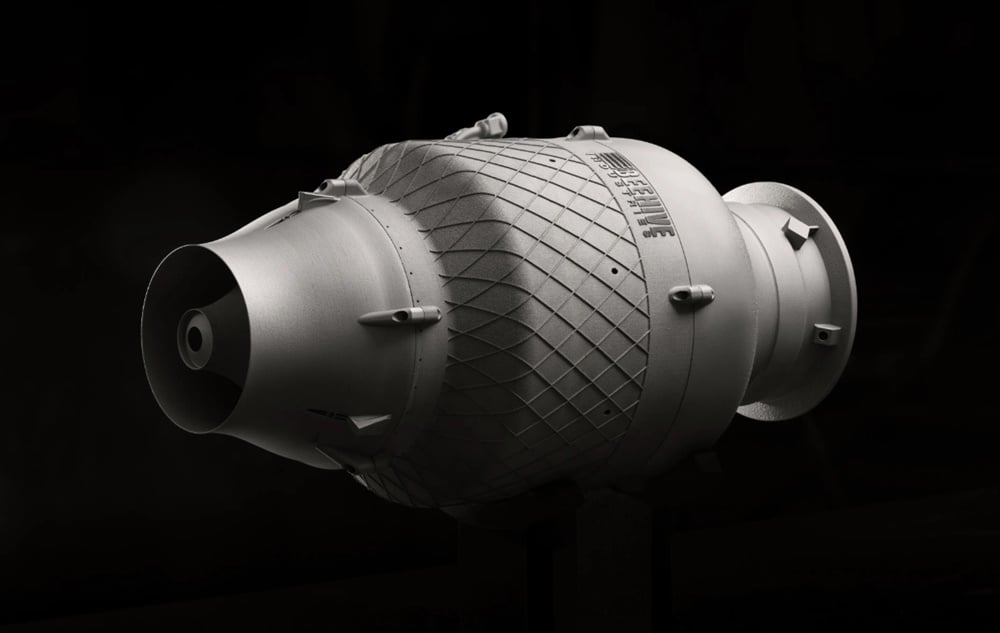

Beehive Industries Completes High-Altitude Testing of 3D-Printed Frenzy Engine, Moves Closer to Flight Readiness!

Beehive Industries has successfully completed high-altitude testing of its 200-pound-force Frenzy engine, marking a major milestone in the rapid development of next-generation propulsion systems for uncrewed aerial defense applications. Conducted at a government test facility in Ohio, the campaign validates the engine’s performance across the full flight envelope and confirms readiness for flight testing scheduled for the first quarter of 2026.

The completion of altitude testing keeps the Frenzy program on schedule and underscores Beehive’s ability to move from concept to validated performance in an exceptionally compressed timeframe. With altitude testing now complete, the company is preparing to scale production to meet rising customer demand while advancing toward flight integration.

According to David Kimball, the milestone confirms that Frenzy is ready for the next phase of development. He noted that in less than a year, the program progressed from initial concept to proven high-altitude operation, achieved ahead of schedule due to an intensely focused and cross-functional development approach. With the engine now deemed flight-ready, Beehive is aligning its production systems to scale in parallel with upcoming flight activities.

The altitude test campaign followed a year of rapid progress for the Frenzy program. In September, Beehive reported the successful completion of ground testing on six engines within just four months. Building on that achievement, two prototype Frenzy engines were delivered on schedule to a government testing facility in Ohio in October, where they underwent a comprehensive series of high-altitude tests. These evaluations assessed performance, ignition reliability at altitude, operability, and durability under demanding conditions.

Test results met or exceeded stringent U.S. Air Force requirements, validating the disruptive potential of the Frenzy engine architecture. During the campaign, the engines demonstrated reliable ignition and stable operation across the full flight envelope, rapid acceleration from light-off to full engine speed, turbine temperatures and thrust-specific fuel consumption better than predicted, and hardware condition described as “like new” after mission-life-equivalent runtime. These outcomes confirm both the robustness of the design and the durability of the hardware under operationally relevant conditions.

Central to these achievements is Beehive’s additive-first manufacturing strategy, which relies heavily on advanced metal additive manufacturing to simplify designs, reduce part counts, and accelerate iteration cycles. This approach allows Beehive to compress traditional aerospace propulsion development timelines from years to months while delivering competitive cost, performance, and scalability. By tightly integrating design, manufacturing, and testing, the company is able to move quickly through iterative improvements without sacrificing reliability or performance.

Kimball emphasized that the test campaign not only validates the engine itself, but also Beehive’s development model. Each milestone reinforces confidence in the Frenzy architecture and the company’s ability to execute on aggressive schedules while meeting defense-grade requirements. The focus, he noted, is not just speed, but ensuring that advanced propulsion technology reaches U.S. warfighters when it is operationally needed.

With flight testing planned for early 2026, Beehive is preparing to integrate the Frenzy engine into its first flight vehicle, representing the final step before entering low-rate initial production. Manufacturing facilities in Denver, Cincinnati, and Knoxville are already ramping capacity in anticipation of future demand.

The Frenzy program builds on a $12.46 million contract awarded in October 2024 by the U.S. Air Force Rapid Sustainment Office in partnership with the University of Dayton Research Institute, and the engine’s formal introduction in December 2024. The Frenzy engine family, spanning 100 to 300 lbf, is designed to power next-generation uncrewed aerial systems with a strong emphasis on efficiency, reliability, and affordability, positioning Beehive Industries as a fast-moving innovator in advanced defense propulsion.