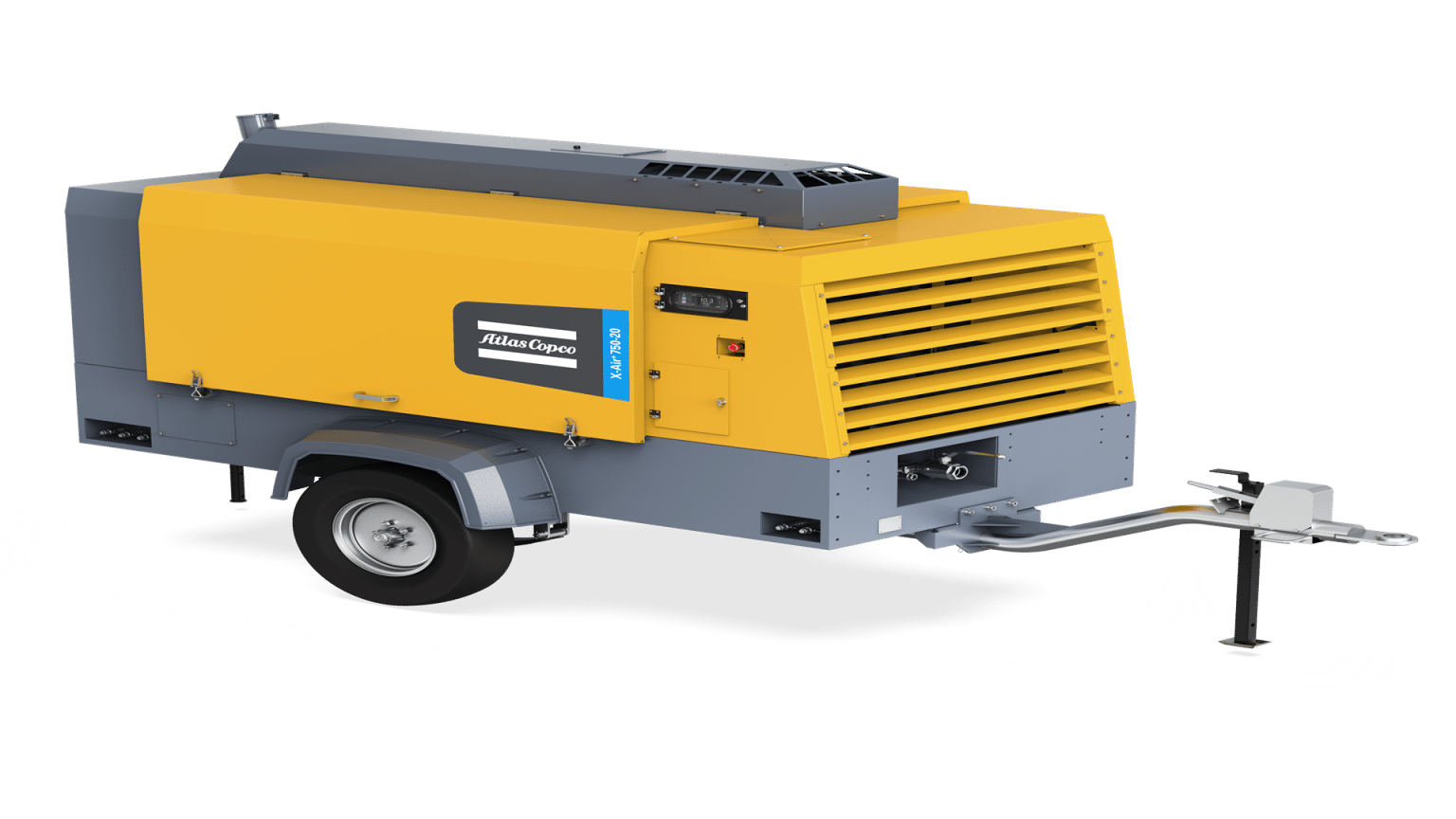

Atlas Copco Introduces X-Air⁺ 750-20 Portable Compressor to Meet Evolving Water Well and Mining Demands!

Atlas Copco has expanded its portable air compressor portfolio with the launch of the X-Air⁺ 750-20, a new high-performance compressor designed to meet the increasingly complex requirements of water well drilling and mining operations. As urbanisation accelerates, noise regulations tighten, and drilling environments become more challenging, operators are demanding equipment that delivers reliable output, operational flexibility, quieter performance, and better fuel efficiency. The X-Air⁺ 750-20 has been engineered specifically to address these shifting expectations across the Indian market.

Water well drilling, mining exploration, tunnelling, and geotechnical applications often involve long operating hours, variable ground conditions, and remote or space-constrained job sites. Atlas Copco has developed the X-Air⁺ 750-20 to deliver sustained, high-pressure airflow while maintaining low noise levels and reduced operating costs. Its compact, foam-insulated canopy significantly lowers sound emissions, making it suitable for use in urban areas, residential zones, and underground or enclosed environments where noise control is critical.

At the core of the compressor is an electronically managed engine that continuously optimises fuel consumption. By intelligently matching engine performance with air demand, the system helps operators reduce fuel usage without sacrificing output or reliability. This focus on efficiency is particularly important as fuel costs continue to rise and contractors look to improve the total cost of ownership of their equipment.

The X-Air⁺ 750-20 is equipped with Atlas Copco’s Xc2004 controller, which provides precise and flexible control over operating parameters. Users can regulate pressure between 175 and 290 psi and adjust airflow from 670 to 740 cfm, allowing the compressor to adapt quickly to changing drilling depths and site conditions. This level of precision supports faster penetration rates, smoother drilling performance, and better overall productivity in demanding applications.

Durability and mobility have also been central to the design. The compressor features a compact, double-layer metal canopy with corrosion protection, ensuring long service life even in harsh outdoor or mining environments. Its robust yet compact construction makes it easier to transport and operate in confined spaces, uneven terrain, or remote locations where access can be challenging.

To further reduce downtime and operating costs, the X-Air⁺ 750-20 offers extended service intervals of up to 1,000 hours. This significantly lowers maintenance frequency and helps maximise equipment availability during critical project phases. In addition, Atlas Copco’s Smart Box remote monitoring system enables real-time tracking of machine performance, operating hours, and service requirements. Predictive maintenance alerts and remote diagnostics support better fleet management and help prevent unplanned breakdowns.

A key requirement in water well and mining operations is the ability to deliver continuous, stable airflow over long drilling cycles. The X-Air⁺ 750-20 meets this need through advanced control technology that automatically adjusts pressure and airflow in response to real-time demand. This ensures uninterrupted performance even in difficult geological conditions, supporting consistent output and operator confidence.

Commenting on the launch, Prasanna Kulkarni, General Manager – Power Technique Customer Center at Atlas Copco (India) Pvt. Ltd., noted that the compressor was developed with a deep understanding of customer challenges. He highlighted that the focus on fuel efficiency, reduced downtime, and dependable performance reflects Atlas Copco’s commitment to supporting drilling and mining professionals across India.

With the introduction of the X-Air⁺ 750-20, Atlas Copco further strengthens its offering of future-ready portable air solutions. The new compressor reinforces the company’s reputation for delivering high productivity, lower lifecycle costs, and reliable performance in critical applications, helping customers operate more efficiently in an increasingly demanding operating environment.