Mitsubishi Materials has introduced an expansion of small diameter end mills to the innovative, high-performance VQ end mill series, designed specifically for stainless steels and other difficult-to-cut materials. Combining cutting-edge geometry with advanced coating technology, the new lineup delivers superior rigidity, wear resistance and chip evacuation for unmatched stability and productivity.

Next-Generation Performance for Challenging Applications

The new VQ3XL, VQ4XL, VQ4XLRB, and VQ2XLB types feature high-rigidity long necks, each size available with a 3xDC, 5xDC and 8xDC reach and designed to prevent tool interference while maintaining exceptional rigidity during deep cutting operations. These tools enable stable, high-efficiency machining across a wide range of demanding materials such as alloy steel, austenitic stainless steels, titanium alloys, cobalt-chromium steel and heat-resistant alloys. Copper alloys can also be capably machined with the new long neck types. They are ideally suited for side and bottom face milling as well as slotting operations. Additionally, the small diameter and long necks of these end mills (under Ø0.6 mm for 3-flute and under Ø1.0 mm for 4-flute types), opens new possibilities for high-precision micro-machining.

Innovative Design Features

The optimized long neck geometry, even at the exceptional 8XDC length, maintains rigidity while minimizing workpiece interference, ensuring stable performance in deep or narrow areas. The micro gash land reinforces corner strength, suppresses chipping and extends tool life. A newly developed end cutting edge chip pocket provides Improved chip evacuation and reduces clogging, particularly for tools with larger corner radii. The multi-flute configuration (3 & 4 flutes) provides faster and more efficient machining than 2-flute tools, even in small diameters below Ø1.0 mm.

SMART MIRACLE Coating

Mitsubishi’s proprietary coating dramatically enhances efficient chip discharge and wear resistance, especially effective on hard-to-cut materials

Enhanced Productivity, Extended Tool Life

By combining high-rigidity tool bodies, advanced edge geometries and state-of-the-art coatings, Mitsubishi Materials continues to push the boundaries of milling performance. The VQ Series empowers manufacturers to achieve exceptional surface finishes, longer tool life and reduced cycle times; all while ensuring reliable performance of very small diameter end mills in the most demanding conditions.

Availability

VQ4XLRB Ø0.4 mm – Ø1.0 mm

VQ3XL / VQ4XL Ø0.2 mm – Ø1.0 mm

VQ2XLB Ø0.2 mm – Ø1.0 mm

All types in with neck lengths 3xDC, 5xDC and 8xDC

——————–

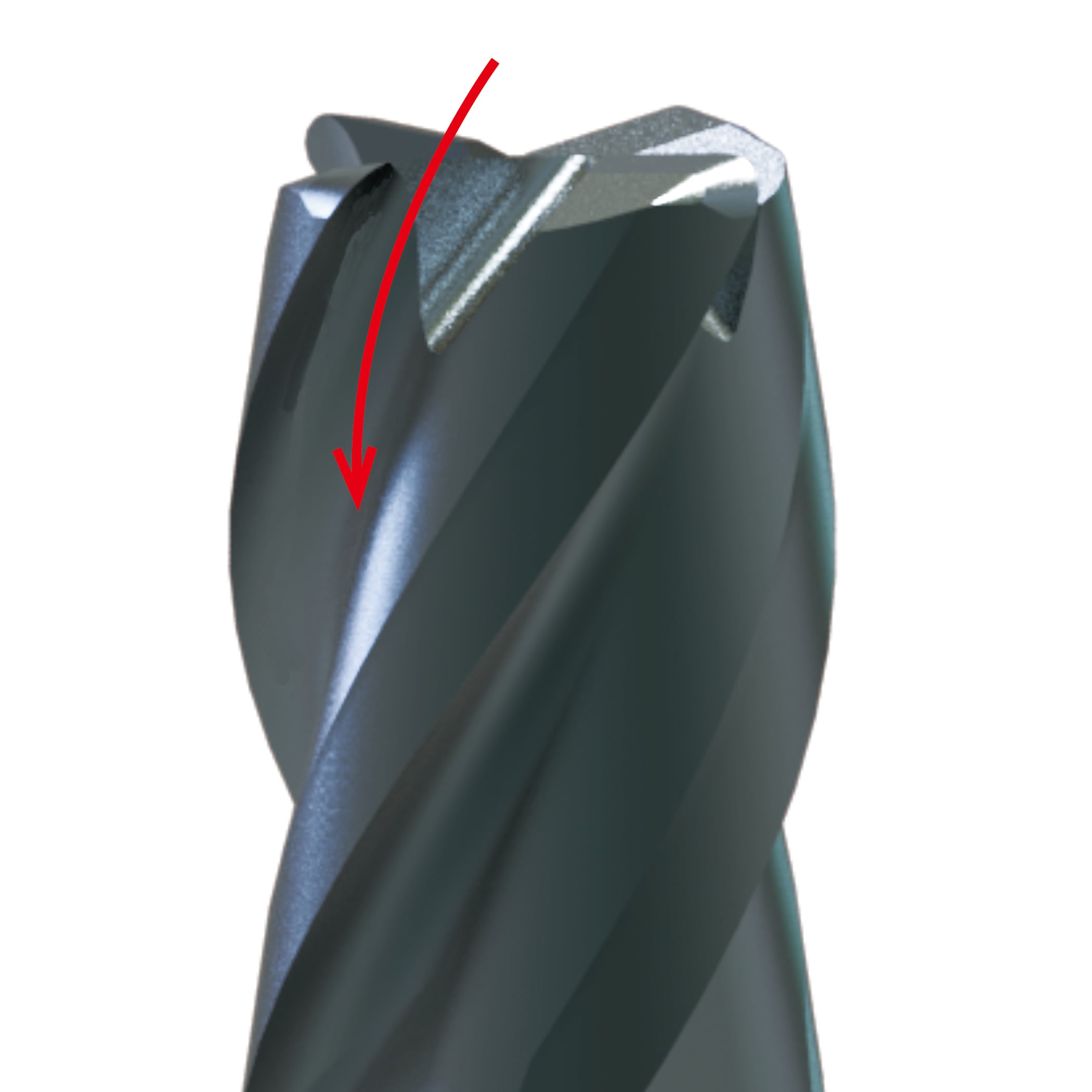

MICRO GASH LAND

Suppresses chipping by increasing the strength of the corners.

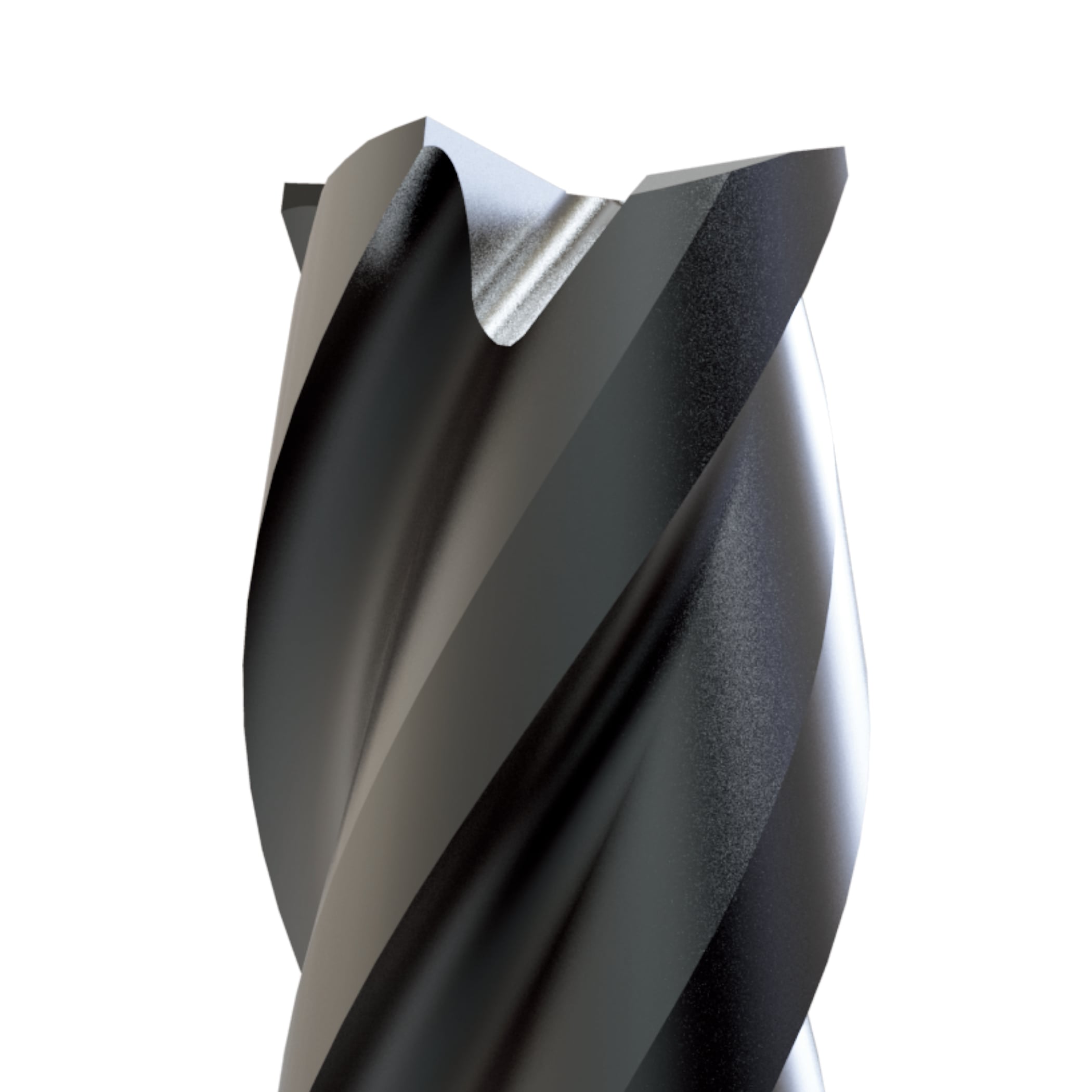

END CUTTING EDGE CHIP POCKET

Optimised geometry of the end cutting edge for excellent chip evacuation.