Mitsubishi Materials has unveiled its BC8200 Series, a cutting-edge innovation in hardened steel machining. This new range of products is setting industry standards with its exceptional capabilities in both continuous and heavy interrupted cutting applications.

The standout BC8220 tool in the BC8200 Series is gaining attention for its impressive crater wear and fracture resistance. This performance is attributed to its advanced Cubic Boron Nitride (CBN) base, enhanced by an innovative coating. These features work together to significantly extend tool life, minimizing downtime for manufacturers.

Designed to tackle a variety of machining challenges, the BC8220 provides consistent, reliable performance. Mitsubishi’s commitment to manufacturing precision is evident in the engineering of this series, which promises to streamline processes and improve efficiency for industrial users.

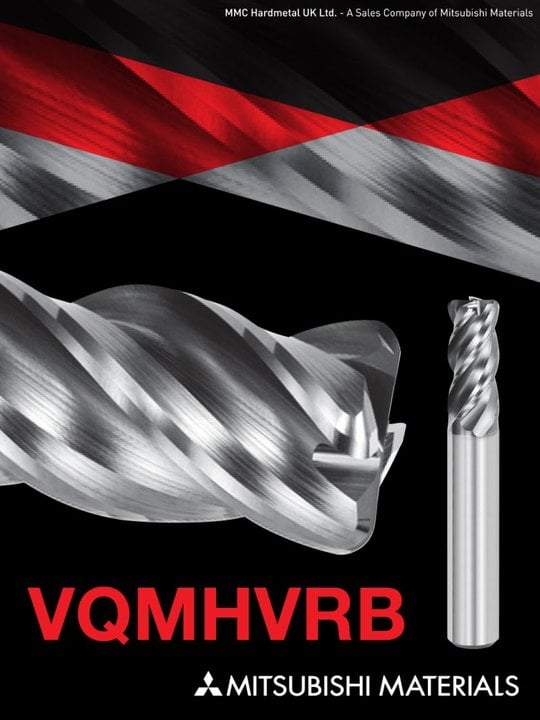

MMC Hardmetal UK Ltd, a subsidiary of Mitsubishi Materials, plays a pivotal role in distributing this cutting-edge tooling technology. The series is particularly well-suited for industries that deal with hardened steels, offering a substantial improvement in productivity and cost-effectiveness.

Mitsubishi Materials continues to lead with innovation, catering to the evolving needs of the manufacturing sector. By reducing wear and extending the lifespan of cutting tools, the BC8200 Series represents an important advancement for manufacturers aiming to enhance operational efficiency and reduce expenses.