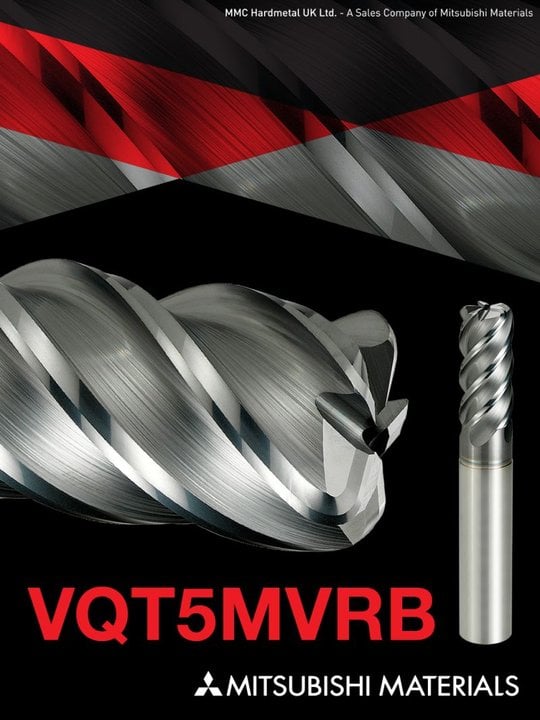

Mitsubishi Materials has introduced the VQT5MVRB, a cutting-edge 5-flute milling tool designed to enhance performance in titanium machining. With its innovative configuration and stable cutting edge, the tool promises to deliver superior rough machining capabilities, meeting the high demands of modern machine shops.

The VQT5MVRB features a coolant-through design, a significant advancement that allows for improved chip evacuation, directly impacting tool life and performance. This improvement not only enhances efficiency but also ensures reliability, crucial for operations dealing with tough materials like titanium.

Manufacturing industries require tools that can withstand challenging conditions, and Mitsubishi Materials’ latest offering is tailored to meet these needs. The company has positioned the VQT5MVRB as a perfect fit for facilities focused on efficiency and reliability, reinforcing their commitment to high-performance tooling and precision engineering.

The release of this tool underlines Mitsubishi Materials’ dedication to innovation in the tooling sector, providing solutions that cater to the dynamic requirements of the manufacturing industry. As precision and performance continue to be the cornerstones of machining excellence, the VQT5MVRB offers shops the confidence to tackle titanium with efficiency.

Mitsubishi Materials Corporation, headquartered in Japan, has a long-standing reputation for producing high-quality cutting tools. Their latest introduction reaffirms their position as a leader in the field, continuously providing technological advancements that drive industry standards.

View more news from MMC Hardmetal UK Ltd