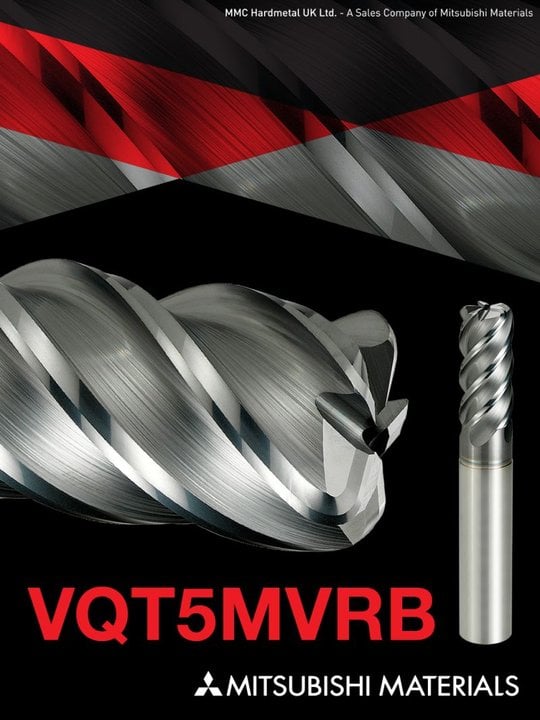

Mitsubishi Materials has introduced the MV1000 Series, a new line of cutting inserts designed to enhance performance in challenging milling conditions. This innovation addresses the common issue of thermal cracking, a frequent cause of insert failure in wet milling applications.

The MV1000 Series boasts extreme thermal shock resistance, offering stability in both dry and wet cutting environments. The advanced coating technology allows these inserts to withstand harsh temperature swings, providing machinists with the ability to maintain productivity under demanding conditions.

Engineered for durability, the MV1000 Series enables operators to extend the life of their tools. By running tools harder and longer, manufacturers can improve efficiency and reduce downtime associated with tool changes due to insert failure. This advancement is expected to deliver a significant increase in machining stability, a critical factor for industries relying on precise and consistent performance.

Mitsubishi Materials has focused on enhancing CNC performance with these milling tools. The MV1000 Series represents the company’s commitment to advancing the manufacturing process through innovation and engineering excellence.

As a key player in the manufacturing sector, Mitsubishi Materials continues to provide cutting-edge solutions for industrial applications globally. Their latest product offerings ensure productivity improvements and cost reductions, reinforcing their reputation as a leader in advanced manufacturing technologies.

View more news from MMC Hardmetal UK Ltd