The staff of Mitutoyo UK will be demonstrating a multitude of new measuring and testing instruments at MACH 2020 (stand number 19-530), including the recently launched MiSTAR 555 CNC Coordinate Measuring Machine. The cost-effective new CMM was designed to provide users with an accurate, reliable means of shop-floor measurement. The robust new MiSTAR 555 operates without the need for compressed air and needs only a domestic electrical supply.

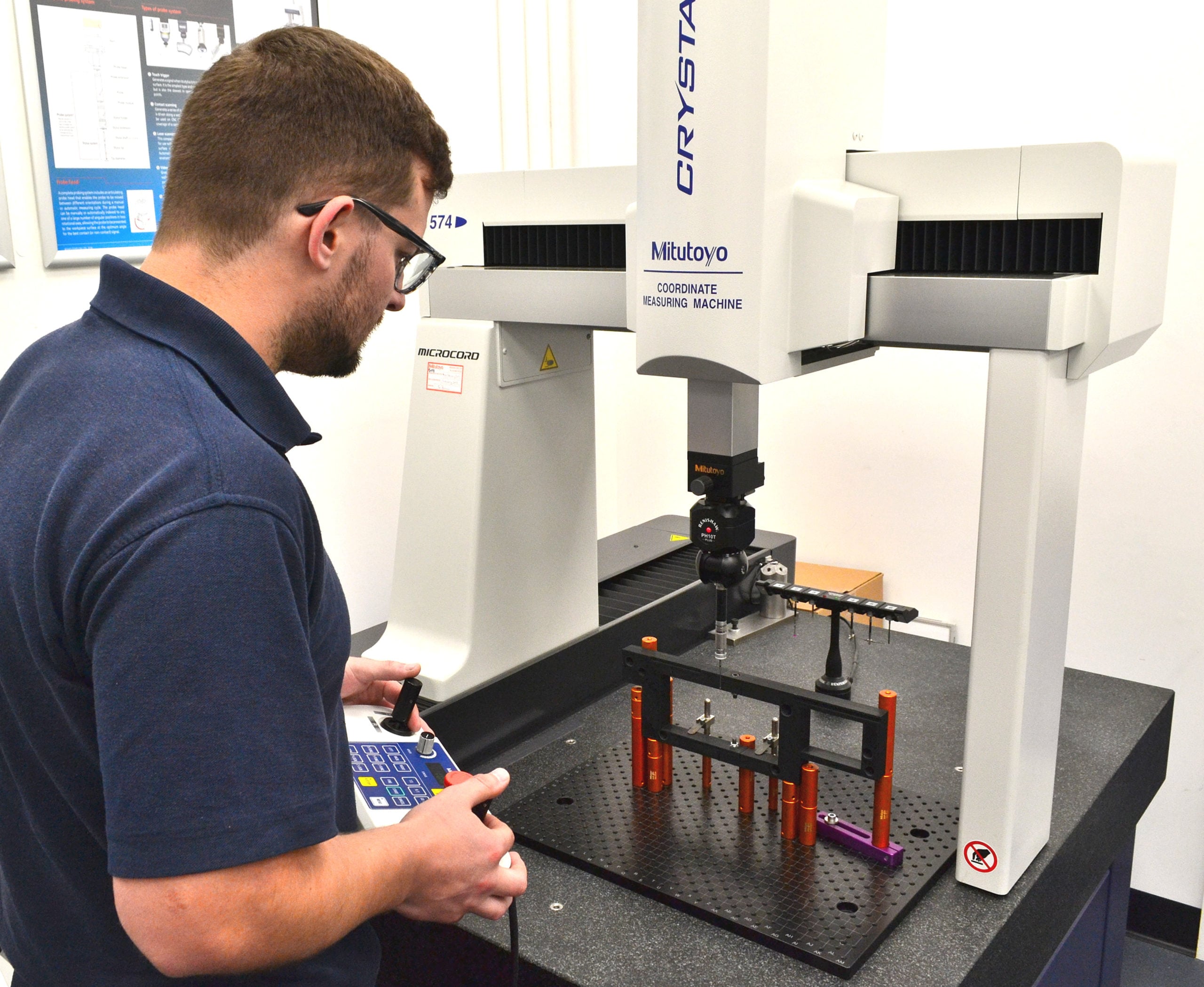

Another exciting addition to Mitutoyo’s comprehensive CMM line-up is the CRYSTA-Apex V series of CNC CMMs. Building on the popularity of previous CRYSTA-Apex CMMs, the advanced new models deliver high-accuracy (1.7 μm), in addition to high-speed and acceleration characteristics.

Also being put through their paces at MACH will be Mitutoyo’s newly developed, high-accuracy, high-resolution QM-Height Gauges with ABSOLUTE linear encoders for position detection.

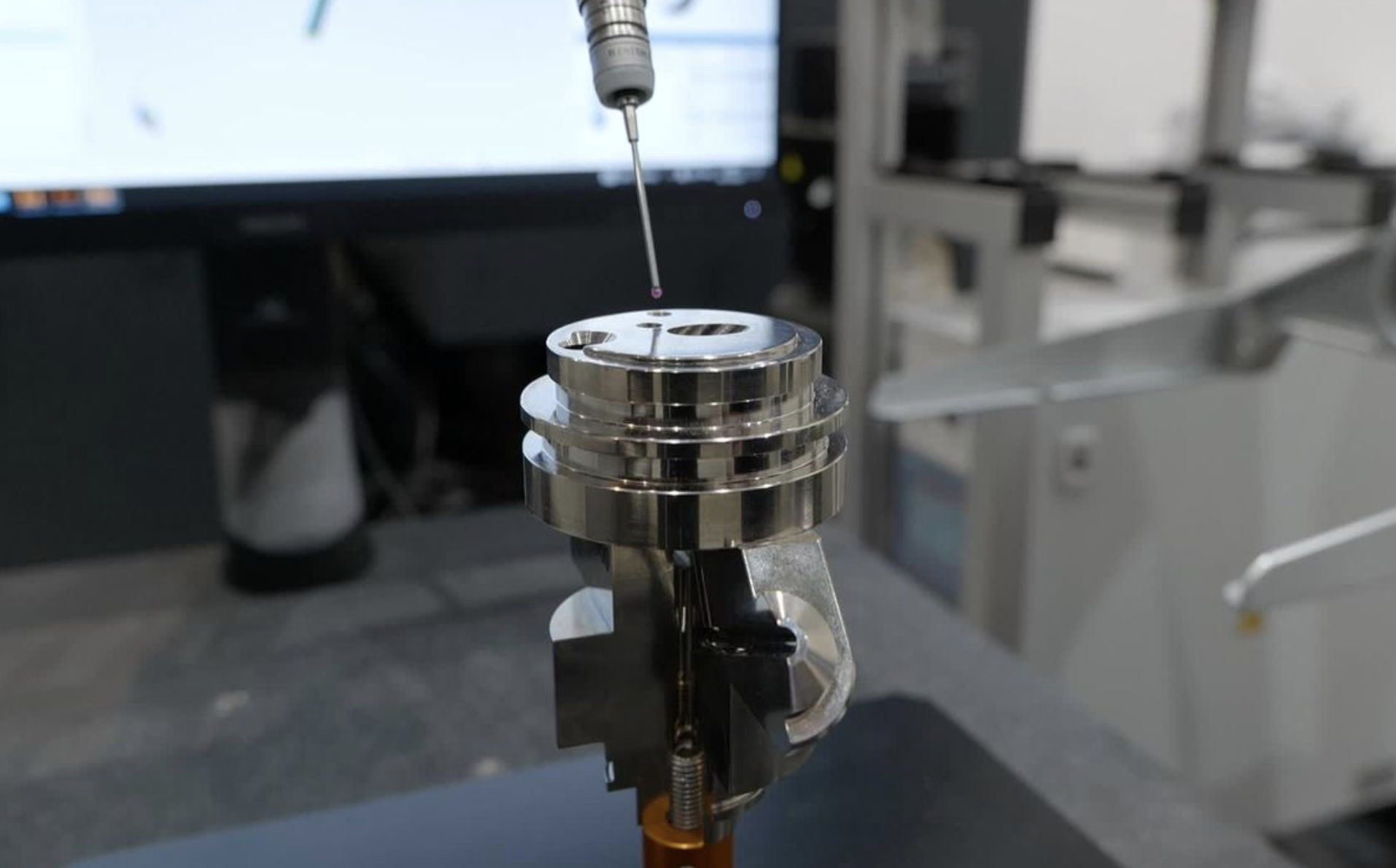

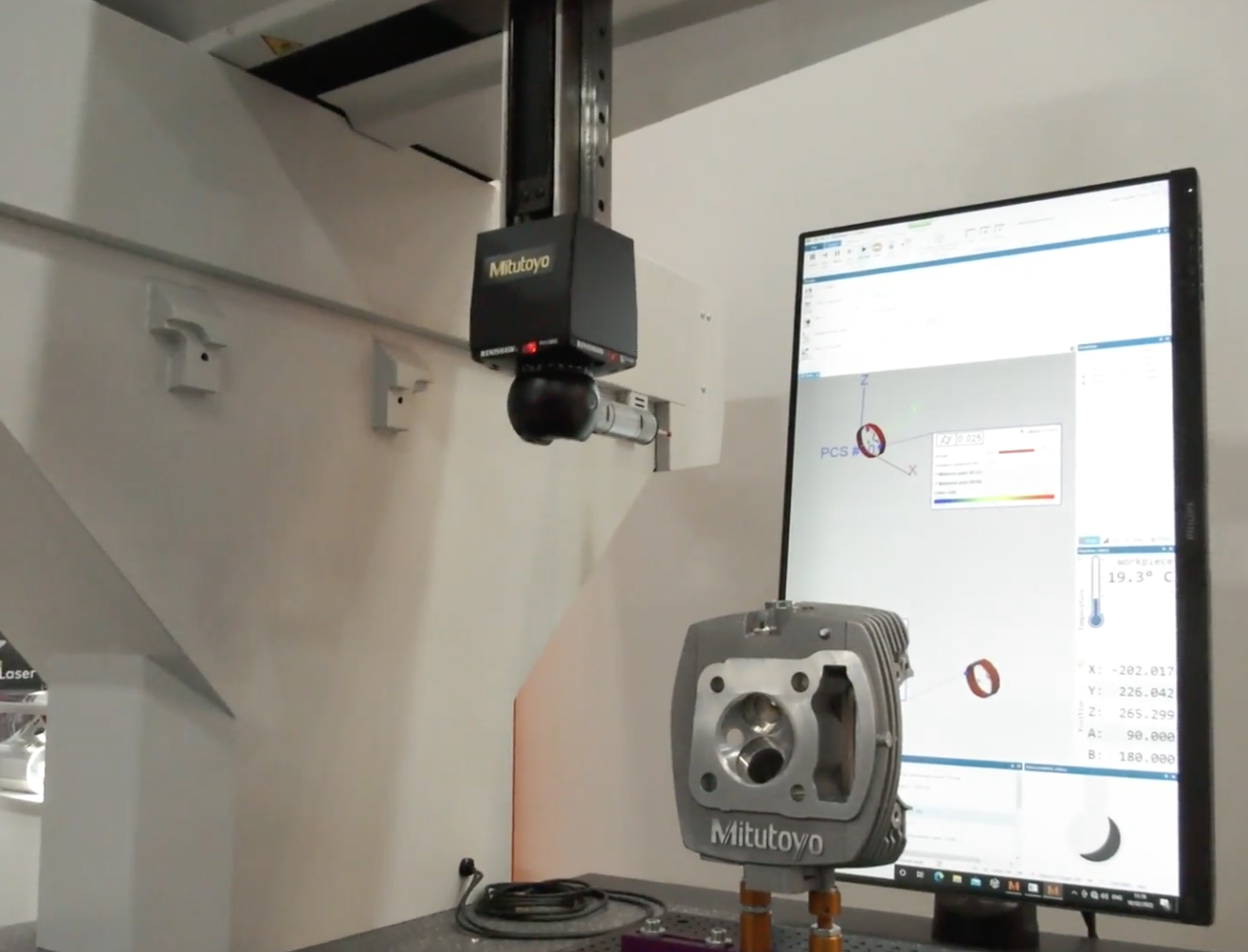

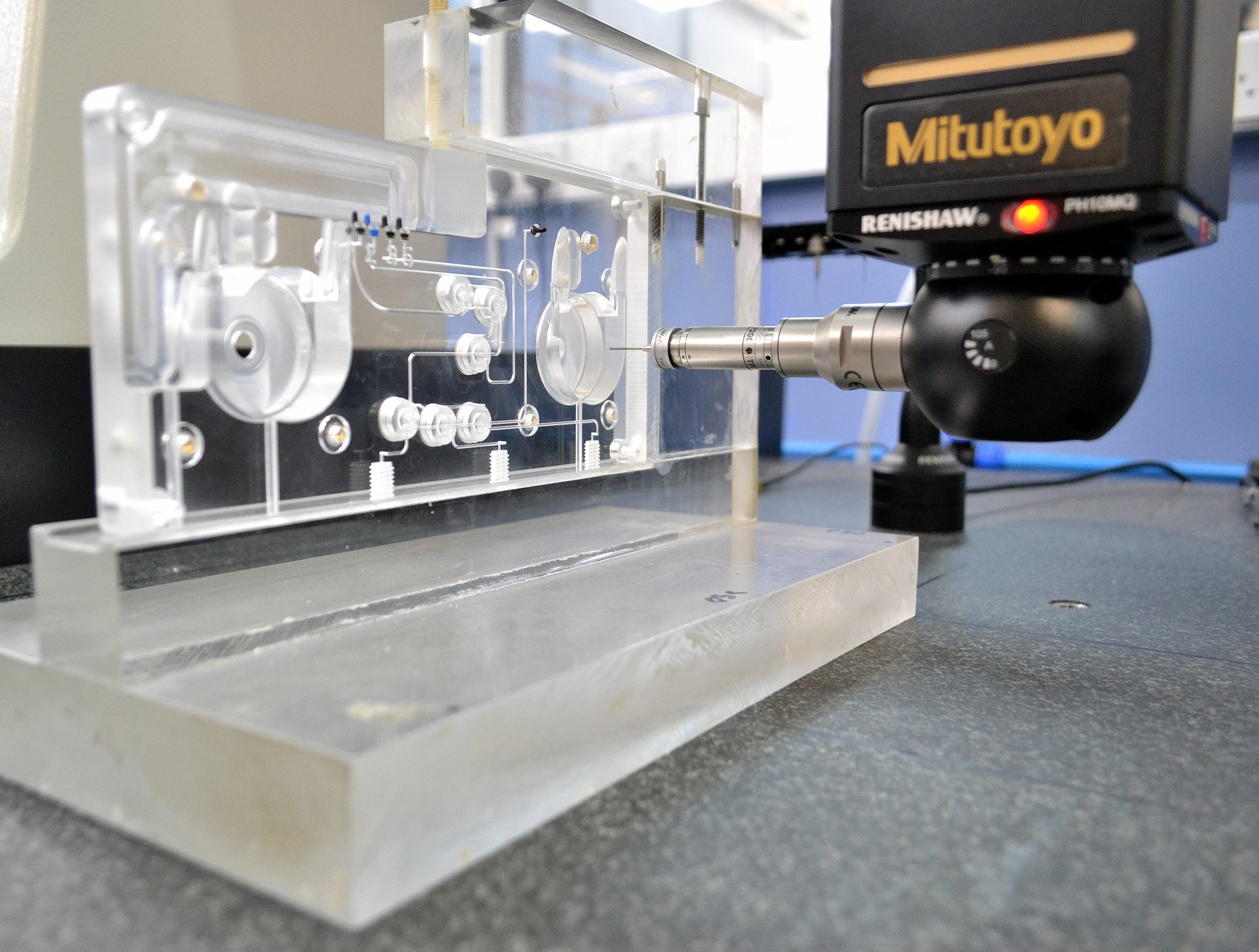

Renowned for its innovative optical measuring devices, Mitutoyo will have 3 recently introduced optical instruments being demonstrated, including the award winning MiSCAN Vision System. The innovative Mitutoyo multi-sensor vision measuring machine combines highly accurate non-contact vision measurements with tactile measuring. The MiSCAN Vision System uses a SP25M touch probe and Mitutoyo’s newly developed MPP-NANO scanning probe that is specifically designed for the high accuracy scanning measurement of minute parts. The system is supported by the MCOSMOS and VISIONPAK-PRO software that offers first-class functionality for both tactile and non-contact measurements.

Demonstrations of the precise new Mitutoyo Formtracer Avant will illustrate the innovative hybrid instrument’s ability to deliver both contour and surface roughness measurements in a single, easy to use unit. Last but not least, Mitutoyo’s new HR-350 Hardness Tester will be proving its ability to provide accurate readings across five different hardness testing methods, rendering it the ideal versatile tool for production, goods inwards inspection and quality control use.