Toyoda offers manufacturers worldwide a large portfolio of machines for different types of applications/machining, including horizontal machining centres, grinders, turning centres and bridge mills.

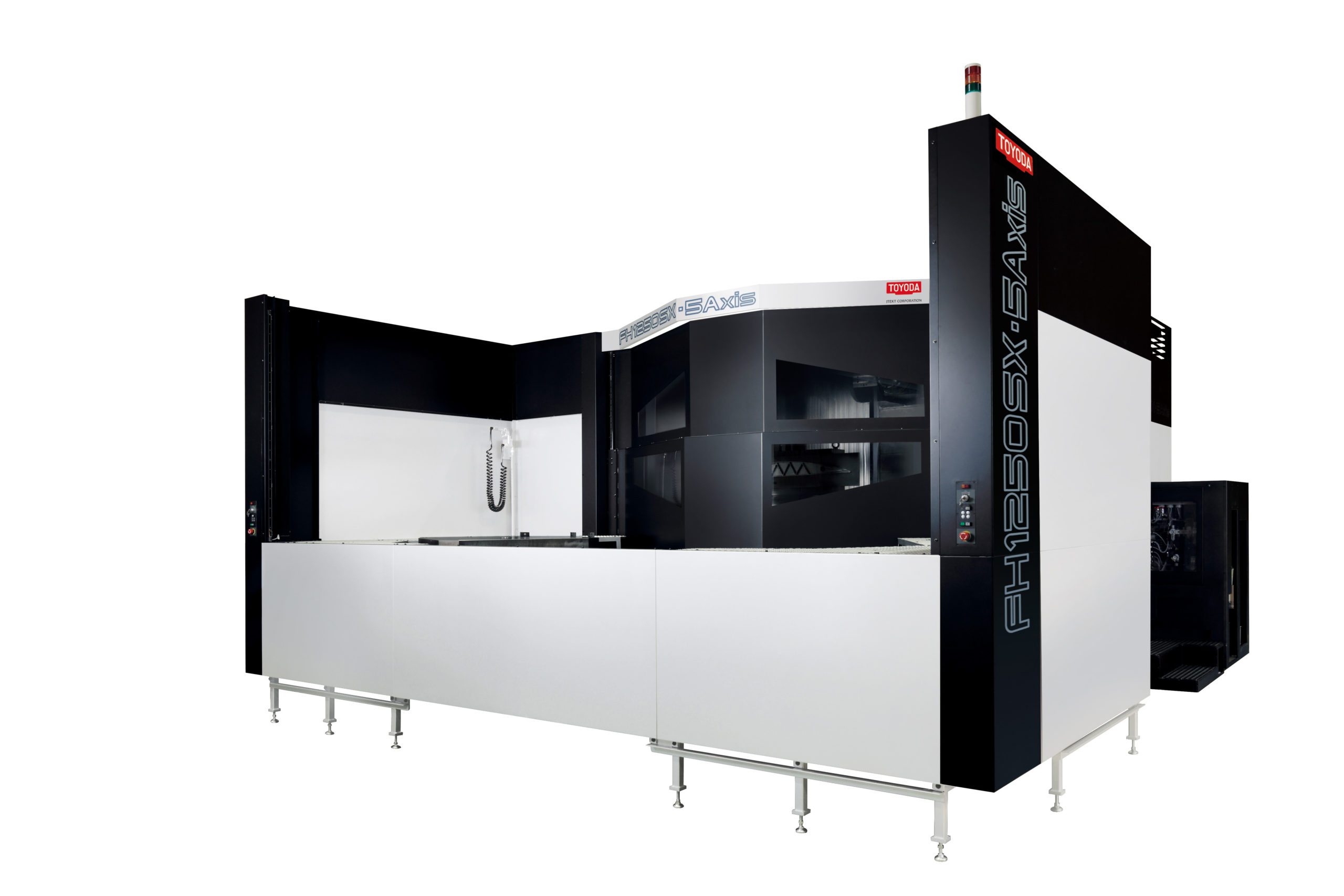

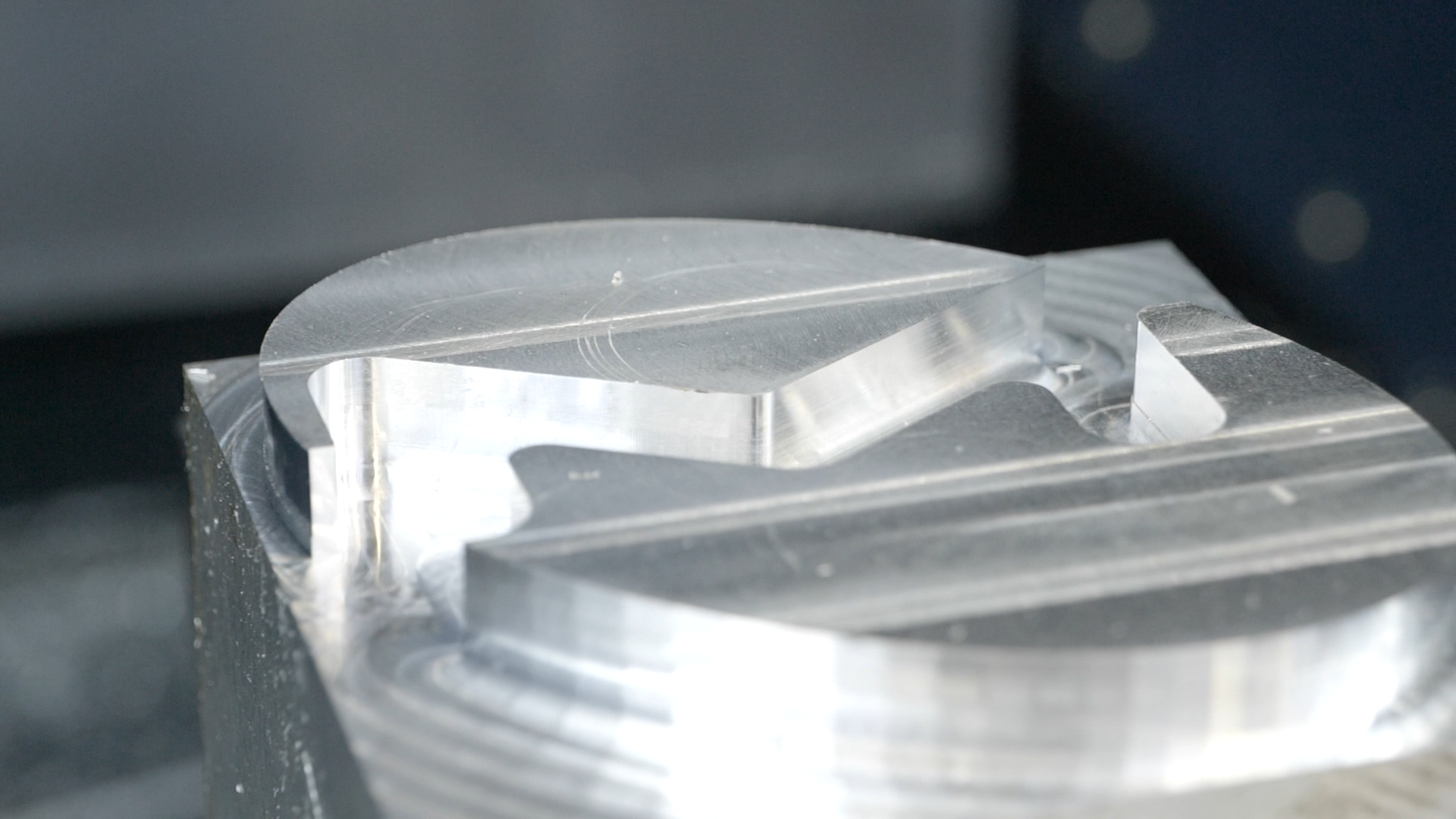

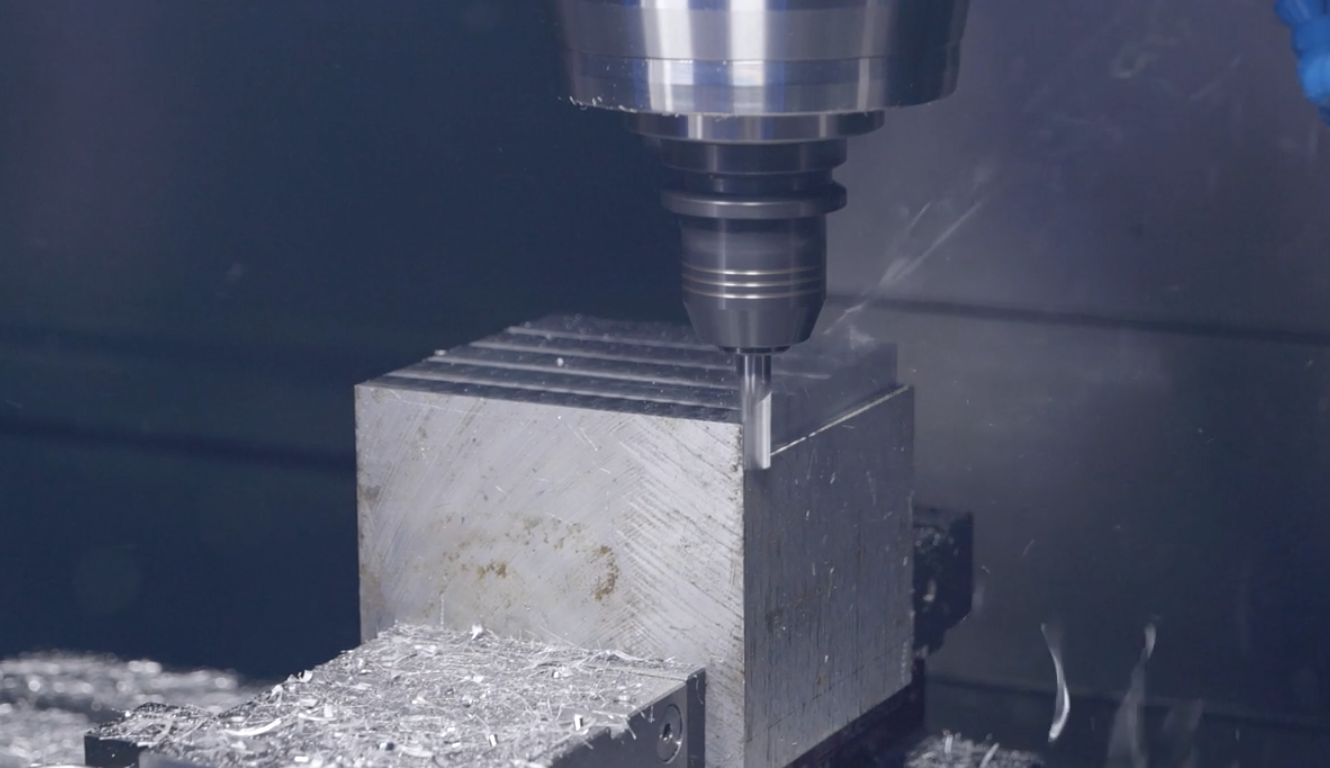

Leader CNC Technologies is proud to offer four of their horizontal machining centres featuring 5-axis capabilities with the advantages of versatility and high precision. Toyoda machines with their revolutionary 5-axis technology, provide the capability to machine complex shapes efficiently in a single set-up, achieve optimal cutting condition and quality surface finishes, increase tool longevity, improve machining accuracy resulting in cost-saving, shorter production times.

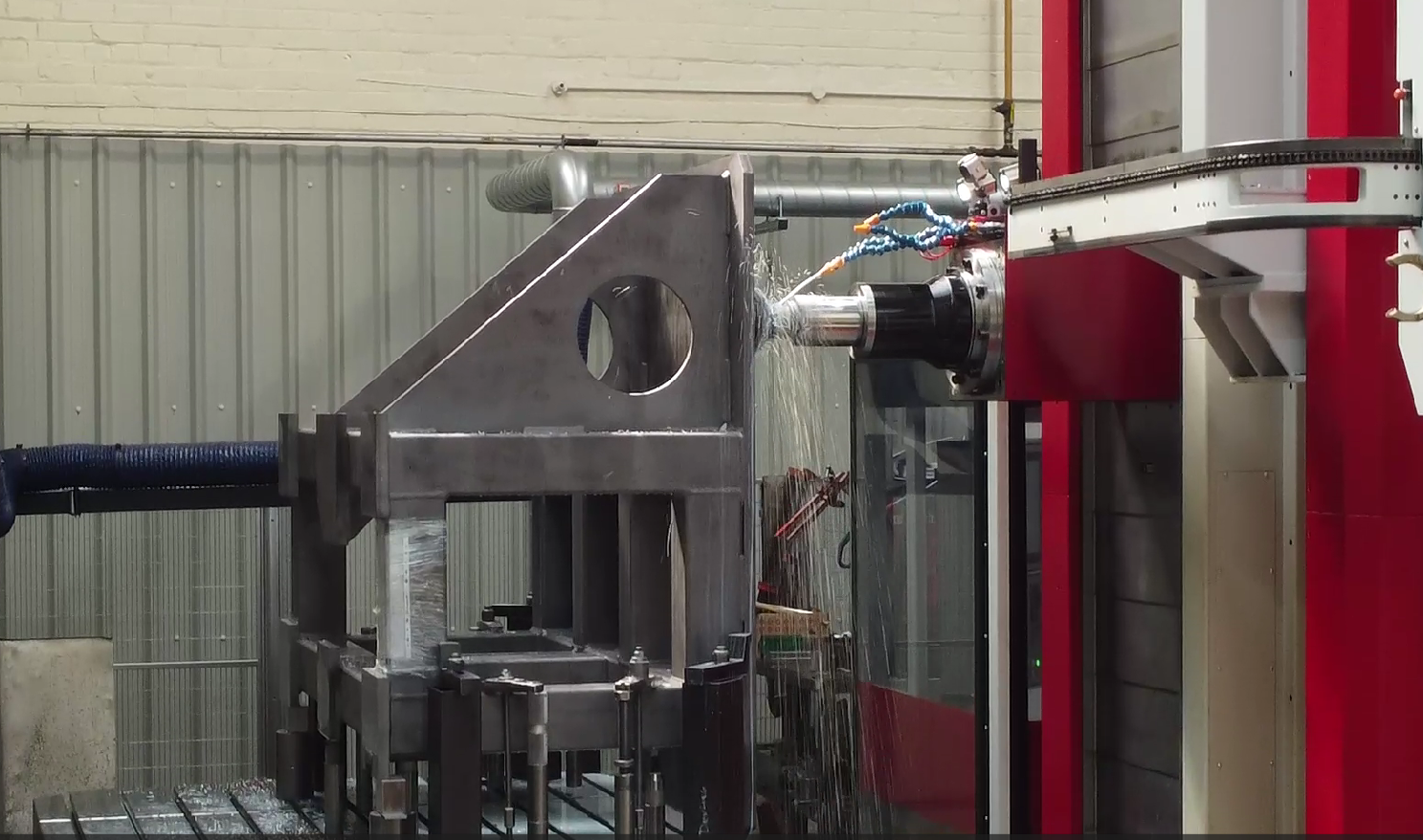

The FH630SX and FH1250SX achieve simultaneous 5-axis machining using tilting/swivel spindles, making large workpieces more easily loaded onto the pallet and, by not indexing the workpiece, ensure maximum rigidity. This has made their machines a top choice for multi-face and five-axis applications in metal cutting industries.

On the smaller machines, the FA800S and FA1050S, five-axis machining is achieved with a trunnion table. Dual-drive mechanisms support the workpieces, while the high-resolution rotary encoders ensure precise positioning during simultaneous five-axis applications. These machines offers a large work envelope and a wide range of tilt angles on the A-axis from — 15° to 100° — to access difficult-to-reach workpiece features.

For more information on the TOYODA range visit – www.leadercnc.co.uk or alternatively follow us on our social media channels below.

Linkedin – www.linkedin.com/company/leader-cnc-technologies

Facebook – www.facebook.com/Leader-CNC-Technologies

Twitter – www.twitter.com/LeaderCNCTech