We are pleased to announce that Takumi have released two new vertical machining centres to enhance their ever-growing portfolio of products and give users the opportunity to select the best and cost-effective machine for their application.

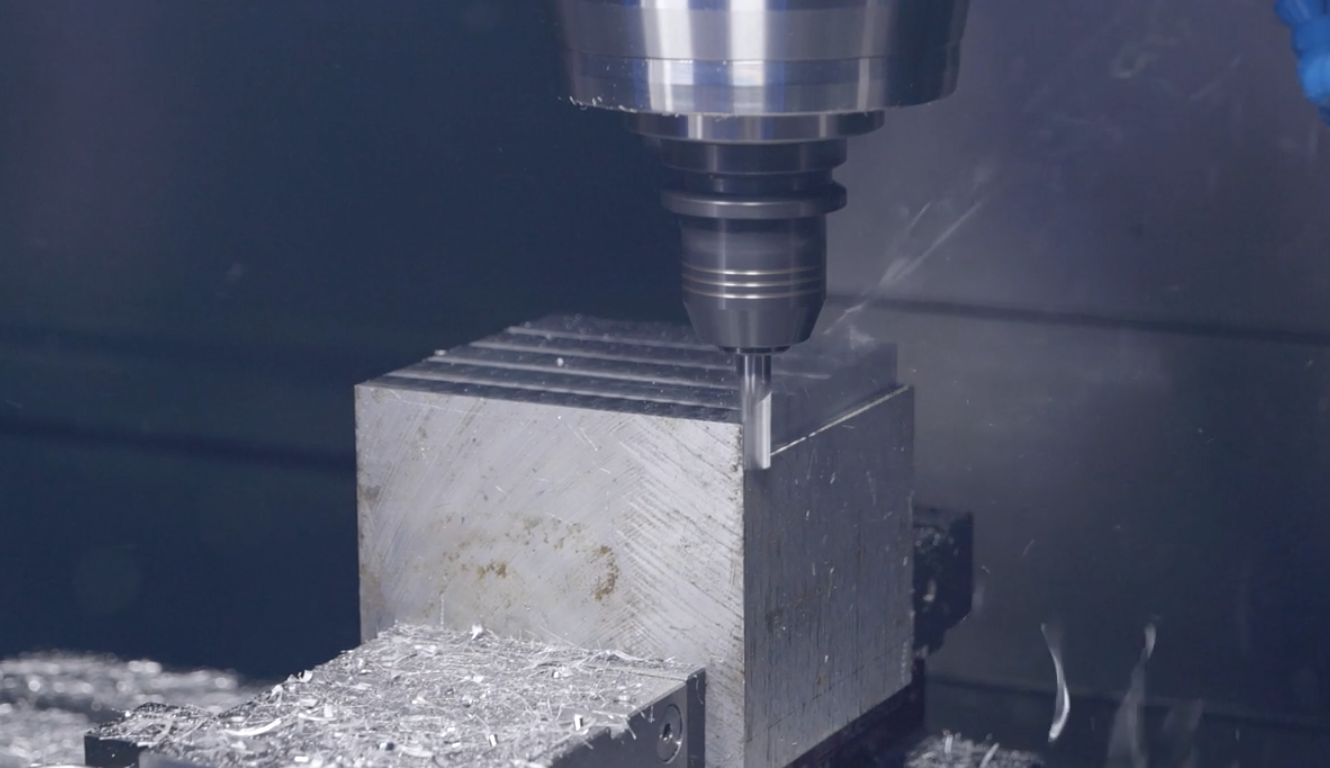

Takumi’s PV66 and PV1052 are designed for manufacturers that machine a wide range of different components within various sectors – a perfect all-purpose machining centre. Both models come with direct drive BBT40 face & taper spindles and speeds of 12,000 rpm.

Starting with the PV66, which is the smaller version of the two with a machine footprint of less than 4M², it has X, Y & Z travels of 660 x 406 x 508 mm and a table dimension of 762 x 406 mm, perfect for manufacturers that have little room in their facility but require large workpiece capacity.

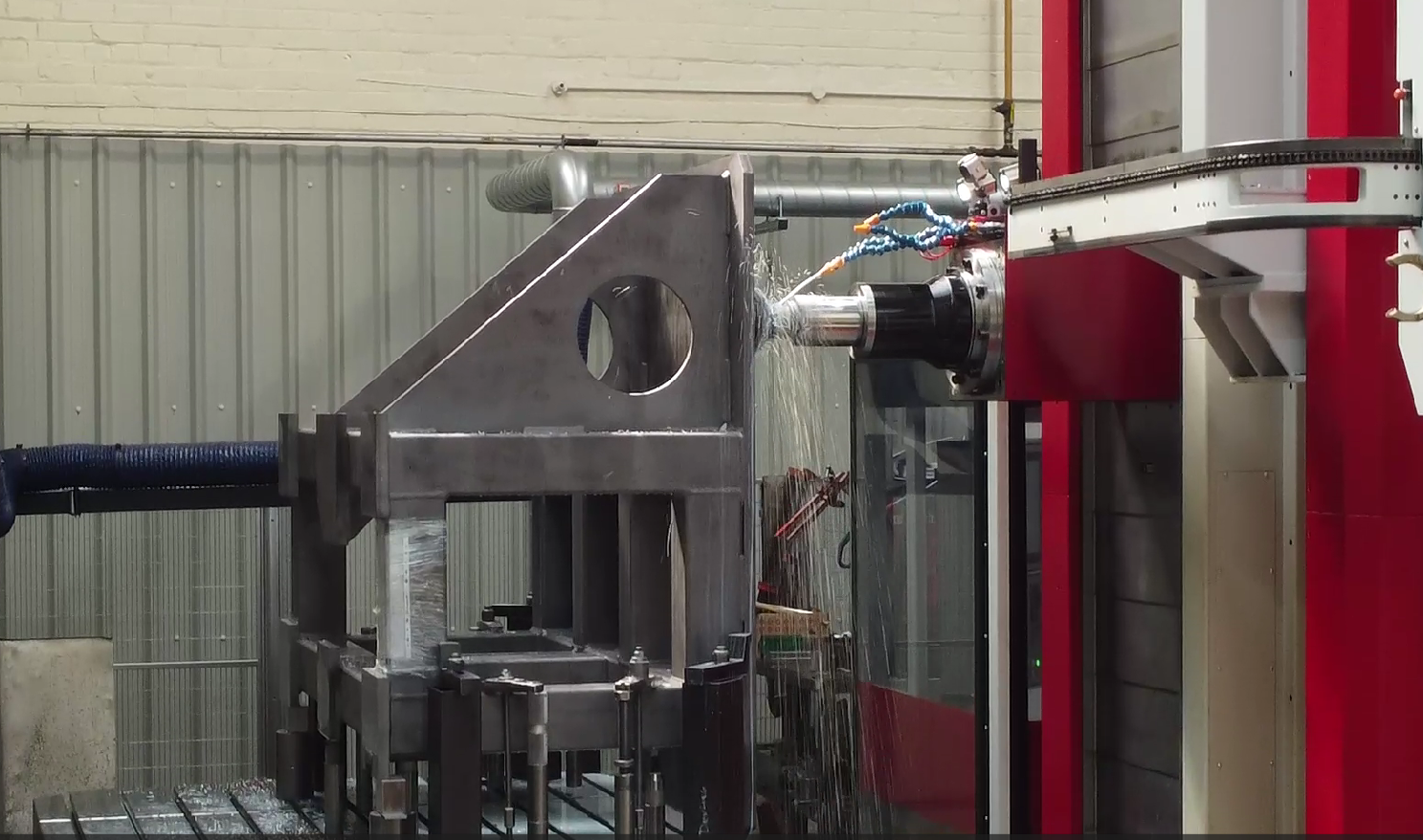

Take a look at the PV66 in action –

The larger PV1052, with a machine footprint of less than 6M², has X, Y & Z travels of 1060 x 520 x 610 mm and table dimension of 1160 x 520 mm. With a load capacity of 650 kg, it has an arm-type tool changer with a capacity of 24 tools as standard.

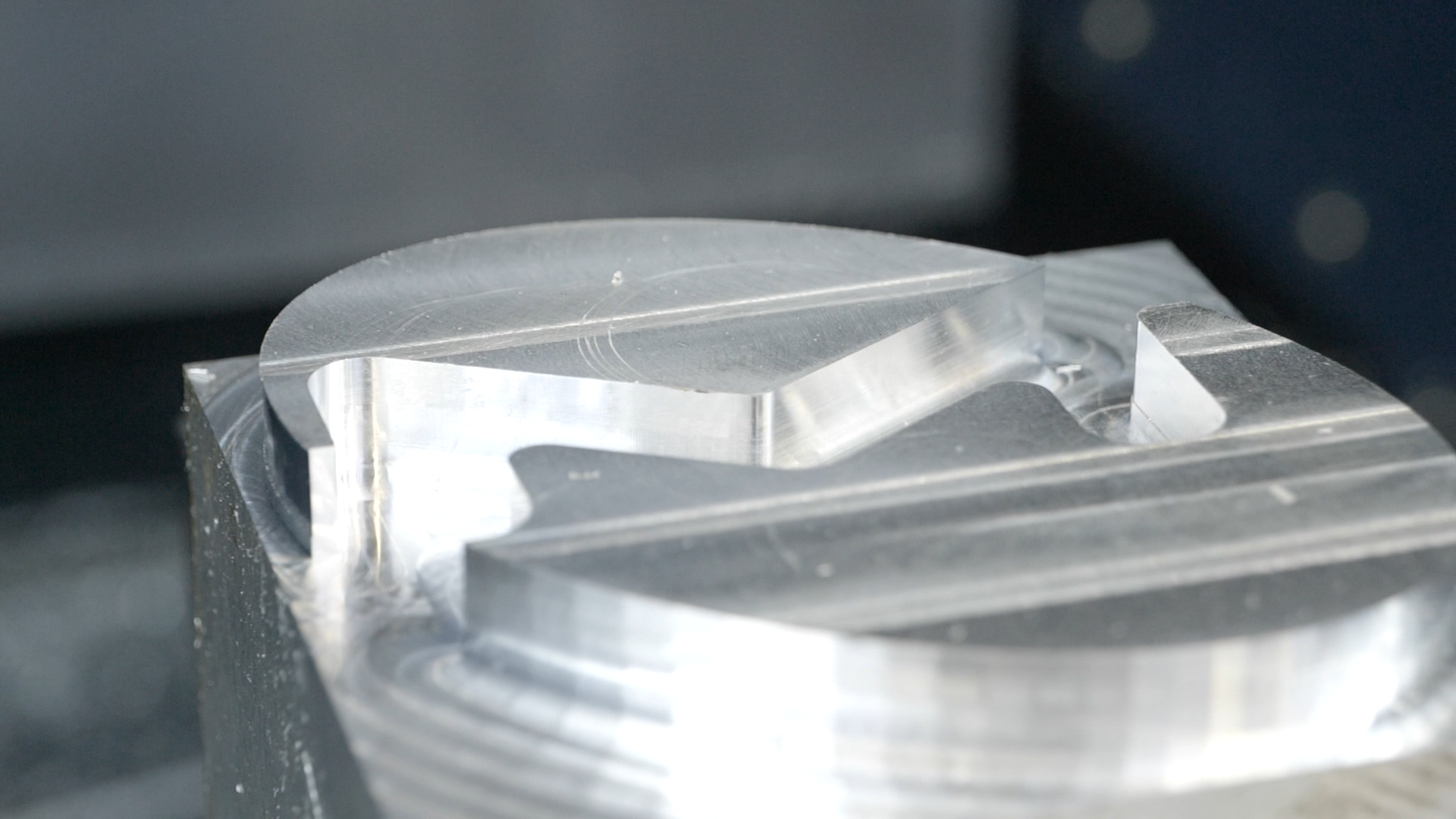

Takumi pride themselves in the design element of manufacturing such sophisticated and precise machines. The single-piece bed, columns, saddle and other main castings are made of Meehanite high grade cast iron, heat treated to remove internal stresses to ensure the best structural stability and positioning accuracy.