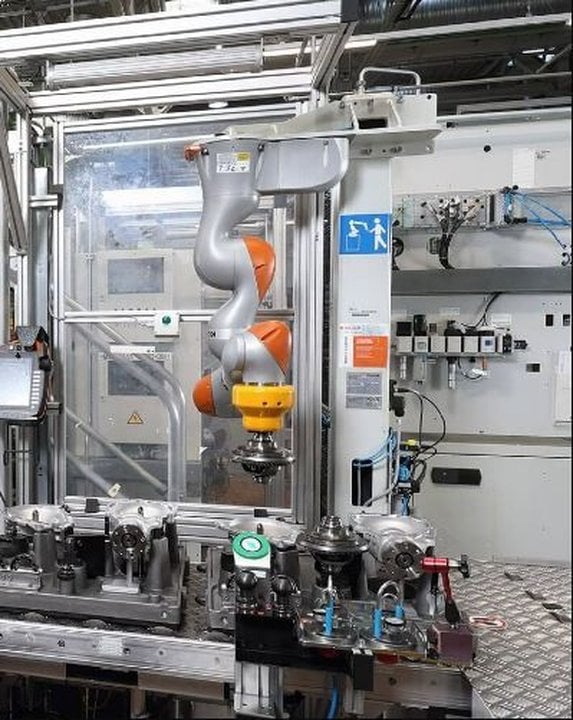

KUKA has unveiled a groundbreaking human-robot collaboration (HRC) solution featuring their advanced lightweight robot, the LBR iiwa. The innovation is set to transform manufacturing environments where space is at a premium by integrating powerful robotics into existing production lines without requiring additional room.

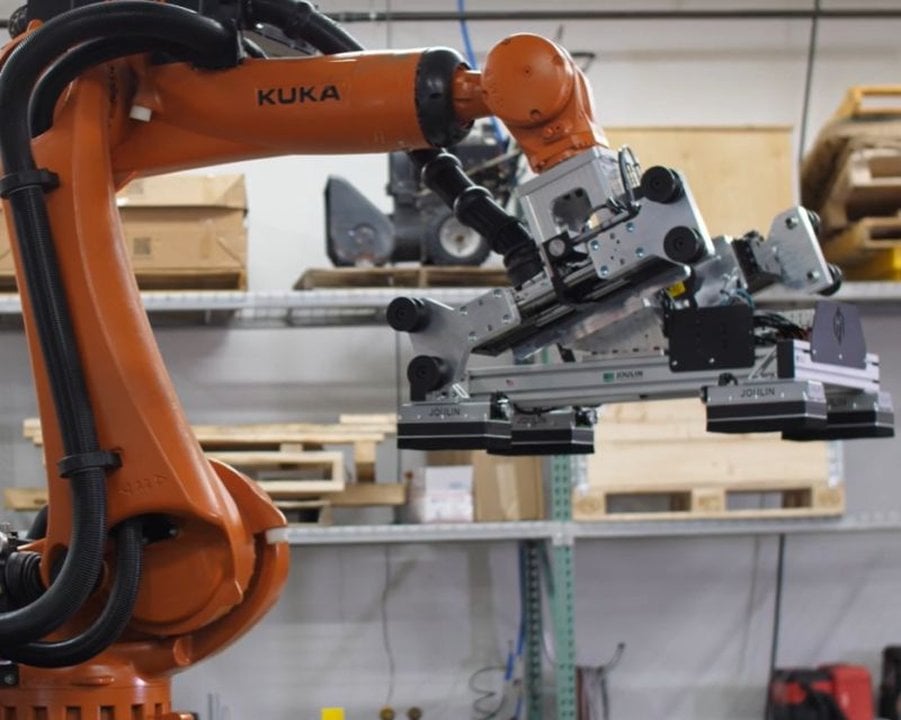

This sensitive robot is designed to handle tasks that are both ergonomically demanding and repetitive, such as the precise insertion of heavy components. By working in direct cooperation with human operators, the LBR iiwa ensures enhanced safety and delicacy during operations, redefining the interaction between humans and robots on the factory floor.

The standout feature of this solution is its space-saving steel structure, which allows the robot to be mounted overhead, maximizing the use of available space. This design not only boosts efficiency but also improves ergonomics and flexibility in modern production settings, demonstrating the potential of HRC technology to enhance productivity without the need for extensive floor space.

KUKA, known for its pioneering automation solutions, continues to lead the industry with innovations that are tailored to meet the evolving needs of manufacturing processes. The LBR iiwa is part of a broader initiative by the company to integrate advanced robotics into everyday operational contexts, pushing the boundaries of what is possible in automation.

Those interested in learning more about KUKA’s innovative solutions can explore further by visiting their website. As manufacturing environments continue to evolve, the adoption of such cutting-edge technologies is expected to become increasingly prevalent, driving efficiency and productivity to new heights.

View more news from KUKA