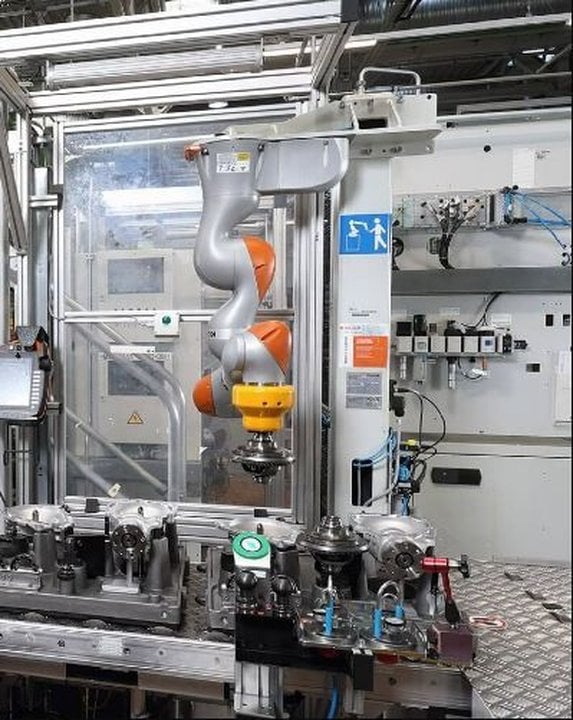

A new solution for modular assembly lines, aimed at optimizing the production of prismatic cells, is making waves in the manufacturing sector. The solution promises cost efficiency and sustainability by offering a re-use service for interim-stored production lines, without compromising on performance.

The engineering service focuses on providing customized adjustments to existing systems. It includes mechanical and electrical modifications to incorporate new components seamlessly. Additionally, the process optimization ensures a smooth transition for modular production.

Designed specifically for the handling of prismatic cells, the system architecture is flexible, allowing for future upgrades. This system became available for re-use after being decommissioned due to a change in product specifications, presenting a perfect opportunity for companies looking for customizable and efficient production lines.

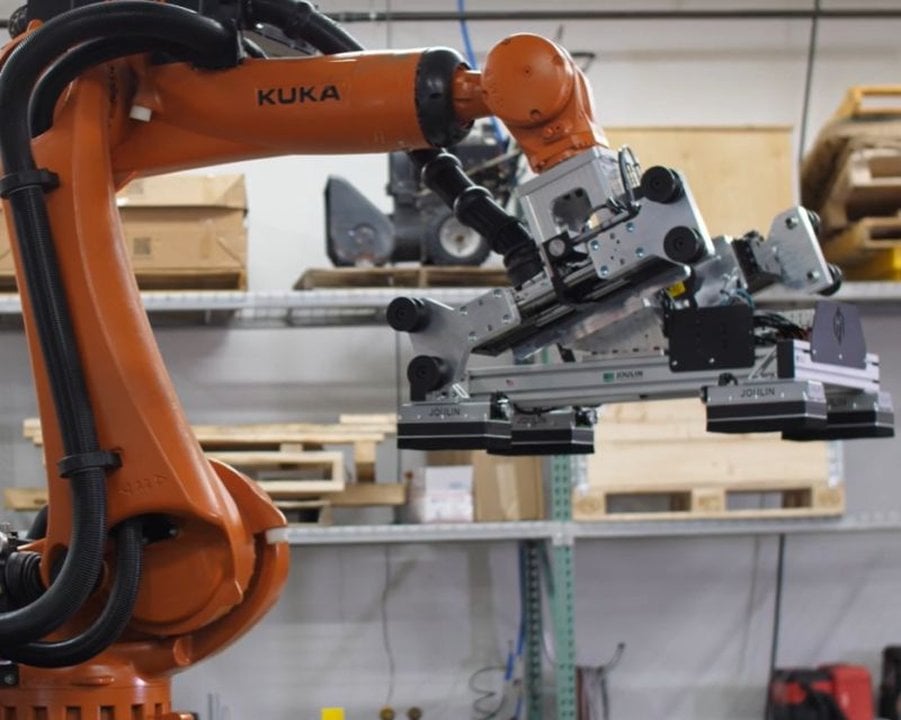

Beyond re-engineered solutions, the service offers new system design and upgrades to meet the latest industrial standards. This approach ensures that clients can choose a path that best fits their production requirements and helps accelerate the setup of their manufacturing processes.

With a commitment to enhancing efficiency and sustainability, this innovative modular assembly line solution is poised to support manufacturers in staying competitive and responsive to market changes.

View more news from KUKA