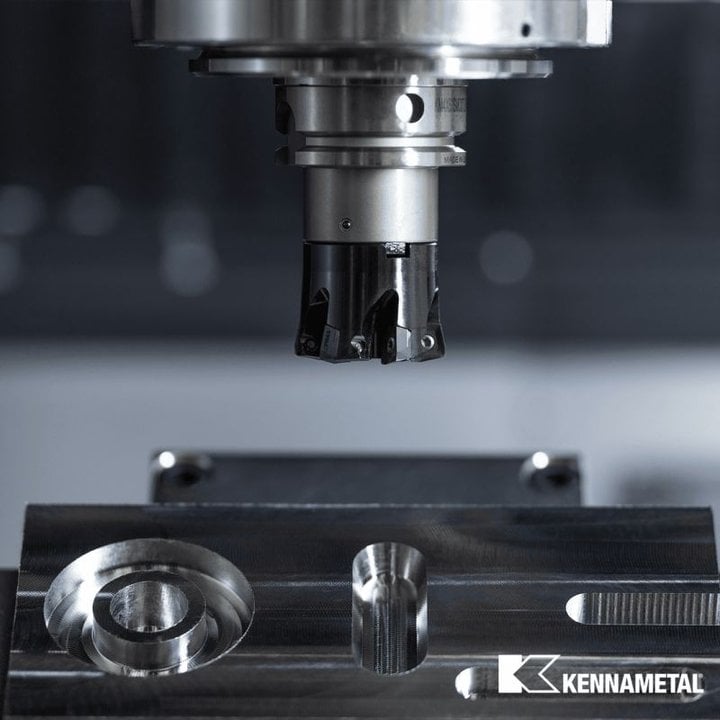

Kennametal has introduced the KSEM™ ST-Line, a new drilling solution designed to enhance manufacturing processes through improved stability and performance. This innovative product incorporates several features aimed at boosting tool life and hole quality, making it an ideal choice for the manufacturing sector.

Key features of the KSEM™ ST-Line include hydraulic clamping, which reduces vibrations, ultimately providing better tool longevity and improved hole quality. The drill’s straight shank, combined with a flange and threaded pin, offers outstanding rigidity and stiffness, fostering stability during operation. Furthermore, the strong insert clamping mechanism enhances the tool’s durability and reliability, ensuring consistent performance over time.

Additionally, the KSEM™ ST-Line is equipped with optimised coolant channels configured for Minimum Quantity Lubrication (MQL). These channels play a crucial role in enhancing cooling and lubrication, which are vital for maintaining efficient cutting conditions and prolonging tool life.

Manufacturers seeking to upgrade their shop floors can take advantage of these advancements to improve productivity and efficiency. The KSEM™ ST-Line represents Kennametal’s commitment to delivering high-quality, reliable solutions to the manufacturing industry.

Kennametal is renowned for its engineering expertise and innovative products, which have cemented its place as a leader in the tool manufacturing industry. The launch of the KSEM™ ST-Line further demonstrates its dedication to enhancing manufacturing capabilities through advanced technology.

View more news from Kennametal